Mechanical Shock Resistance at Low and High Temperatures

Understanding Mechanical Shock Resistance at Low and High Temperatures A Crucial Laboratory Service for Businesses

In todays fast-paced industrial world, products are subject to a wide range of environmental conditions, from extreme temperatures to mechanical shocks. This can have significant consequences on their performance, reliability, and lifespan. To ensure that your products meet the required standards, it is essential to test them against these stresses. Mechanical Shock Resistance at Low and High Temperatures is a laboratory service offered by Eurolab, designed to simulate real-world conditions and assess how well your product withstands mechanical shocks at various temperature ranges.

Why Mechanical Shock Resistance Matters

Mechanical shock resistance refers to the ability of a material or product to resist damage caused by sudden impacts or vibrations. This is particularly important for products that are exposed to harsh environments, such as electronic devices, automotive components, and aerospace equipment. At Eurolab, we understand the importance of ensuring your products can withstand mechanical shocks at various temperatures.

Advantages of Mechanical Shock Resistance Testing

The following benefits highlight why Mechanical Shock Resistance at Low and High Temperatures is a crucial laboratory service for businesses

Improved Product Reliability By testing your products ability to resist mechanical shocks, you can ensure it will perform consistently in real-world conditions.

Enhanced Durability Our testing services help identify potential weaknesses in your products design or material selection, allowing for improvements to increase its lifespan.

Reduced Risk of Failure Mechanical shock resistance testing helps minimize the risk of product failure due to sudden impacts or vibrations.

Compliance with Industry Standards Our laboratory adheres to international standards, ensuring that our test results are accepted globally.

Cost Savings By identifying potential weaknesses early on, you can avoid costly redesigns and retooling efforts.

Key Benefits of Mechanical Shock Resistance at Low and High Temperatures

Low Temperature Testing We simulate extreme cold temperatures to assess your products performance in cryogenic conditions.

High Temperature Testing Our testing services mimic scorching heat to evaluate your products ability to withstand elevated temperatures.

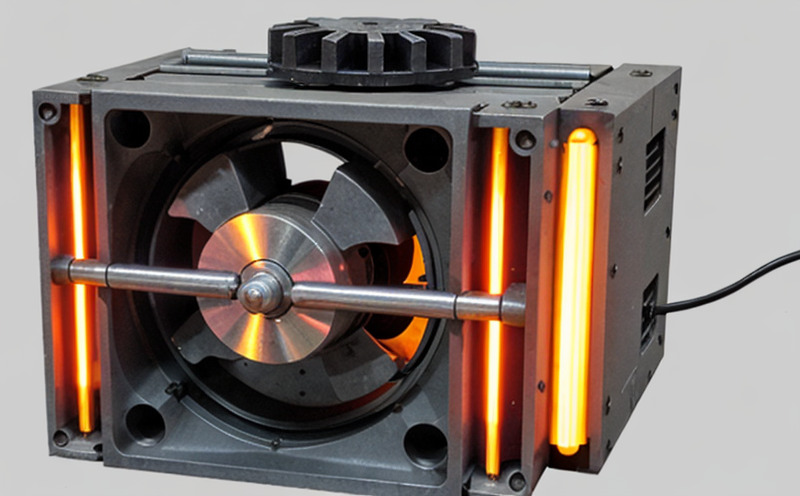

Shake, Vibration, and Impact Resistance Our equipment simulates real-world mechanical shocks to determine the products durability.

Accelerated Life Testing We accelerate the aging process of your product under various temperature conditions to predict its lifespan.

QA Frequently Asked Questions about Mechanical Shock Resistance at Low and High Temperatures

Q What is the purpose of Mechanical Shock Resistance testing?

A This laboratory service tests a products ability to resist mechanical shocks, vibrations, or impacts at low and high temperatures. It helps ensure that your product meets industry standards and can withstand real-world environmental conditions.

Q How does Eurolab conduct Mechanical Shock Resistance testing?

A Our expert technicians use state-of-the-art equipment to simulate various temperature ranges (from -196C to 300C) and mechanical shocks (vibrations, impacts). This helps determine the products durability and reliability in extreme conditions.

Q What are the benefits of accelerated life testing at Eurolab?

A By accelerating the aging process under controlled laboratory conditions, we can predict a products lifespan. This information allows you to make informed decisions about material selection, design improvements, or warranty policies.

Q Can I customize my Mechanical Shock Resistance test program?

A Yes! Our team works closely with clients to develop customized testing programs tailored to specific requirements and industry standards (e.g., military, aerospace, automotive).

Conclusion

In todays competitive marketplace, businesses must ensure that their products meet the highest quality and reliability standards. Eurolabs Mechanical Shock Resistance at Low and High Temperatures laboratory service provides a vital tool for product development teams, allowing them to simulate real-world conditions and identify potential weaknesses before product launch.

By understanding the importance of mechanical shock resistance testing, businesses can

Improve product reliability

Enhance durability

Reduce risk of failure

Comply with industry standards

Save costs

Choose Eurolab as your trusted partner for Mechanical Shock Resistance at Low and High Temperatures. Our team is committed to helping you create high-quality products that meet the demands of your target market.

Eurolab Your Partner in Quality Assurance

At Eurolab, we pride ourselves on delivering exceptional laboratory services tailored to our clients specific needs. With a focus on quality assurance and regulatory compliance, our experts provide reliable results and support for companies worldwide. By collaborating with us, you can ensure that your products meet the highest standards of reliability and performance.

Learn more about Eurolabs Mechanical Shock Resistance at Low and High Temperatures laboratory service today!