X-Ray Inspection of Solder Joints for Defects

Unlock the Secrets of Your Solder Joints X-Ray Inspection for Defects with Eurolab

In todays fast-paced world of electronics manufacturing, quality control is paramount to ensuring the reliability and performance of your products. One critical aspect of electronic assembly that often goes unnoticed until its too late is the integrity of solder joints. A single defective joint can lead to catastrophic failures, costly rework, and damaged reputation. Thats where X-Ray Inspection of Solder Joints for Defects comes in a cutting-edge laboratory service provided by Eurolab, designed to detect even the most subtle defects before they become major issues.

What is X-Ray Inspection of Solder Joints for Defects?

X-Ray Inspection of Solder Joints for Defects is a non-destructive testing (NDT) method that uses high-energy X-rays to penetrate and visualize solder joints, enabling the detection of internal defects such as

Porosity

Lack of fusion

Insufficient wetting

Inclusions

Delamination

By utilizing advanced X-ray technology, Eurolabs experts can inspect your solder joints with unparalleled precision, providing you with accurate reports on their integrity.

Why is X-Ray Inspection of Solder Joints for Defects Essential?

In todays highly competitive electronics market, the stakes are high. A single defective joint can lead to

Costly rework Identifying and correcting defects after assembly can be time-consuming and expensive.

Damage to reputation Product failures due to solder joint defects can irreparably harm your brands credibility.

Production downtime Detecting defects early on allows for swift corrective action, minimizing the risk of production halts.

The benefits of X-Ray Inspection of Solder Joints for Defects extend far beyond just quality control. Here are some key advantages

Benefits of X-Ray Inspection of Solder Joints for Defects

Improved product reliability By identifying defects early on, you can prevent costly failures and ensure your products meet industry standards.

Enhanced production efficiency With Eurolabs rapid turnaround times, youll save time and resources by detecting issues before they impact your assembly lines.

Compliance with industry regulations Regular X-Ray Inspection of Solder Joints for Defects ensures compliance with industry standards, reducing the risk of regulatory non-compliance.

How Does X-Ray Inspection of Solder Joints for Defects Work?

The process is straightforward

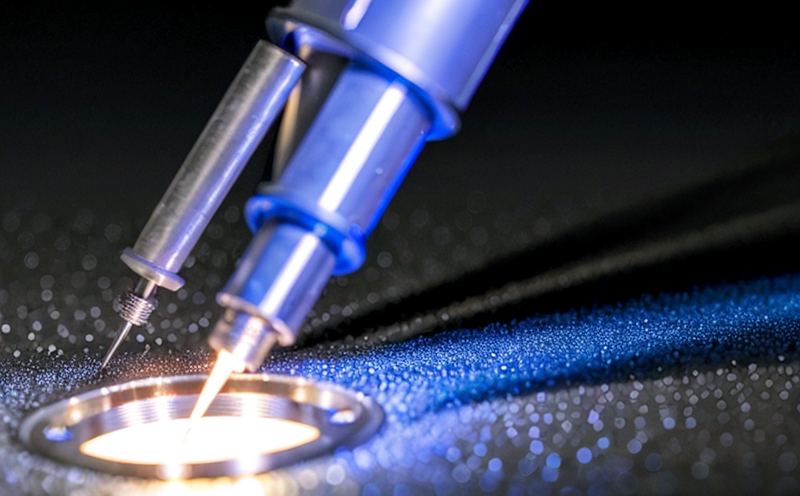

Sample preparation Your assembly samples are carefully prepared and positioned within our state-of-the-art X-ray inspection chamber.

X-ray scanning Our advanced X-ray equipment scans the solder joints, generating high-resolution images that reveal any defects or irregularities.

Data analysis Our experts analyze the data to identify any potential issues.

Eurolabs State-of-the-Art Facilities and Expertise

At Eurolab, we pride ourselves on

Cutting-edge technology Our X-ray inspection equipment is regularly updated to ensure the highest level of accuracy.

Industry-recognized expertise Our team consists of highly trained professionals with extensive experience in NDT and solder joint analysis.

Frequently Asked Questions (FAQs)

Q What types of materials can be inspected using X-Ray Inspection of Solder Joints for Defects?

A Our X-ray inspection chamber is capable of inspecting a wide range of materials, including lead-free solders.

Q How long does the X-Ray Inspection process take?

A Turnaround times vary depending on the complexity and size of your assembly samples. However, our team strives to provide rapid turnaround without compromising quality.

Q Can I send my samples directly to Eurolab for inspection?

A Yes, simply package your samples securely and ship them to us using a trackable shipping method.

Q Will X-Ray Inspection damage my samples or affect their integrity?

A Our X-ray inspection process is non-destructive, meaning it wont harm or alter the integrity of your assembly samples.

Conclusion

In conclusion, X-Ray Inspection of Solder Joints for Defects with Eurolab offers unparalleled benefits in terms of product reliability, production efficiency, and compliance. By partnering with us, youll be able to

Reduce costly rework and failures

Protect your brands reputation

Ensure regulatory compliance

Dont wait until its too late trust Eurolab to provide accurate and reliable X-Ray Inspection of Solder Joints for Defects services. Contact us today to learn more about our laboratory services!