Measuring Component Reliability Under Shock and Vibration

Measuring Component Reliability Under Shock and Vibration The Key to Unlocking Product Durability

In todays fast-paced industrial landscape, the reliability of electronic components is more crucial than ever. As products continue to miniaturize and become increasingly sophisticated, their susceptibility to damage from shock and vibration increases exponentially. A single faulty component can spell disaster for a products overall performance, leading to costly downtime, reduced lifespan, and damaged reputation.

Thats where Eurolab comes in a pioneering laboratory service provider specializing in Measuring Component Reliability Under Shock and Vibration (MCRSV). Our cutting-edge facilities and expert technicians offer an unparalleled level of accuracy and precision in assessing the resilience of electronic components against shock and vibration. By entrusting your products to us, you can ensure that they meet the highest standards of quality and reliability.

The Importance of Measuring Component Reliability Under Shock and Vibration

Measuring Component Reliability Under Shock and Vibration is an essential service for businesses across various industries, including aerospace, automotive, defense, medical devices, and consumer electronics. Here are some compelling reasons why

Improved Product Durability By testing components under shock and vibration, you can identify weaknesses and vulnerabilities that may lead to premature failure or damage.

Reduced Maintenance Costs Regular component inspections can help prevent costly repairs, reduce downtime, and minimize the need for maintenance.

Enhanced Safety Assessing component reliability is critical in industries where products are used in hazardous environments or by vulnerable populations (e.g., aerospace, medical devices).

Compliance with Industry Standards Many regulatory bodies require manufacturers to test their components against shock and vibration. Our laboratory services ensure that your products meet these stringent standards.

Increased Customer Satisfaction By guaranteeing the reliability of your components, you can build trust with customers, enhance brand reputation, and foster long-term relationships.

Key Benefits of Eurolabs Measuring Component Reliability Under Shock and Vibration Service

Eurolabs MCRSV service offers numerous benefits that set us apart from other laboratory providers. Here are some key advantages

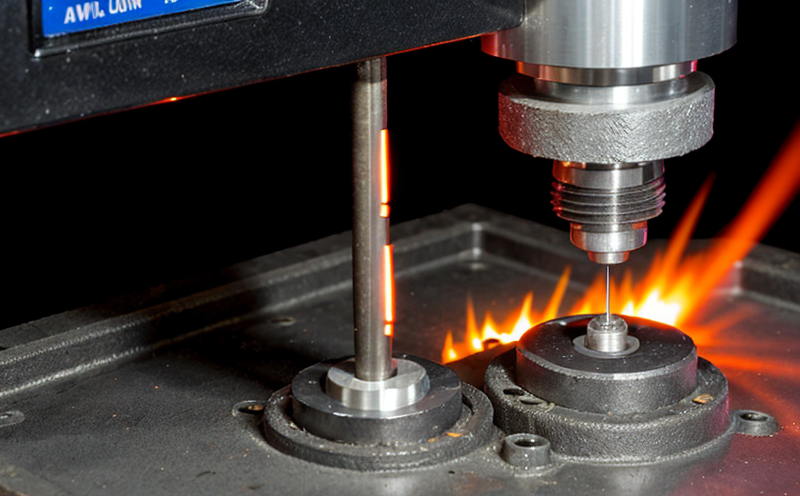

State-of-the-Art Facilities Our laboratories are equipped with the latest generation of shock and vibration testing equipment, ensuring accurate and reliable results.

Expert Technicians Our team of experienced technicians is well-versed in various industry-specific testing protocols and standards.

Customized Testing Plans We work closely with clients to create tailored testing plans that meet specific product requirements and regulatory needs.

Rapid Turnaround Times Our efficient laboratory processes ensure prompt delivery of results, minimizing production delays and optimizing supply chain management.

Comprehensive Reporting We provide detailed reports outlining test procedures, results, and recommendations for improvement.

Frequently Asked Questions (FAQs)

Weve compiled a list of frequently asked questions to address common concerns about Measuring Component Reliability Under Shock and Vibration

Q What is the purpose of measuring component reliability under shock and vibration?

A The primary goal is to assess the resilience of electronic components against damage from mechanical stress, ensuring products meet industry standards for quality and durability.

Q Which industries benefit most from MCRSV services?

A Aerospace, automotive, defense, medical devices, consumer electronics, and other sectors where reliability is critical to product performance and safety.

Q What types of components can be tested using Eurolabs MCRSV service?

A We test a wide range of electronic components, including but not limited to PCBs, connectors, capacitors, inductors, resistors, and ICs.

Q How long does the testing process typically take?

A Turnaround times vary depending on the scope of testing, but our efficient laboratory processes ensure prompt delivery of results.

Q Do I need to provide any specific documentation or information for MCRSV services?

A Yes, we require detailed product specifications, testing protocols, and relevant regulatory requirements to tailor our service to your needs.

Conclusion

Measuring Component Reliability Under Shock and Vibration is a crucial aspect of ensuring the long-term performance and safety of electronic products. Eurolabs expertise in this area provides unparalleled support for businesses seeking to optimize component reliability and meet industry standards. By entrusting your products to us, you can rest assured that they will withstand even the most demanding environments. Contact us today to learn more about our comprehensive MCRSV services and discover how we can help take your product development to the next level.