Mechanical Strength Testing

The Crucial Role of Mechanical Strength Testing in Ensuring Product Reliability

In todays highly competitive and regulated business landscape, ensuring the reliability and durability of products is no longer a nicety its a necessity. One critical laboratory service that plays a vital role in this pursuit is Mechanical Strength Testing, offered by Eurolab. This specialized testing procedure evaluates the mechanical properties of materials under various conditions, providing invaluable insights into their performance and safety.

As a leading provider of laboratory services, Eurolab understands the importance of accurate and reliable data in making informed decisions about product development, quality control, and regulatory compliance. In this article, well delve into the world of Mechanical Strength Testing, exploring its benefits, applications, and significance for businesses seeking to maintain their competitive edge.

What is Mechanical Strength Testing?

Mechanical Strength Testing is a comprehensive evaluation process that assesses the mechanical properties of materials, including metals, plastics, ceramics, and composites. This testing procedure involves subjecting samples to various mechanical loads, such as tension, compression, bending, torsion, and impact, to determine their resistance to deformation, fracture, or failure.

The tests are designed to simulate real-world conditions, allowing manufacturers to understand how their products will perform under stress, temperature fluctuations, and other environmental factors. By identifying potential weaknesses and vulnerabilities, businesses can refine their product designs, materials selection, and manufacturing processes to ensure superior performance, safety, and reliability.

Advantages of Mechanical Strength Testing

The benefits of Mechanical Strength Testing are multifaceted and far-reaching, offering numerous advantages for businesses across various industries. Some key benefits include

Improved Product Reliability By identifying potential weaknesses and vulnerabilities, manufacturers can refine their product designs to ensure superior performance and safety.

Enhanced Regulatory Compliance Mechanical Strength Testing helps businesses meet industry-specific regulations and standards, reducing the risk of non-compliance and associated fines or penalties.

Increased Efficiency Accurate and reliable data enables informed decision-making, streamlining product development, quality control, and manufacturing processes.

Cost Savings Identifying potential issues early on can save businesses from costly rework, waste, and recall initiatives.

Competitive Advantage Companies that prioritize mechanical strength testing demonstrate a commitment to excellence, enhancing their reputation and competitiveness in the market.

Informed Material Selection Mechanical Strength Testing helps manufacturers choose materials with optimal properties for their specific applications, reducing material waste and optimizing production costs.

Key Benefits of Mechanical Strength Testing

Compliance with Industry Standards Eurolabs mechanical strength testing services ensure compliance with industry-specific regulations and standards, such as ASTM, ISO, and EN.

Customized Testing Programs Our team works closely with clients to develop tailored testing programs that meet their unique requirements and address specific product or material concerns.

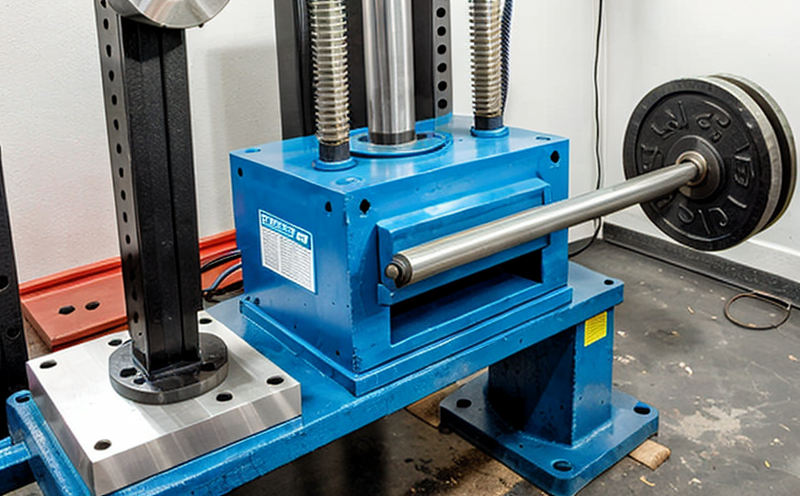

State-of-the-Art Equipment Eurolabs laboratory is equipped with cutting-edge equipment and technology, ensuring accurate and reliable results.

Expert Analysis and Reporting Our experienced technicians provide comprehensive analysis and reporting, facilitating informed decision-making and swift implementation of test recommendations.

QA Frequently Asked Questions about Mechanical Strength Testing

What types of materials can be tested using Mechanical Strength Testing?

Eurolabs mechanical strength testing services are applicable to a wide range of materials, including metals (e.g., aluminum, steel), plastics (e.g., polypropylene, polycarbonate), ceramics, and composites.

How long does the testing process typically take?

The duration of Mechanical Strength Testing varies depending on the specific test method, sample preparation, and client requirements. However, most tests can be completed within a few days to several weeks.

Can Eurolab provide customized testing programs for my business?

Yes, our team is committed to understanding your unique needs and developing tailored testing programs that address your product or material concerns.

How do I choose the right Mechanical Strength Testing service provider?

When selecting a laboratory partner, look for expertise in mechanical strength testing, cutting-edge equipment, and a commitment to delivering accurate and reliable results.

What kind of data can I expect from Eurolabs Mechanical Strength Testing services?

Our comprehensive reporting includes detailed analysis and recommendations, enabling you to make informed decisions about product development, quality control, and regulatory compliance.

Conclusion

In todays fast-paced business environment, ensuring the reliability and durability of products is no longer a nicety its a necessity. By leveraging Eurolabs Mechanical Strength Testing services, businesses can gain invaluable insights into their materials performance and safety, driving informed decision-making and competitive success.

Whether youre looking to improve product reliability, enhance regulatory compliance, or optimize material selection, our team of experts is committed to delivering cutting-edge testing solutions that meet your unique needs. Contact us today to learn more about how Mechanical Strength Testing can elevate your businesss performance and reputation.