Impact of Mechanical Shocks on Lens Optical Properties

The Critical Importance of Assessing Impact of Mechanical Shocks on Lens Optical Properties A Game-Changer for Businesses

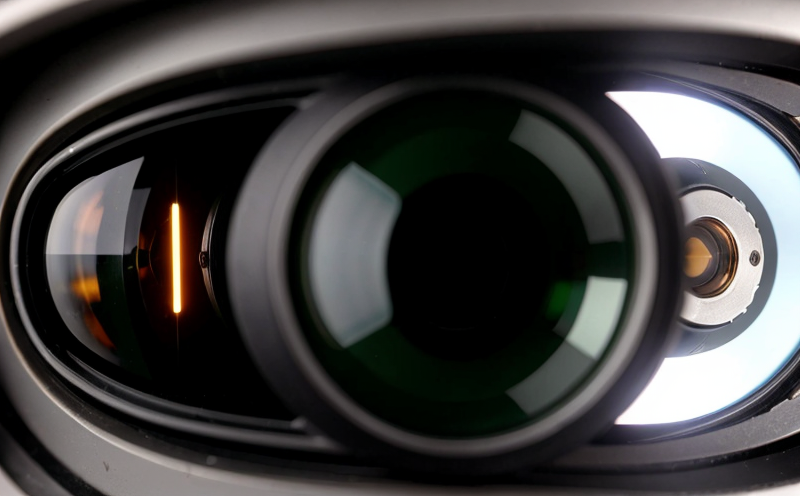

In todays fast-paced and highly competitive world, businesses are constantly striving to stay ahead of the curve. One crucial aspect that can make or break a product is its optical quality. Optical components, particularly lenses, play a vital role in various industries, including aerospace, defense, automotive, and consumer electronics. However, these components are susceptible to mechanical shocks, which can significantly impact their optical properties.

Mechanical shocks refer to sudden, intense vibrations or impacts that can cause damage to the lenss internal structure, leading to changes in its optical behavior. This phenomenon is a significant concern for businesses, as it can result in reduced product performance, increased maintenance costs, and even product failure.

What is Impact of Mechanical Shocks on Lens Optical Properties?

Impact of Mechanical Shocks on Lens Optical Properties is a laboratory service offered by Eurolab that assesses the effects of mechanical shocks on optical lenses. Our team of expert engineers uses advanced equipment to simulate various types of mechanical shocks, including drop tests, vibration tests, and acoustic tests. The results provide valuable insights into how the lenss optical properties change under different shock conditions.

Why is Impact of Mechanical Shocks on Lens Optical Properties Essential for Businesses?

The importance of assessing Impact of Mechanical Shocks on Lens Optical Properties cannot be overstated. Here are some key benefits that make this service a game-changer for businesses

Improved Product Reliability By simulating mechanical shocks, Eurolabs laboratory service helps identify potential issues with lens optical properties, enabling manufacturers to design more robust and reliable products.

Reduced Maintenance Costs Regular assessments can help detect early signs of damage or degradation, allowing maintenance teams to take corrective action before costly repairs are required.

Increased Product Performance By understanding how mechanical shocks affect lens optical properties, businesses can optimize product design and manufacturing processes to minimize performance losses.

Enhanced Customer Satisfaction Products with reliable and consistent optical performance lead to increased customer satisfaction, which in turn drives business growth.

Key Benefits of Impact of Mechanical Shocks on Lens Optical Properties

Here are the key benefits of our laboratory service

Accurate Simulation of Real-World Conditions Eurolabs advanced equipment simulates a wide range of mechanical shock scenarios, ensuring that our results accurately reflect real-world conditions.

Comprehensive Data Analysis Our expert engineers provide detailed reports on lens optical properties before and after mechanical shocks, highlighting changes in performance and identifying areas for improvement.

Customized Testing Solutions Eurolab offers tailored testing solutions to meet the specific needs of each business, ensuring that our services are aligned with their unique requirements.

QA Frequently Asked Questions About Impact of Mechanical Shocks on Lens Optical Properties

Here are some frequently asked questions about our laboratory service

Q What types of mechanical shocks can be simulated in Eurolabs laboratory?

A Our equipment simulates various types of mechanical shocks, including drop tests, vibration tests, and acoustic tests.

Q How do I know if my product requires Impact of Mechanical Shocks on Lens Optical Properties testing?

A If your product involves optical components that are susceptible to mechanical shock, it is essential to conduct regular assessments to ensure optimal performance and reliability.

Q Can Eurolabs laboratory service be customized to meet specific business needs?

A Yes, our team offers tailored testing solutions to meet the unique requirements of each business.

Q What kind of data can I expect from the Impact of Mechanical Shocks on Lens Optical Properties test results?

A Our reports provide comprehensive data on lens optical properties before and after mechanical shocks, highlighting changes in performance and identifying areas for improvement.

Conclusion

In conclusion, assessing the impact of mechanical shocks on lens optical properties is a critical aspect of product development that can significantly impact business success. Eurolabs laboratory service offers a comprehensive solution to this problem, providing businesses with accurate simulation of real-world conditions, customized testing solutions, and expert analysis of data.

By investing in Impact of Mechanical Shocks on Lens Optical Properties testing, businesses can ensure the reliability, performance, and longevity of their products, ultimately driving growth and customer satisfaction. Contact us today to learn more about how Eurolabs laboratory service can benefit your business.