Testing Solder Joint Bonding Strength to PCB Pads

Testing Solder Joint Bonding Strength to PCB Pads Ensuring Reliability and Efficiency in Your Manufacturing Process

In the ever-evolving world of electronics manufacturing, ensuring the reliability and quality of your products is paramount. One critical aspect that often goes unnoticed is the bonding strength between solder joints and printed circuit board (PCB) pads. A weak bond can lead to catastrophic failures, resulting in costly rework, waste, and damage to your reputation. Thats where Eurolab comes in a leading laboratory service provider offering expert testing solutions for Testing Solder Joint Bonding Strength to PCB Pads.

What is Testing Solder Joint Bonding Strength to PCB Pads?

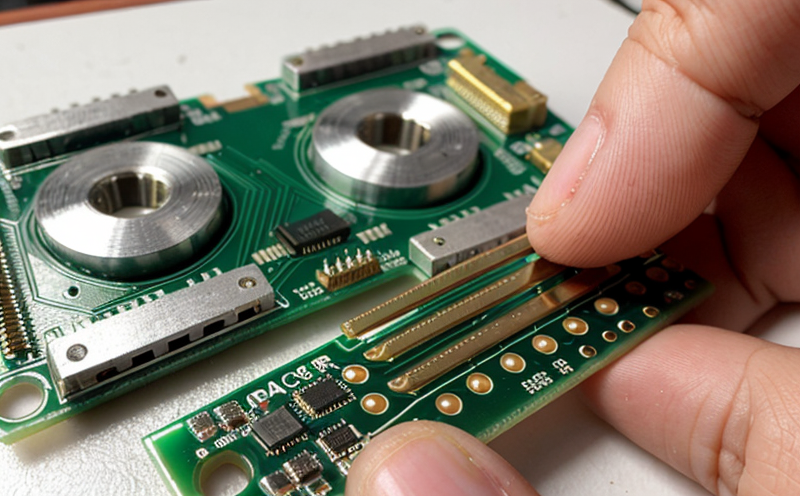

Testing Solder Joint Bonding Strength to PCB Pads involves evaluating the mechanical strength of the bond between solder joints and PCB pads. This test measures the force required to break or detach the solder joint from the pad, providing valuable insights into the reliability and durability of your products.

Why is Testing Solder Joint Bonding Strength to PCB Pads Essential for Businesses?

In todays competitive market, manufacturers must ensure that their products meet the highest standards of quality and reliability. A robust testing process can help businesses

Reduce Warranty Claims By identifying potential weaknesses in solder joints, you can minimize warranty claims and associated costs.

Increase Product Reliability Testing solder joint bonding strength ensures that your products are more resistant to mechanical stress, environmental conditions, and other factors that can cause failure.

Optimize Manufacturing Processes Identifying areas for improvement in your manufacturing process enables you to refine and streamline operations, reducing waste and increasing efficiency.

Key Benefits of Using Eurolabs Testing Solder Joint Bonding Strength to PCB Pads Service

Our expert laboratory technicians utilize state-of-the-art equipment and techniques to provide comprehensive testing services that cater to the specific needs of your business. Some key benefits include

Accurate Results Our experienced team ensures precise and reliable results, providing you with actionable data to inform your manufacturing decisions.

Customized Testing Solutions We offer tailored testing protocols to suit your unique requirements, from standard testing procedures to customized methods for complex products.

Rapid Turnaround Times With our efficient testing process, you can expect fast turnaround times without compromising on accuracy or quality.

Compliance with Industry Standards Our testing services adhere to industry-recognized standards and regulations, ensuring that your products meet the required specifications.

How Does Testing Solder Joint Bonding Strength to PCB Pads Benefit Your Business?

By incorporating this essential test into your manufacturing process, you can

Improve Product Yield By identifying and addressing potential weaknesses in solder joints, you can minimize defects and increase product yield.

Enhance Quality Control Regular testing enables you to monitor the performance of your products over time, allowing for early detection of issues and prompt corrective action.

Reduce Manufacturing Costs By minimizing rework and reducing waste, you can optimize manufacturing processes and lower costs associated with product failure.

Frequently Asked Questions (FAQs)

We understand that you may have questions about our Testing Solder Joint Bonding Strength to PCB Pads service. Here are some answers to frequently asked questions

Q What types of products require testing solder joint bonding strength?

A Any electronic device or component with solder joints and PCB pads, including but not limited to, printed circuit boards (PCBs), connectors, and wire bonds.

Q How do you conduct the testing process?

A Our expert technicians use specialized equipment, such as universal testing machines, to apply a controlled force to the solder joint while monitoring its deformation and failure.

Q What types of materials can be tested using this service?

A We can test various materials, including but not limited to, tin-silver-copper (SnAgCu) solder, lead-free solder, and other alloys.

Q How long does the testing process typically take?

A The duration of testing depends on the specific requirements of your product. However, our rapid turnaround times ensure that you receive results promptly without compromising on quality or accuracy.

Conclusion

In todays competitive electronics manufacturing landscape, ensuring the reliability and quality of your products is crucial. By incorporating Eurolabs Testing Solder Joint Bonding Strength to PCB Pads service into your testing regimen, you can

Reduce warranty claims and associated costs

Increase product reliability and durability

Optimize manufacturing processes for improved efficiency and reduced waste

Dont compromise on the quality of your products partner with Eurolab today to ensure that your solder joints meet the highest standards.