Test for Optical Distortion After Mechanical Shock

The Crucial Test for Optical Distortion After Mechanical Shock Ensuring Your Products Precision and Reliability

In todays competitive marketplace, manufacturers are constantly seeking ways to improve the quality and reliability of their products. One crucial aspect of product development is ensuring that optical components can withstand mechanical stress without compromising their performance. This is where Test for Optical Distortion After Mechanical Shock comes into play. Provided by Eurolab, this laboratory service is an essential tool for businesses looking to guarantee the precision and reliability of their products.

What is Test for Optical Distortion After Mechanical Shock?

Test for Optical Distortion After Mechanical Shock is a comprehensive laboratory service designed to evaluate the impact of mechanical stress on optical components. This test simulates real-world conditions, exposing the components to various levels of shock and vibration while monitoring their performance in terms of optical distortion. The primary objective of this test is to identify any potential issues that may arise from mechanical stress, enabling manufacturers to take corrective action and prevent costly failures.

Why is Test for Optical Distortion After Mechanical Shock Essential for Businesses?

In todays fast-paced manufacturing environment, the stakes are high, and product reliability is paramount. A single defect or malfunction can result in significant financial losses, damage to a companys reputation, and even harm to end-users. By incorporating Test for Optical Distortion After Mechanical Shock into their quality control processes, businesses can

Ensure Product Reliability Identify potential issues before they reach the market, preventing costly recalls and product failures.

Maintain Brand Integrity Build trust with customers by demonstrating a commitment to quality and reliability.

Reduce Costs Avoid the financial burden of product replacements, repairs, and warranty claims.

Improve Customer Satisfaction Deliver high-quality products that meet or exceed customer expectations.

Key Benefits of Test for Optical Distortion After Mechanical Shock

Our comprehensive laboratory service offers numerous benefits, including

Accurate Results Our state-of-the-art equipment and experienced technicians provide precise measurements and analysis.

Customized Testing We offer tailored testing programs to meet the unique needs of your products and manufacturing processes.

Comprehensive Reporting Detailed reports outline test results, identifying areas for improvement and providing actionable recommendations.

Enhanced Product Development Test for Optical Distortion After Mechanical Shock enables manufacturers to refine their designs, materials, and production methods.

Understanding the Testing Process

At Eurolab, we employ a thorough testing process that involves several key steps

Sample Preparation Carefully selected samples are prepared according to your specifications.

Mechanical Stress Application Samples are subjected to varying levels of mechanical stress, simulating real-world conditions.

Optical Distortion Measurement Our advanced equipment measures and records any changes in optical distortion.

Data Analysis Experienced technicians analyze the results, identifying areas for improvement.

Frequently Asked Questions

At Eurolab, we understand that our clients may have questions about Test for Optical Distortion After Mechanical Shock. Below are some answers to common inquiries

Q What types of products can be tested?

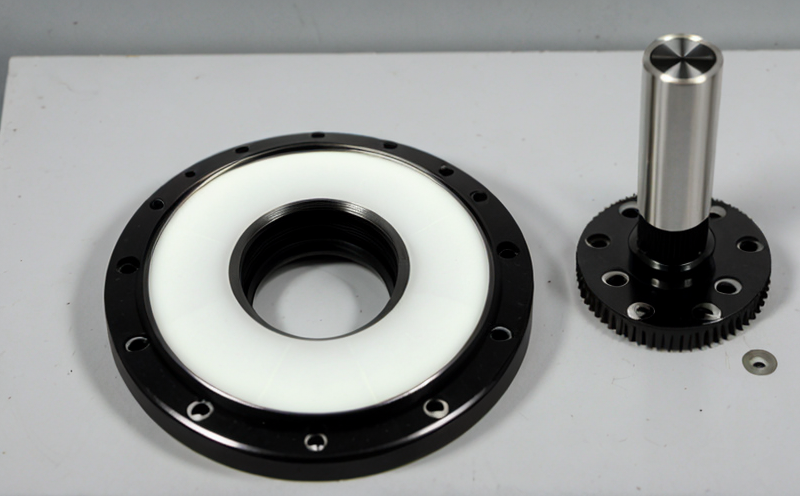

A Our laboratory service is suitable for a wide range of optical components, including lenses, mirrors, and beam splitters.

Q How long does the testing process take?

A Testing times vary depending on the complexity of the test and the number of samples. Our experienced technicians will provide you with a detailed timeline.

Q Can I customize the testing program to meet my specific needs?

A Yes, we offer tailored testing programs to accommodate your unique requirements and manufacturing processes.

Conclusion

In conclusion, Test for Optical Distortion After Mechanical Shock is an essential laboratory service that ensures the precision and reliability of optical components. By incorporating this test into their quality control processes, businesses can guarantee product reliability, maintain brand integrity, reduce costs, and improve customer satisfaction. At Eurolab, our experienced technicians and state-of-the-art equipment provide accurate results, customized testing, comprehensive reporting, and enhanced product development.

Dont risk the reputation of your products or business choose Eurolabs Test for Optical Distortion After Mechanical Shock to ensure precision and reliability in every component.