The Importance of Load Cell Calibration Ensuring Accurate Measurements in Your Industry

In todays fast-paced business environment, accuracy and precision are crucial for success. Whether youre a manufacturer, researcher, or quality control specialist, measuring weights and forces is an essential part of your operations. However, even the slightest margin of error can have significant consequences on product quality, safety, and profitability. This is where Load cell calibration comes in a laboratory service that ensures the accuracy and reliability of your load cells.

At Eurolab, we understand the importance of precise measurements in various industries such as manufacturing, research, and development, quality control, and more. Our expert team provides comprehensive Load cell calibration services to guarantee that your weighing instruments are functioning within specified tolerances. In this article, well delve into the world of Load cell calibration, exploring its benefits, advantages, and significance for businesses like yours.

What is Load Cell Calibration?

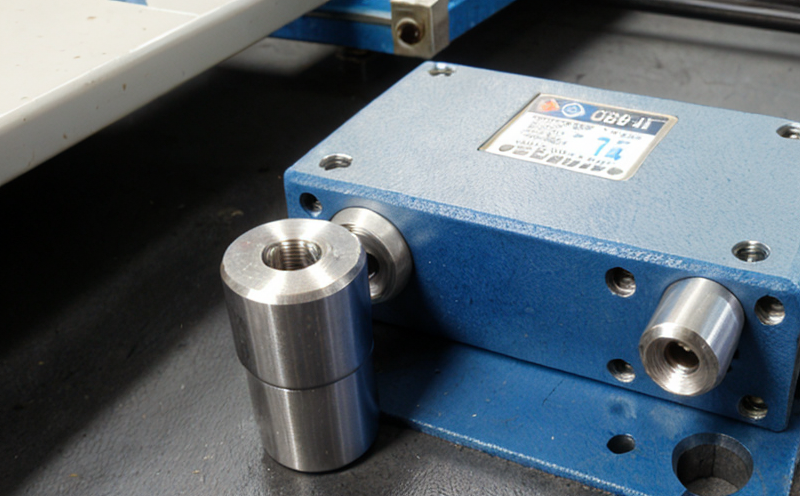

Load cells are transducers that convert a force or weight into an electrical signal. Theyre widely used in various applications, including weighing scales, process control systems, and test equipment. However, over time, load cells can accumulate errors due to wear and tear, environmental factors, or manufacturing defects. This is where calibration comes in the process of adjusting or correcting a devices performance to meet predetermined standards.

Why Load Cell Calibration is Essential for Businesses

Here are just some of the reasons why Load cell calibration is crucial for your industry

Improved Accuracy Regular calibration ensures that your load cells provide precise and reliable measurements, reducing errors and increasing confidence in your results.

Increased Productivity By minimizing downtime and optimizing measurement processes, you can streamline your operations and boost productivity.

Enhanced Quality Control Calibrated load cells help maintain product quality, ensuring compliance with industry standards and regulations.

Cost Savings Avoiding costly recalibrations and reducing the risk of equipment failure saves you time and money in the long run.

Competitive Advantage Demonstrating your commitment to precision measurement can be a differentiator in a crowded market.

The Benefits of Load Cell Calibration

Here are some key benefits of using our Load cell calibration services

Expertise Our experienced technicians have the knowledge and skills to accurately calibrate your load cells, ensuring they meet specified tolerances.

Comprehensive Testing We perform rigorous testing on each load cell to verify its accuracy and reliability.

Customized Solutions We work closely with you to understand your specific calibration needs and provide tailored solutions.

Fast Turnaround Times Our state-of-the-art facilities enable us to deliver calibrated load cells quickly, minimizing downtime for your operations.

ISO/IEC 17025 Accreditation Eurolab is accredited to the ISO/IEC 17025 standard, ensuring our calibration services meet international quality standards.

Common Applications of Load Cells

Load cells are used in a wide range of industries and applications, including

Weighing Scales Load cells are an essential component of weighing scales, providing accurate weight measurements.

Process Control Systems Load cells help control processes by measuring pressure, force, or weight in various industrial settings.

Test Equipment Load cells are used to measure forces and weights in test equipment, ensuring accurate results.

Research and Development Load cells play a crucial role in scientific research, enabling precise measurements of physical quantities.

Frequently Asked Questions

Here are some common questions about Load cell calibration

Q What is the difference between load cell calibration and validation?

A Load cell calibration involves adjusting or correcting a devices performance to meet predetermined standards. Validation is the process of verifying that a calibrated load cell meets specified requirements.

Q How often should I calibrate my load cells?

A The frequency of calibration depends on usage, environmental factors, and industry regulations. Typically, load cells require recalibration every 1-3 years or as recommended by the manufacturer.

Q Can I perform self-calibration on my load cells?

A While its possible to perform simple checks on your load cells, comprehensive calibration requires specialized equipment and expertise. Trusting a professional laboratory like Eurolab ensures accurate results.

Q Will Load cell calibration affect my warranty or certification?

A In most cases, Load cell calibration does not void warranties or certifications. However, consult with your manufacturer or regulatory body to confirm specific requirements.

Conclusion

In todays competitive business landscape, accuracy and precision are no longer luxuries but necessities. At Eurolab, were committed to providing top-notch Load cell calibration services that ensure the reliability and accuracy of your weighing instruments. By choosing our laboratory, youll benefit from expert technicians, comprehensive testing, customized solutions, fast turnaround times, and ISO/IEC 17025 accreditation.

Dont compromise on precision measurement choose Eurolab for Load cell calibration today and experience the difference for yourself.