Evaluating the shear strength of medical device materials

Evaluating the Shear Strength of Medical Device Materials A Crucial Laboratory Service for Businesses

As medical device manufacturers strive to create innovative and reliable products that meet stringent regulatory requirements, evaluating the shear strength of medical device materials has become an essential laboratory service. At Eurolab, our expert technicians provide this critical evaluation service to help businesses ensure their products safety and efficacy.

What is Shear Strength?

Shear strength refers to a materials resistance to deformation under stress when subjected to a shearing force. This fundamental property is crucial for medical device manufacturers, as it directly impacts the products functionality, durability, and patient safety. A material with high shear strength can withstand the stresses of daily use, while one with low shear strength may break or fail, leading to adverse consequences.

Why is Evaluating Shear Strength Essential for Medical Device Manufacturers?

Evaluating the shear strength of medical device materials is vital for several reasons

Ensures Product Safety By testing material properties, manufacturers can identify potential risks and ensure their products meet regulatory standards.

Optimizes Material Selection Understanding a materials shear strength enables manufacturers to choose the best-suited materials for specific applications, reducing the risk of product failure.

Reduces Liability Demonstrating compliance with industry regulations and safety standards through shear strength evaluation can mitigate liability risks associated with product recalls or injuries.

Key Benefits of Evaluating Shear Strength at Eurolab

Our laboratory service provides numerous benefits to medical device manufacturers

Benefits for Manufacturers

Compliance with Regulatory Requirements Our evaluations ensure that products meet industry standards and regulatory requirements, reducing the risk of non-compliance.

Improved Product Reliability By understanding material properties, manufacturers can design more reliable products that minimize the risk of failure.

Reduced Testing Time and Costs Our experienced technicians perform shear strength evaluations efficiently, saving time and resources for our clients.

Enhanced Customer Confidence Demonstrating a commitment to product safety through rigorous testing fosters trust with customers and stakeholders.

Benefits for Patients

Increased Safety Products that undergo thorough material evaluation are less likely to cause harm or injury to patients.

Improved Treatment Outcomes Reliable medical devices contribute to better treatment results, enhancing patient satisfaction and overall well-being.

Reduced Medical Errors By minimizing the risk of product failure, manufacturers can reduce the likelihood of medical errors.

How Does Eurolabs Shear Strength Evaluation Service Work?

Our expert technicians employ advanced equipment and techniques to evaluate the shear strength of various materials. The evaluation process typically involves

Material Sample Preparation We receive material samples from our clients, which are then prepared for testing.

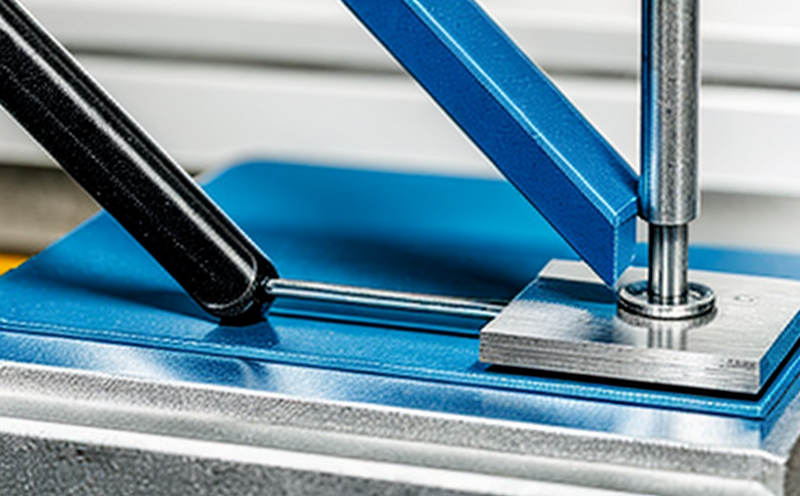

Shear Testing Our experienced technicians conduct shear tests using specialized equipment, such as universal testing machines or torsion testers.

Data Analysis and Reporting We analyze the test results, providing detailed reports on the materials shear strength properties.

Frequently Asked Questions (FAQs)

Q What types of materials can be evaluated for shear strength?

A Eurolab evaluates various materials used in medical devices, including metals, polymers, ceramics, and composites.

Q How long does the evaluation process take?

A The duration of the evaluation depends on the complexity of the test and the number of samples. Typically, results are available within 2-5 business days.

Q Are your technicians certified or experienced in material testing?

A Yes, our technicians have extensive experience in material testing and hold relevant certifications to ensure accurate and reliable results.

Q Can I request specific testing protocols or procedures?

A Absolutely. Our clients can specify customized testing protocols or procedures tailored to their unique requirements.

Conclusion

Evaluating the shear strength of medical device materials is a critical laboratory service that ensures product safety, optimizes material selection, and reduces liability risks for manufacturers. At Eurolab, we provide expert technicians, advanced equipment, and comprehensive reporting to help businesses meet industry standards and regulatory requirements. By choosing our laboratory service, you can trust your products reliability and safety, ultimately benefiting patients and driving business success.

Evaluating the shear strength of medical device materials is a vital step in ensuring product safety and compliance with industry regulations. At Eurolab, we offer expert technicians, advanced equipment, and comprehensive reporting to help businesses meet regulatory requirements. By choosing our laboratory service, manufacturers can trust their products reliability and safety, ultimately benefiting patients and driving business success.

We are committed to providing exceptional services that meet the evolving needs of medical device manufacturers. Contact us today to learn more about how our shear strength evaluation service can support your business goals.