Stress-strain curve evaluation

Unlock the Secrets of Your Materials Stress-Strain Curve Evaluation by Eurolab

In todays fast-paced industrial world, materials play a vital role in determining the success or failure of various products and structures. From construction to manufacturing, the properties of materials can make all the difference between safe and durable performance on one hand, and catastrophic failures and costly repairs on the other. One crucial aspect of material evaluation is stress-strain curve evaluation a laboratory service that offers unparalleled insights into the mechanical behavior of your materials.

As a business owner or engineering manager, you understand the importance of ensuring that your products meet rigorous standards of quality and performance. Stress-strain curve evaluation by Eurolab is an essential tool in achieving this goal, providing you with precise data on the elastic and plastic properties of your materials. In this article, well delve into the world of stress-strain curves, exploring the benefits, applications, and importance of this laboratory service.

What is Stress-Strain Curve Evaluation?

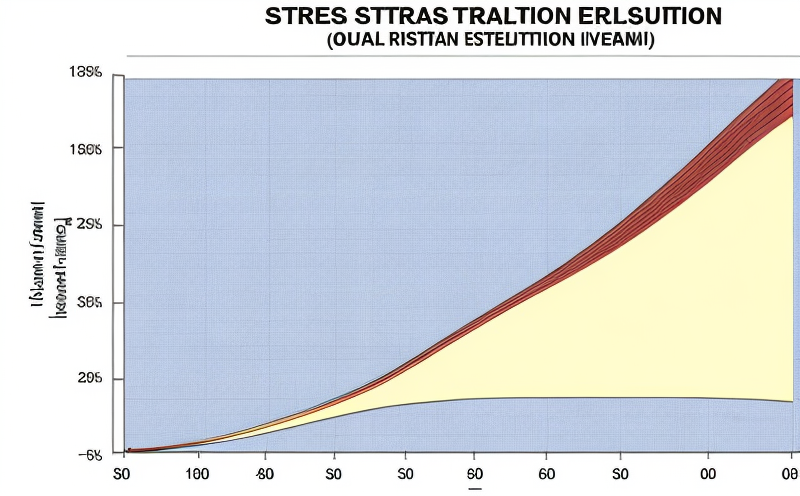

A stress-strain curve is a graphical representation of the relationship between the applied load (stress) and deformation (strain) of a material. This fundamental concept in materials science is used to predict the behavior of materials under various loading conditions, such as tension, compression, or shear. By analyzing the shape and characteristics of the stress-strain curve, engineers can determine critical properties like yield strength, ultimate tensile strength, elongation at break, and modulus of elasticity.

Why Stress-Strain Curve Evaluation Matters

In todays competitive market, businesses need to ensure that their products meet increasingly stringent requirements for safety, performance, and durability. By using stress-strain curve evaluation by Eurolab, you can

Predict Material Behavior Understand how your materials will respond to various loading conditions, enabling informed decisions on material selection and product design.

Improve Product Reliability Identify potential failure points and optimize material properties to reduce the risk of product failures and associated costs.

Enhance Safety Ensure that your products meet regulatory requirements for safety and performance, protecting consumers and reducing liability risks.

Reduce Costs Avoid costly rework or replacement due to material-related issues by selecting materials with optimal properties.

Key Benefits of Stress-Strain Curve Evaluation

Here are the key benefits of using stress-strain curve evaluation

Accurate Material Selection Make informed decisions on material selection based on precise data from stress-strain curves.

Improved Product Design Optimize product design to ensure that materials are used effectively and efficiently.

Enhanced Quality Control Monitor material properties and detect potential issues before they become major problems.

Compliance with Regulations Ensure that your products meet or exceed regulatory requirements for safety, performance, and durability.

Applications of Stress-Strain Curve Evaluation

Stress-strain curve evaluation is a versatile tool with numerous applications across various industries. Some examples include

Construction Materials Evaluate the mechanical properties of concrete, steel, and other building materials to ensure safe and durable construction.

Aerospace Engineering Analyze the stress-strain behavior of advanced materials like composites and alloys for aircraft and spacecraft components.

Automotive Industry Test the mechanical properties of materials used in vehicle manufacturing, such as engine parts, chassis components, and body panels.

Medical Devices Evaluate the biocompatibility and mechanical properties of materials used in medical implants and devices.

QA Frequently Asked Questions

What types of materials can be evaluated using stress-strain curve evaluation?

Eurolabs stress-strain curve evaluation service is suitable for a wide range of materials, including metals (ferrous and non-ferrous), polymers, ceramics, composites, and more.

How do you determine the type of loading condition (tension, compression, or shear)?

Our experienced technicians select the most relevant testing method based on your specific requirements and material properties.

Can I get real-time data during the testing process?

Yes, our state-of-the-art equipment allows for live monitoring and data collection during the testing process.

How long does it take to receive the test results?

We provide rapid turnaround times, typically within a few days or weeks, depending on the complexity of the project.

Conclusion

Stress-strain curve evaluation by Eurolab is an essential tool for businesses seeking to optimize material properties, improve product reliability, and ensure compliance with regulations. By understanding the mechanical behavior of your materials, you can make informed decisions that drive innovation, reduce costs, and enhance safety. Dont compromise on quality choose stress-strain curve evaluation by Eurolab for unparalleled insights into the performance of your materials.

As a leader in laboratory services, Eurolab is committed to providing accurate, reliable, and timely results that meet or exceed your expectations. Whether youre a seasoned engineer or an emerging entrepreneur, we invite you to explore the world of stress-strain curve evaluation and discover how our expertise can help take your business to new heights.

About Eurolab

Eurolab is a trusted provider of laboratory services, offering a comprehensive range of testing and analysis solutions for various industries. Our team of experts combines cutting-edge technology with in-depth knowledge to deliver accurate, reliable, and timely results that meet the highest standards of quality and precision.