Simulating Solder Joint Stress in Real-World Applications

Simulating Solder Joint Stress in Real-World Applications A Game-Changer for Businesses

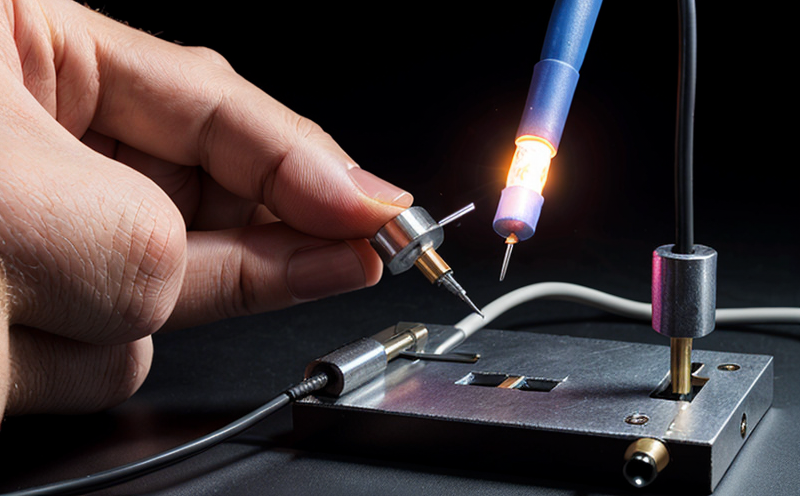

In todays fast-paced electronics industry, manufacturers are constantly pushing the boundaries of innovation and efficiency. As products become increasingly complex, the reliability of solder joints has become a critical concern. One way to mitigate this risk is through Simulating Solder Joint Stress in Real-World Applications, a cutting-edge laboratory service offered by Eurolab.

What is Simulating Solder Joint Stress in Real-World Applications?

---------------------------------------------------------

Simulating Solder Joint Stress in Real-World Applications is an advanced testing method that replicates the extreme conditions encountered by solder joints in real-world applications. By subjecting samples to simulated environmental stresses, such as temperature fluctuations, vibration, and humidity, our experts can predict how solder joints will perform under various scenarios.

This innovative approach helps manufacturers identify potential reliability issues before they become a problem, saving time, money, and resources. With Simulating Solder Joint Stress in Real-World Applications, you can

Reduce the risk of product failure Identify areas where solder joints may be prone to cracking or detachment, allowing for design improvements.

Improve product performance Understand how solder joints will respond to temperature extremes, vibration, and other environmental stresses.

Enhance customer satisfaction Deliver products that meet or exceed reliability expectations, reducing the likelihood of costly recalls.

Key Benefits of Simulating Solder Joint Stress in Real-World Applications

Our laboratory service offers numerous benefits for businesses looking to optimize their product development process. Here are some key advantages

Advantages for Manufacturers

Cost savings Identify and address potential reliability issues before they cause costly product failures.

Reduced testing time Accelerate the testing cycle by simulating real-world conditions, reducing the need for physical prototypes.

Improved quality control Ensure that products meet or exceed reliability expectations, enhancing customer satisfaction.

Advantages for Design Engineers

Increased design flexibility Understand how solder joints will respond to various environmental stresses, allowing for more informed design decisions.

Enhanced product performance Develop products that can withstand extreme conditions, improving overall efficiency and effectiveness.

Competitive edge Differentiate your products from competitors by demonstrating a commitment to reliability and quality.

Advantages for Quality Assurance Teams

Streamlined testing processes Leverage our expertise to develop targeted testing protocols, reducing the time and resources required for product testing.

Data-driven decision making Utilize our comprehensive reports to inform design and manufacturing decisions, ensuring that products meet or exceed reliability expectations.

QA Section

We understand that you may have questions about Simulating Solder Joint Stress in Real-World Applications. Here are some answers to common queries

What types of products can be tested using this service?

Eurolabs Simulating Solder Joint Stress in Real-World Applications laboratory service is suitable for a wide range of products, including electronic components, PCBs, and entire assemblies.

How does the testing process work?

Our experts will guide you through each step of the testing process, from sample preparation to report generation. Well work closely with your team to ensure that all requirements are met and that results are accurately interpreted.

What kind of data can I expect from this service?

Youll receive comprehensive reports detailing the performance of solder joints under various environmental stresses. This data will be presented in a clear, easy-to-understand format, allowing for informed decision making.

How long does the testing process take?

The length of time required for testing varies depending on the scope and complexity of the project. However, our experts will work efficiently to ensure that results are delivered as quickly as possible.

Conclusion

Simulating Solder Joint Stress in Real-World Applications is an essential service for businesses looking to optimize their product development process. By leveraging our expertise and state-of-the-art facilities, you can identify potential reliability issues before they become a problem, saving time, money, and resources. Contact Eurolab today to learn more about this groundbreaking laboratory service and discover how it can benefit your business.