Testing for Optical Alignment After Shock Exposure

The Crucial Role of Testing for Optical Alignment After Shock Exposure in Ensuring Product Reliability

In todays fast-paced and highly competitive business landscape, the reliability and performance of products are paramount to success. For companies operating in industries such as optics, photonics, and electronics, ensuring that their components and systems meet precise optical alignment specifications is crucial. This is where Testing for Optical Alignment After Shock Exposure comes into play a laboratory service provided by Eurolab that helps businesses verify the integrity of their products under various environmental conditions.

What is Testing for Optical Alignment After Shock Exposure?

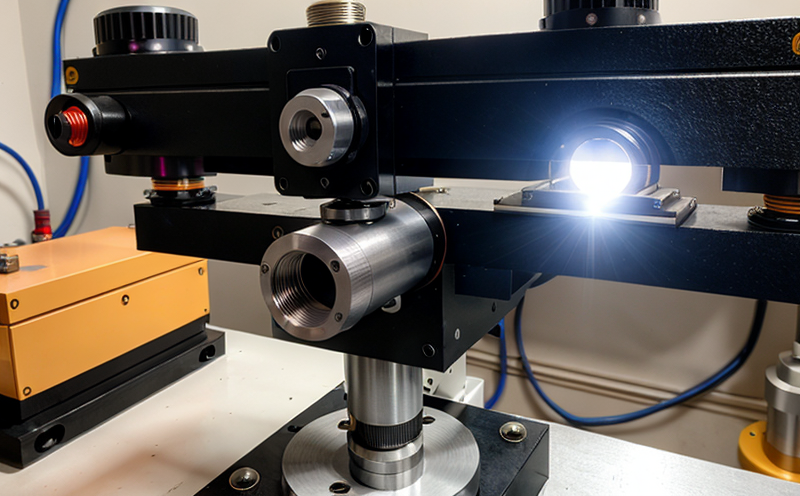

Testing for Optical Alignment After Shock Exposure is a comprehensive evaluation process designed to assess the optical performance of components and systems after they have been subjected to shock exposure. This testing method simulates real-world scenarios, where products are likely to experience physical stress, such as impacts or vibrations, which can cause misalignment or damage to delicate optics.

In essence, this laboratory service helps companies ensure that their products maintain precise optical alignment even after being exposed to harsh environmental conditions, thereby guaranteeing optimal performance and reliability. By leveraging Eurolabs expertise in Testing for Optical Alignment After Shock Exposure, businesses can minimize the risk of product failure, reduce warranty claims, and enhance customer satisfaction.

The Benefits of Using Testing for Optical Alignment After Shock Exposure

Eurolabs Testing for Optical Alignment After Shock Exposure offers a range of benefits that can significantly improve product reliability and performance. Some of the key advantages include

Ensures Optimal Performance By verifying the optical alignment of components after shock exposure, businesses can ensure that their products operate within precise specifications, thereby maintaining optimal performance.

Minimizes Product Failure Testing for Optical Alignment After Shock Exposure helps identify potential issues before they become major problems, reducing the likelihood of product failure and associated costs.

Reduces Warranty Claims By verifying the reliability of components under various environmental conditions, businesses can minimize warranty claims and associated expenses.

Enhances Customer Satisfaction Products that meet precise optical alignment specifications are more likely to deliver consistent performance, resulting in higher customer satisfaction rates.

Meets Industry Standards Eurolabs Testing for Optical Alignment After Shock Exposure is conducted in accordance with industry-recognized standards, ensuring that products meet regulatory requirements and industry expectations.

Key Benefits of Testing for Optical Alignment After Shock Exposure

Here are some key benefits of using Eurolabs laboratory service

Comprehensive Evaluation Our testing process includes a thorough evaluation of optical alignment after shock exposure, providing a complete understanding of product performance.

Real-World Scenario Simulation We simulate real-world scenarios to accurately assess the impact of environmental stressors on product performance.

Expert Analysis Our team of experienced engineers and technicians analyze test results to provide actionable insights and recommendations for improvement.

Flexible Testing Options Eurolab offers a range of testing options, including customized protocols tailored to meet specific business needs.

QA Frequently Asked Questions About Testing for Optical Alignment After Shock Exposure

Weve compiled some frequently asked questions about Testing for Optical Alignment After Shock Exposure to help address common concerns

Q What is the purpose of Testing for Optical Alignment After Shock Exposure?

A The primary goal of this laboratory service is to verify the optical performance of components and systems after they have been subjected to shock exposure, ensuring that products meet precise specifications.

Q How does Eurolabs testing process ensure accurate results?

A Our team of experienced engineers and technicians conduct thorough evaluations using industry-recognized standards and protocols, ensuring accurate and reliable test results.

Q Can I customize the testing protocol to suit my business needs?

A Yes, Eurolab offers flexible testing options, including customized protocols tailored to meet specific business requirements.

Q What types of products benefit from Testing for Optical Alignment After Shock Exposure?

A This laboratory service is particularly relevant for companies operating in industries such as optics, photonics, and electronics, where precise optical alignment is critical.

Conclusion

In conclusion, Eurolabs Testing for Optical Alignment After Shock Exposure plays a crucial role in ensuring product reliability and performance. By leveraging this laboratory service, businesses can minimize the risk of product failure, reduce warranty claims, and enhance customer satisfaction. With our comprehensive evaluation process, real-world scenario simulation, expert analysis, and flexible testing options, Eurolab is the ideal partner for companies seeking to guarantee the integrity of their products under various environmental conditions.

Dont let subpar product performance compromise your businesss reputation and bottom line. Contact us today to learn more about Testing for Optical Alignment After Shock Exposure and discover how Eurolab can help you achieve optimal results.