Testing for Acoustic Vibration Sensitivity in Sensitive Devices

Unlock the Secrets of Sensitive Devices Why Testing for Acoustic Vibration Sensitivity is a Game-Changer

In todays fast-paced world of high-tech innovation, businesses are constantly pushing the boundaries of what is possible with sensitive devices. From cutting-edge medical equipment to sophisticated electronics and precision instruments, these devices are the backbone of modern industry. However, their increased complexity and sensitivity make them vulnerable to a host of environmental factors that can compromise their performance and reliability.

One such factor is acoustic vibration sensitivity the susceptibility of devices to damage or malfunction due to exposure to sound waves, vibrations, or other forms of mechanical stress. For businesses reliant on these sensitive devices, a single malfunction can have catastrophic consequences, resulting in lost productivity, revenue, and reputation.

This is where Testing for Acoustic Vibration Sensitivity in Sensitive Devices comes in a specialized laboratory service offered by Eurolab that helps businesses identify and mitigate the risks associated with acoustic vibration sensitivity. In this article, well delve into the world of acoustic vibration sensitivity testing, exploring its importance, benefits, and applications.

The Advantages of Testing for Acoustic Vibration Sensitivity

Eurolabs Testing for Acoustic Vibration Sensitivity in Sensitive Devices offers a range of advantages that make it an essential service for businesses reliant on sensitive equipment. Some of the key benefits include

Reduced Downtime and Increased Productivity By identifying acoustic vibration sensitivity issues early on, businesses can prevent costly downtime and maintain optimal productivity.

Improved Device Reliability Eurolabs testing services help ensure that devices are designed and manufactured to withstand environmental stressors, reducing the risk of malfunction or failure.

Enhanced Customer Satisfaction By guaranteeing device reliability, businesses can build trust with their customers, who will be more confident in the performance and longevity of sensitive equipment.

Compliance with Industry Regulations Many industries have strict regulations regarding device testing and certification. Eurolabs acoustic vibration sensitivity testing ensures that devices meet or exceed these standards.

Cost Savings Identifying and addressing acoustic vibration sensitivity issues before they cause damage can save businesses a significant amount of money in repair, replacement, or loss of revenue.

What is Acoustic Vibration Sensitivity Testing?

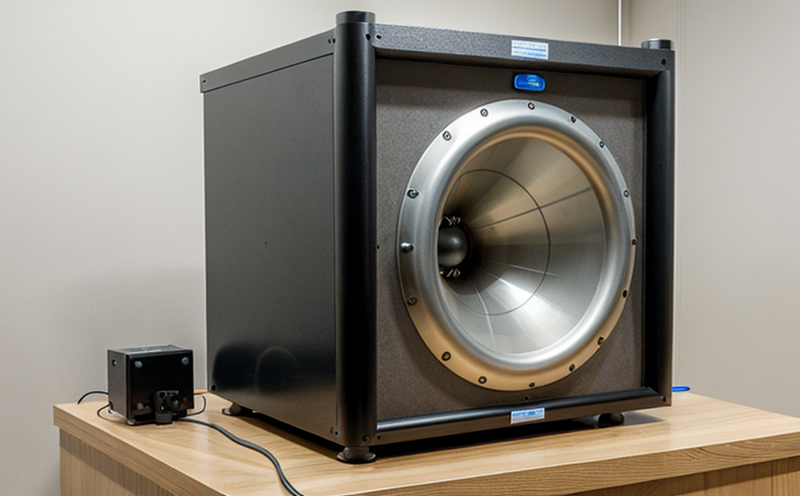

Acoustic vibration sensitivity testing involves subjecting sensitive devices to controlled exposure to sound waves, vibrations, or other forms of mechanical stress. This allows Eurolabs expert technicians to assess the devices response and determine its level of acoustic vibration sensitivity.

During the testing process, devices are typically exposed to a range of frequencies, amplitudes, and durations designed to simulate real-world environmental conditions. The results are then analyzed using sophisticated software and equipment to identify potential issues or areas for improvement.

The Testing Process A Step-by-Step Guide

Eurolabs acoustic vibration sensitivity testing process involves several key steps

Device Preparation Devices are carefully prepared for testing, including cleaning, calibration, and setup.

Test Design Eurolabs expert technicians design a customized test plan to simulate real-world environmental conditions and assess the devices response.

Testing Devices are exposed to controlled sound waves, vibrations, or other forms of mechanical stress.

Data Analysis Results are analyzed using sophisticated software and equipment to identify potential issues or areas for improvement.

Reporting and Recommendations Eurolab provides a comprehensive report detailing the testing results, highlighting areas of sensitivity and recommending mitigation strategies.

Common Applications for Acoustic Vibration Sensitivity Testing

Eurolabs acoustic vibration sensitivity testing service has numerous applications across various industries, including

Medical Equipment Medical devices such as MRI machines, ultrasound equipment, and ventilators require precise control over environmental conditions to ensure patient safety.

Electronics and Semiconductors Electronic components and semiconductor devices are highly susceptible to damage from mechanical stress and require careful testing to ensure reliability.

Precision Instruments Precision instruments, including microscopes, telescopes, and spectrometers, demand extremely high levels of stability and accuracy.

Aerospace and Defense Sensitive equipment used in the aerospace and defense industries requires rigorous testing to meet stringent safety and performance standards.

Frequently Asked Questions (FAQs)

Weve compiled a list of frequently asked questions about Eurolabs Testing for Acoustic Vibration Sensitivity in Sensitive Devices. If you have any further queries or concerns, please dont hesitate to contact us

Q What is acoustic vibration sensitivity?

A Acoustic vibration sensitivity refers to the susceptibility of devices to damage or malfunction due to exposure to sound waves, vibrations, or other forms of mechanical stress.

Q Why is Testing for Acoustic Vibration Sensitivity important?

A Identifying and mitigating acoustic vibration sensitivity issues helps prevent costly downtime, ensure device reliability, and maintain customer satisfaction.

Q What types of devices benefit from acoustic vibration sensitivity testing?

A Sensitive devices across various industries, including medical equipment, electronics, precision instruments, and aerospace/defense applications.

Q How is the testing process designed to simulate real-world environmental conditions?

A Eurolabs expert technicians design customized test plans using sophisticated software and equipment to simulate a range of frequencies, amplitudes, and durations.

Conclusion

In todays fast-paced world of high-tech innovation, businesses rely on sensitive devices to drive productivity, revenue, and growth. However, these devices are vulnerable to environmental factors that can compromise their performance and reliability. Eurolabs Testing for Acoustic Vibration Sensitivity in Sensitive Devices is a specialized laboratory service designed to help businesses identify and mitigate the risks associated with acoustic vibration sensitivity.

By choosing Eurolab, businesses can benefit from reduced downtime, improved device reliability, enhanced customer satisfaction, compliance with industry regulations, and cost savings. With our comprehensive testing services, you can rest assured that your sensitive devices are performing at their best even in the most demanding environments.