Mechanical testing of medical devices for impact during use

The Critical Role of Mechanical Testing for Medical Devices Ensuring Safety and Compliance

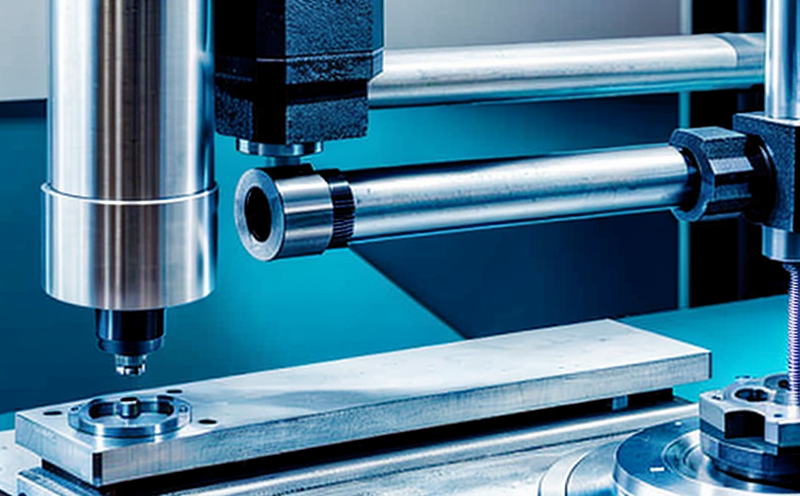

In the rapidly evolving world of medical device manufacturing, ensuring the safety and effectiveness of products is paramount. One critical aspect of this endeavor is mechanical testing of medical devices for impact during use. This specialized service helps businesses guarantee that their products can withstand the rigors of real-world usage without compromising patient safety or product performance.

At Eurolab, our team of experts provides high-quality mechanical testing services tailored to meet the unique demands of medical device manufacturers. In this article, well delve into the importance of mechanical testing for impact during use, highlighting its benefits and exploring key aspects of this crucial process.

What is Mechanical Testing of Medical Devices for Impact During Use?

Mechanical testing of medical devices involves evaluating their ability to withstand various forms of physical stress, including impacts. This type of testing ensures that products can endure the rigors of everyday use without suffering damage or compromising patient safety.

Impact testing for medical devices typically includes a range of evaluations, such as

Drop testing simulating falls from specified heights to assess product durability and resistance to impact

Compression testing evaluating the ability of products to withstand crushing forces

Tension testing assessing tensile strength and resistance to deformation under load

These tests help identify potential weaknesses in design or materials, enabling manufacturers to make informed decisions about product improvements.

The Advantages of Mechanical Testing for Medical Devices

Incorporating mechanical testing into your quality control process offers numerous benefits for medical device manufacturers. Here are some key advantages

Ensures Patient Safety By simulating real-world scenarios, mechanical testing helps identify potential hazards and ensures that products can withstand the stresses of use without compromising patient safety.

Compliance with Regulations Mechanical testing is essential for meeting regulatory requirements, such as those outlined by the US FDA and EU MDR. Our team at Eurolab ensures that your products meet or exceed these standards.

Reduces Liability Risk By identifying potential weaknesses and implementing design improvements, mechanical testing can significantly reduce liability risks associated with product failure.

Enhances Product Reliability Regular mechanical testing helps manufacturers maintain product reliability, reducing the likelihood of product recalls and ensuring a positive brand reputation.

Key Benefits of Mechanical Testing at Eurolab

At Eurolab, our comprehensive mechanical testing services provide medical device manufacturers with

Expertise Our team consists of highly trained professionals with extensive experience in mechanical testing for medical devices.

State-of-the-Art Equipment We utilize the latest technology and equipment to ensure accurate and reliable test results.

Customized Testing Solutions We work closely with clients to develop tailored testing protocols that meet specific product requirements.

Rapid Turnaround Times Our efficient testing process ensures minimal downtime for your products, allowing you to get them back on the market quickly.

QA Frequently Asked Questions about Mechanical Testing of Medical Devices

Q1 What types of medical devices require mechanical testing?

A1 All medical devices that are subject to physical stress during use, such as surgical instruments, implantable devices, and diagnostic equipment.

Q2 How do I know if my product needs impact testing?

A2 If your product is prone to physical wear or has a high risk of damage due to handling, transportation, or use, it may require mechanical testing.

Q3 What are the costs associated with mechanical testing?

A3 The cost of mechanical testing varies depending on the scope and complexity of the test protocol. We offer competitive pricing and flexible payment options to accommodate your business needs.

Q4 Can you provide testing services for both prototype and production products?

A4 Yes, our team at Eurolab can provide testing services for prototypes as well as production products, ensuring that your products meet or exceed regulatory requirements throughout the product lifecycle.

Conclusion

In the highly competitive world of medical device manufacturing, ensuring the safety and effectiveness of products is paramount. Mechanical testing for impact during use is a critical aspect of this endeavor, helping manufacturers identify potential weaknesses and ensure compliance with regulations.

At Eurolab, our comprehensive mechanical testing services provide medical device manufacturers with expert guidance, state-of-the-art equipment, and customized testing solutions tailored to meet specific product requirements. By partnering with us, you can rest assured that your products will meet or exceed regulatory standards, protecting patient safety and minimizing liability risks.

Dont compromise on the quality and reliability of your medical devices. Contact Eurolab today to learn more about our mechanical testing services and take the first step towards ensuring the safety and effectiveness of your products.