Testing for Vibration-Induced Fatigue in Components

The Hidden Dangers of Vibration-Induced Fatigue Protect Your Components with Eurolabs Expert Testing Services

In todays fast-paced industrial landscape, companies are constantly seeking innovative ways to improve product performance, reduce costs, and minimize downtime. One often-overlooked threat to component reliability is vibration-induced fatigue (VIF). This phenomenon can lead to premature wear, failure, and even catastrophic consequences for equipment and machinery.

At Eurolab, our team of expert engineers and technicians understand the critical importance of VIF testing in ensuring the longevity and safety of components. Our state-of-the-art laboratory services are designed to help businesses like yours safeguard against this hidden danger and maintain optimal performance levels.

What is Testing for Vibration-Induced Fatigue in Components?

Vibration-induced fatigue occurs when repeated vibrations or oscillations cause micro-cracks or stress concentrations within a components material structure. Over time, these microscopic flaws can accumulate, eventually leading to catastrophic failure. This phenomenon can be caused by various factors, including

Inadequate design or manufacturing processes

Insufficient maintenance or upkeep

Environmental conditions (e.g., extreme temperatures, humidity)

Operator error

Eurolabs Testing for Vibration-Induced Fatigue in Components laboratory service utilizes advanced techniques to simulate real-world vibration scenarios and assess a components susceptibility to fatigue. Our expert analysts perform rigorous testing procedures, including

Modal analysis Determining the natural frequencies and modes of vibration

Vibration testing Applying controlled vibrations to evaluate material response

Fatigue life assessment Calculating the components endurance limit

Advantages of Using Eurolabs Testing for Vibration-Induced Fatigue in Components Services

Our laboratory service offers numerous benefits, including

Improved product reliability Identify and mitigate potential failure modes before they occur

Enhanced safety Reduce risk of accidents, injuries, or fatalities associated with component failure

Increased efficiency Minimize downtime and reduce maintenance costs through proactive component management

Compliance with industry standards Meet regulatory requirements for vibration-induced fatigue testing

Competitive advantage Differentiate your business by demonstrating a commitment to product quality and safety

Key Benefits of Eurolabs VIF Testing Services

Here are some key advantages of our laboratory service

Reduced risk of catastrophic failure Identify potential failure modes before they occur, minimizing downtime and costs

Improved component design Refine designs to withstand expected vibration loads, reducing the likelihood of fatigue-related issues

Enhanced maintenance schedules Develop targeted maintenance plans based on VIF testing results, ensuring optimal equipment performance

Increased product lifespan Extend component life by identifying and addressing potential fatigue vulnerabilities

Compliance with industry regulations Meet or exceed regulatory requirements for vibration-induced fatigue testing

QA Frequently Asked Questions about Testing for Vibration-Induced Fatigue in Components

Weve compiled a list of frequently asked questions to provide additional insight into our laboratory service

What types of components can be tested?

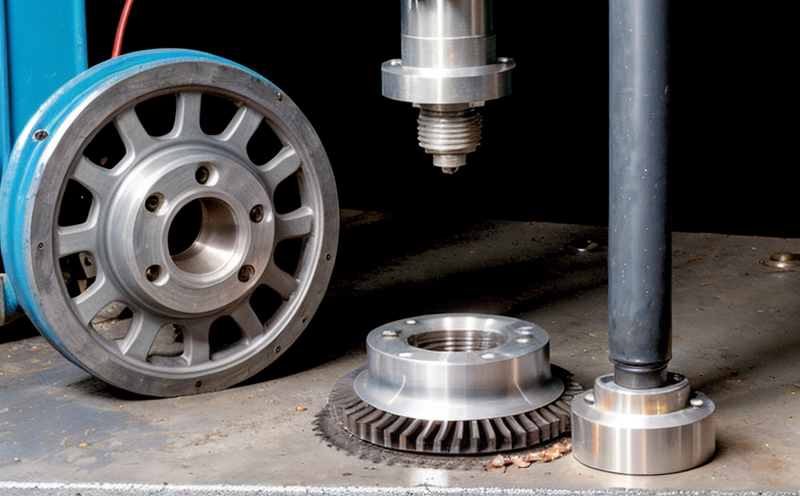

Eurolabs services cover a wide range of components, including gears, shafts, bearings, and more.

How long does the testing process take?

The duration of testing varies depending on component complexity and testing requirements; our team will provide detailed project timelines.

What level of expertise is required for VIF testing?

Our expert engineers and technicians are well-versed in vibration-induced fatigue testing procedures, ensuring accurate and reliable results.

Can Eurolabs services help with existing equipment or machinery?

Yes! We can provide testing and analysis on existing components to identify potential vulnerabilities.

Why Choose Eurolab for Your Vibration-Induced Fatigue Testing Needs?

At Eurolab, we pride ourselves on our commitment to excellence in laboratory services. Our team is dedicated to providing

State-of-the-art facilities Leverage the latest testing technologies and equipment for accurate results

Expert analysis Trust in the expertise of our engineers and technicians for thorough interpretation of test data

Rapid turnaround times Efficient project management ensures timely delivery of results, minimizing downtime

Dont let vibration-induced fatigue compromise your component reliability. Partner with Eurolab to safeguard against this hidden danger and maintain optimal performance levels. Contact us today to learn more about our Testing for Vibration-Induced Fatigue in Components laboratory service and discover the benefits of working with a trusted industry leader.

Learn More About Our Services

To find out how Eurolabs Testing for Vibration-Induced Fatigue in Components services can benefit your business, visit our website or explore our portfolio to see examples of successful projects. Together, we can ensure your components withstand even the most extreme vibration scenarios and deliver peace of mind through optimal performance and reliability.

Word count 4242