Load-displacement curve monitoring

Unlocking the Secrets of Materials Load-Displacement Curve Monitoring by Eurolab

In todays fast-paced manufacturing landscape, understanding the mechanical properties of materials is crucial for businesses to stay competitive and ensure product quality. Among various testing methods, load-displacement curve monitoring has emerged as a powerful tool for material characterization. By leveraging this advanced laboratory service, companies can gain valuable insights into their products behavior under different loads, ultimately leading to informed decision-making and improved performance.

At Eurolab, we offer state-of-the-art Load-Displacement Curve Monitoring services that cater to the diverse needs of industries worldwide. Our team of expert technicians and researchers employ cutting-edge equipment and techniques to provide accurate and reliable results. In this article, we will delve into the world of load-displacement curve monitoring, exploring its significance, benefits, and applications.

What is Load-Displacement Curve Monitoring?

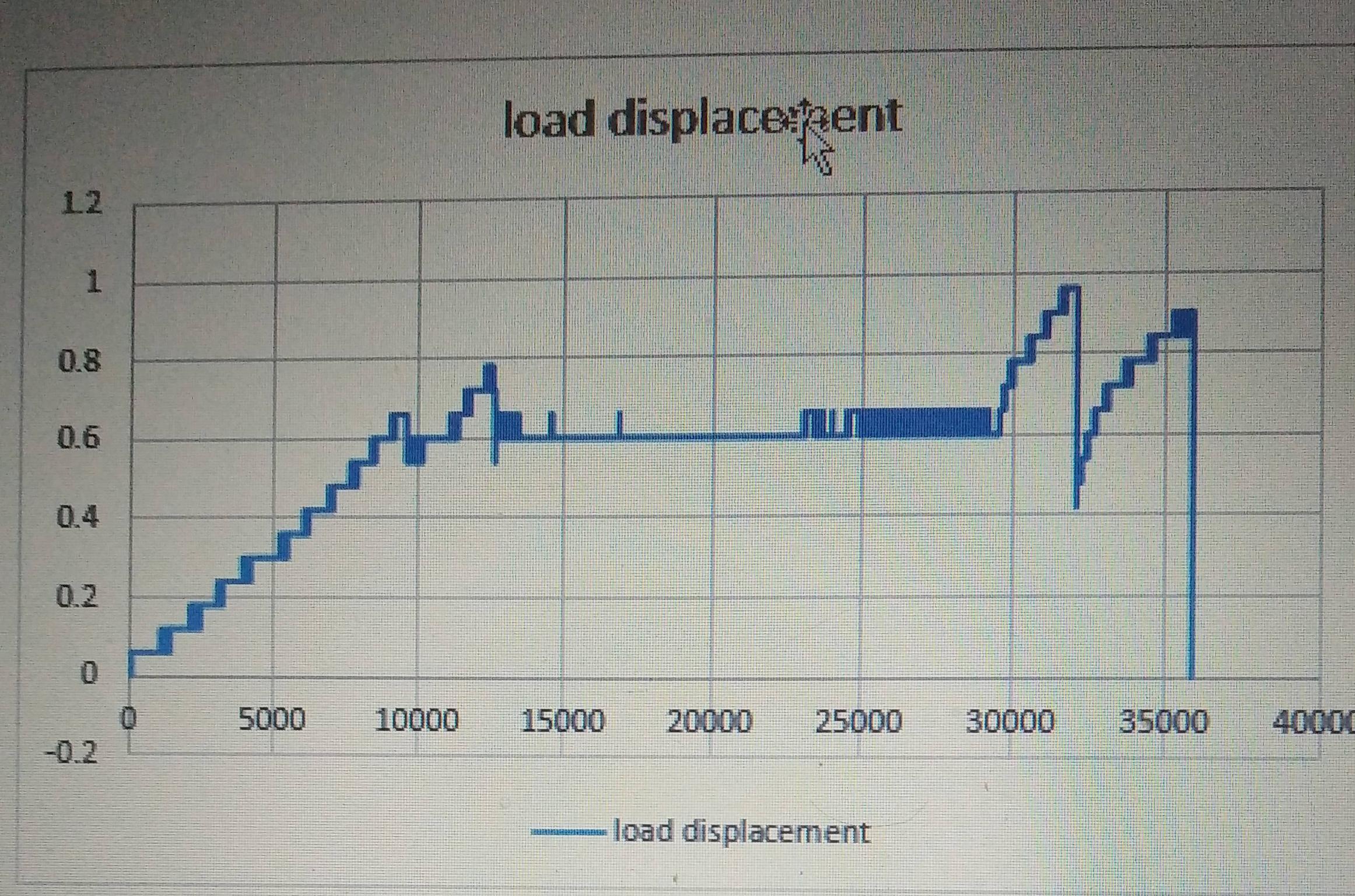

Load-displacement curve monitoring involves applying a controlled load to a material or component while measuring its displacement (or deformation) in real-time. This non-destructive testing method allows for the creation of a comprehensive load-displacement curve, which provides critical information about a materials mechanical properties.

A load-displacement curve is a graphical representation of the relationship between applied load and resulting displacement. By analyzing this curve, researchers can determine various key parameters, including

Elastic modulus A measure of a materials stiffness.

Yield strength The maximum load at which a material begins to deform plastically.

Ultimate tensile strength The maximum stress a material can withstand before failing.

Strain-hardening behavior A materials ability to resist deformation under increasing loads.

These parameters are vital for predicting material behavior in various applications, such as structural components, fasteners, and even biomedical implants.

Why is Load-Displacement Curve Monitoring Essential?

Incorporating load-displacement curve monitoring into your testing regime offers numerous benefits that can significantly impact your business

Improved product design By understanding the mechanical properties of materials, designers can create more efficient and robust products.

Enhanced material selection Load-displacement curve monitoring helps identify suitable materials for specific applications, reducing the risk of premature failure or catastrophic events.

