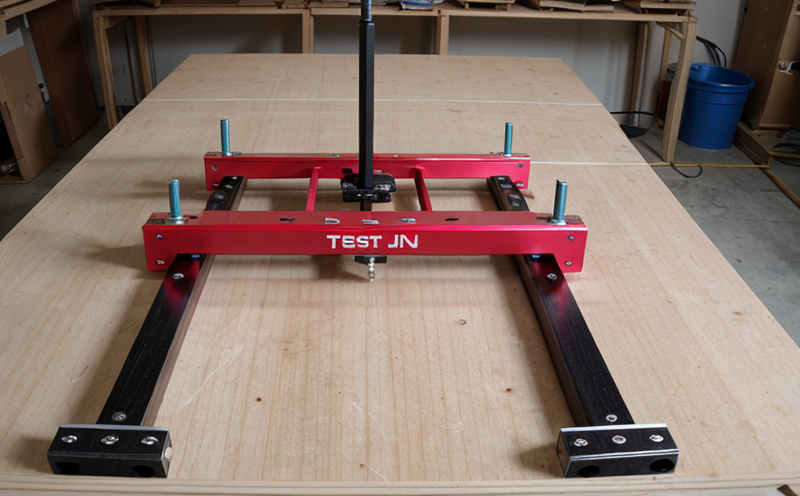

Testing jig configuration

Unlocking Efficient Testing with Eurolabs Expertise The Importance of Testing Jig Configuration

In todays competitive business landscape, ensuring the quality and reliability of products is crucial for manufacturers to maintain customer satisfaction and reputation. One critical aspect of product development is testing, which involves evaluating the performance, safety, and functionality of goods. However, manual testing can be time-consuming, prone to human error, and may not provide accurate results. This is where Eurolabs Testing Jig Configuration service comes in a laboratory-tested solution that optimizes testing efficiency and accuracy.

What is Testing Jig Configuration?

Testing jig configuration refers to the design, development, and implementation of custom-made fixtures or tools used for conducting product tests. These test jigs enable precise measurement and evaluation of products under controlled conditions, ensuring reliable and repeatable results. By configuring a testing jig according to specific requirements, businesses can ensure that their products meet industry standards, regulatory compliance, and desired performance levels.

Why is Testing Jig Configuration Essential for Businesses?

Incorporating testing jig configuration into your product development process offers numerous benefits that contribute to business success

Benefits of Testing Jig Configuration

Improved Accuracy Custom-designed test jigs minimize human error and ensure accurate results, reducing the likelihood of costly rework or product recalls.

Increased Efficiency By automating testing processes, businesses can save time and resources, allowing for faster product development cycles and reduced lead times.

Enhanced Product Quality Testing jig configuration enables precise measurement and evaluation of products, ensuring that they meet industry standards and regulatory requirements.

Reduced Costs Custom-designed test jigs reduce the need for manual testing, minimizing labor costs and the risk of equipment damage or malfunction.

Increased Compliance By configuring testing jigs according to specific requirements, businesses can ensure compliance with industry regulations and standards.

How Eurolabs Testing Jig Configuration Service Works

At Eurolab, our team of experts works closely with clients to develop custom-made test jigs that meet their unique requirements. Our comprehensive service includes

Needs Assessment Our experienced engineers conduct a thorough review of your product and testing needs to determine the most effective configuration for your testing jig.

Design Development We design and develop custom test jigs using advanced software and materials, ensuring optimal performance and durability.

Implementation Our team installs and configures the test jig at your facility or ours, providing training on its operation and maintenance.

Testing and Validation We conduct thorough testing and validation of the product to ensure it meets industry standards and regulatory requirements.

Frequently Asked Questions

Q What types of products can be tested using Eurolabs Testing Jig Configuration service?

A Our service is applicable to a wide range of products, including but not limited to mechanical components, electronic devices, automotive parts, medical equipment, and more.

Q How long does the testing jig configuration process typically take?

A The duration of our testing jig configuration service varies depending on project complexity and scope. However, we can provide a customized timeline for your specific needs.

Q What are the benefits of using Eurolabs Testing Jig Configuration service over in-house development?

A By leveraging our expertise and resources, you can save time and reduce costs associated with developing custom test jigs. Our team ensures that your testing jig is designed and built to meet exacting standards, reducing the risk of errors or rework.

Q Can I purchase a pre-designed testing jig from Eurolab?

A Yes! We offer a range of standard testing jigs for common products, which can be customized to suit specific requirements. Our team will work with you to ensure that your product meets industry standards and regulatory requirements.

Conclusion

Testing jig configuration is a critical component of product development, ensuring the quality, reliability, and performance of goods. At Eurolab, our expert team provides tailored solutions for businesses seeking to optimize testing efficiency, accuracy, and compliance. By choosing our Testing Jig Configuration service, you can

Reduce costs associated with manual testing

Improve product quality and customer satisfaction

Enhance regulatory compliance and industry standards adherence

Dont let inefficient testing hold your business back contact Eurolab today to discuss how our Testing Jig Configuration service can drive success in your industry.