Mechanical strength testing of implantable medical devices

The Critical Role of Mechanical Strength Testing in Ensuring the Reliability of Implantable Medical Devices

As medical technology advances at a rapid pace, the demand for implantable devices has grown exponentially. From pacemakers and prosthetics to dental implants and surgical meshes, these innovative solutions have revolutionized the way we treat various medical conditions. However, with increased complexity comes heightened responsibility, particularly when it comes to ensuring the safety and efficacy of these life-changing devices.

What is Mechanical Strength Testing of Implantable Medical Devices?

Mechanical strength testing of implantable medical devices is a crucial laboratory service that evaluates the durability and reliability of these products under various mechanical stresses. This comprehensive testing process involves subjecting samples to a range of forces, including tensile, compressive, bending, and impact loads, to assess their ability to withstand expected in-use conditions.

At Eurolab, our team of expert technicians utilizes cutting-edge equipment and proven methodologies to simulate the real-world stressors that implantable devices may encounter. This rigorous testing ensures that products meet or exceed regulatory standards, reducing the risk of device failure, injury, or even death.

Why is Mechanical Strength Testing Essential for Businesses?

In todays highly competitive medical device market, manufacturers must prioritize product safety and performance to maintain customer trust and regulatory compliance. By investing in mechanical strength testing of implantable medical devices, businesses can

Reduce the Risk of Device Failure Identifying potential weaknesses early on enables companies to redesign or re-engineer products, minimizing the likelihood of costly recalls and damage to their reputation.

Ensure Regulatory Compliance Meeting stringent standards set by regulatory bodies such as FDA, CE, and ISO ensures that products are safe for use in humans. Non-compliance can result in severe penalties, fines, and even product bans.

Enhance Product Reliability By testing devices under real-world conditions, manufacturers can ensure that they will perform consistently and reliably over time, reducing the risk of patient injury or death.

Gain Competitive Advantage Companies that prioritize product safety and performance stand to gain a significant competitive edge in the market, attracting customers who value reliable, high-quality products.

What are the Benefits of Mechanical Strength Testing?

Our comprehensive mechanical strength testing services offer numerous benefits to medical device manufacturers, including

Reduced Time-to-Market By identifying potential issues early on, companies can accelerate product development and get their devices to market faster, reducing time-to-market and increasing revenue.

Improved Product Design Our expert technicians provide valuable insights into the mechanical properties of implantable devices, enabling manufacturers to optimize design and materials for improved performance and durability.

Enhanced Customer Trust By demonstrating a commitment to product safety and reliability, companies can build strong relationships with customers, driving loyalty and repeat business.

Reduced Liability Manufacturers who invest in mechanical strength testing can mitigate the risk of product-related claims and lawsuits, protecting their reputation and bottom line.

Frequently Asked Questions

What types of implantable medical devices do you test?

At Eurolab, we offer mechanical strength testing for a wide range of implantable devices, including pacemakers, prosthetics, dental implants, surgical meshes, and more.

How does your testing process ensure regulatory compliance?

Our comprehensive testing protocols are designed to meet or exceed international standards (e.g., ISO 10993-7), ensuring that our results are reliable and compliant with regulatory requirements.

What kind of equipment do you use for mechanical strength testing?

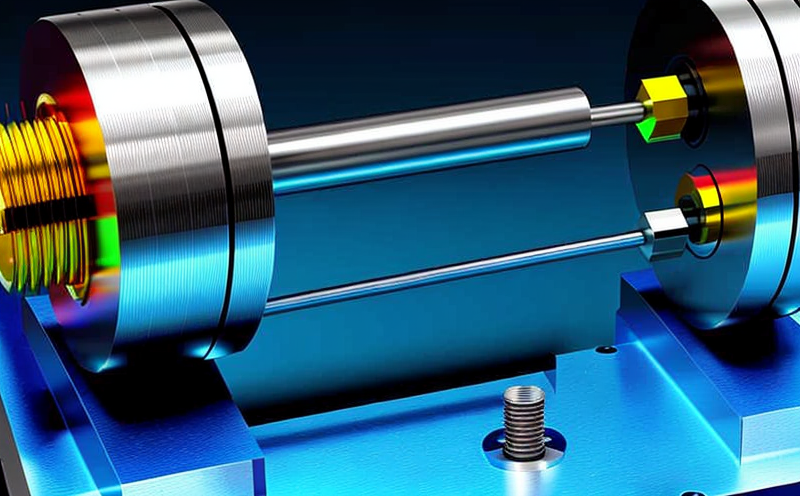

We utilize cutting-edge testing machinery, including tensile testers, compressive machines, bending fixtures, and impact testing apparatus to simulate real-world stressors on implantable devices.

Can I get a copy of my test report or certificate of compliance?

Yes! We provide detailed reports and certificates of compliance for all tests conducted at Eurolab. These documents serve as valuable tools for regulatory submissions, product labeling, and marketing materials.

How long does the testing process typically take?

The duration of our mechanical strength testing services varies depending on the type of device and complexity of testing required. We work closely with clients to develop customized testing plans that meet their specific needs and timelines.

Do you offer any additional testing or certification services?

Yes! Our comprehensive laboratory services include a range of other tests, such as biocompatibility, sterilization validation, and packaging integrity assessment. We also provide expert witness testimony and product failure analysis services.

Conclusion

Mechanical strength testing of implantable medical devices is an indispensable step in ensuring the safety and reliability of these life-changing products. At Eurolab, our team of experts is dedicated to providing comprehensive laboratory services that meet or exceed regulatory standards, helping manufacturers reduce risk, enhance customer trust, and drive business success.

Whether youre a seasoned medical device manufacturer or a startup looking to bring innovative solutions to market, we invite you to explore the benefits of our mechanical strength testing services. By investing in product safety and performance, youll be taking a critical step towards building a reputation as a trusted leader in the industry.