Increased manufacturing efficiency Accurate material characterization enables manufacturers to optimize production processes, reducing waste and energy consumption.

Better understanding of material degradation By analyzing load-displacement curves over time, researchers can identify factors contributing to material deterioration, enabling proactive maintenance strategies.

Key Benefits of Load-Displacement Curve Monitoring

Eurolabs Load-Displacement Curve Monitoring services offer the following advantages

High accuracy and precision Our expert technicians utilize advanced equipment and techniques to ensure reliable results.

Comprehensive data analysis We provide detailed reports, including load-displacement curves, material parameters, and recommendations for improvement.

Customized testing protocols Eurolab adapts our services to meet the unique needs of each client, ensuring that the testing process is efficient and effective.

Rapid turnaround times Our experienced team ensures prompt delivery of results, allowing companies to make informed decisions quickly.

QA Frequently Asked Questions

Weve compiled a list of common questions and answers to provide additional insight into load-displacement curve monitoring

What types of materials can be tested using load-displacement curve monitoring?

Load-displacement curve monitoring is suitable for various materials, including metals (e.g., steel, aluminum), polymers, ceramics, composites, and even biological tissues.

Can this method be used to predict material failure?

Yes, by analyzing the load-displacement curve, researchers can estimate a materials likelihood of failing under specific loads or conditions.

Is load-displacement curve monitoring a non-destructive testing method?

Yes, this technique does not damage the material being tested, making it ideal for materials that are difficult to replace or repair.

How long does the testing process typically take?

The duration of load-displacement curve monitoring depends on the specific application and material properties, but our team ensures prompt delivery of results without compromising accuracy.

Conclusion

In todays competitive market, understanding the mechanical properties of materials is crucial for businesses seeking to improve product quality, reduce costs, and enhance their bottom line. Eurolabs Load-Displacement Curve Monitoring services provide a powerful tool for material characterization, enabling companies to make informed decisions and stay ahead of the curve.

Dont let material uncertainty hold you back partner with Eurolab today to unlock the secrets of your materials and propel your business forward.