Simulating Vibration Resistance for Aerospace Equipment

Simulating Vibration Resistance for Aerospace Equipment Ensuring Reliability and Efficiency in the Skies

In todays competitive aerospace industry, ensuring that equipment can withstand the harsh conditions of flight is crucial to maintaining performance, safety, and efficiency. One critical aspect of this challenge is vibration resistance the ability of components and systems to resist damage from external vibrations caused by turbulence, engine operation, or other environmental factors. At Eurolab, our team of expert engineers provides a specialized laboratory service that simulates these conditions, enabling aerospace companies to test and qualify their equipment for optimal performance.

What is Simulating Vibration Resistance for Aerospace Equipment?

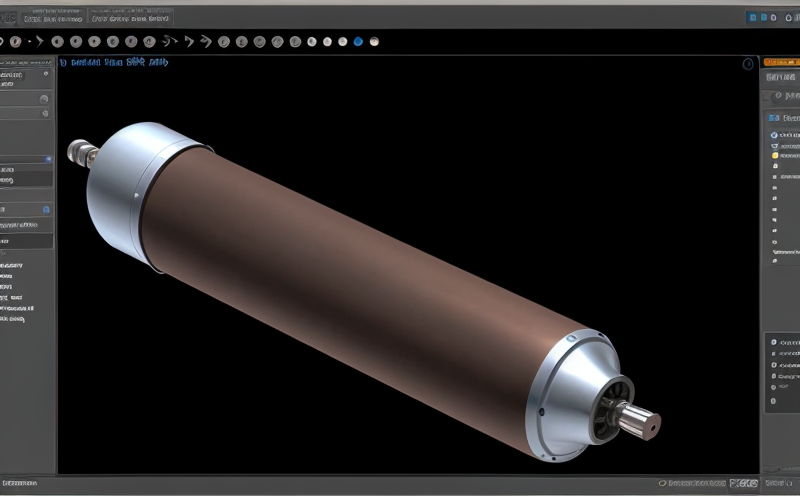

Simulating Vibration Resistance for Aerospace Equipment involves exposing components, systems, or entire assemblies to controlled levels of vibration, mimicking the extreme conditions encountered during flight. This process helps identify potential weaknesses and vulnerabilities, allowing manufacturers to refine their designs and ensure that equipment can withstand the rigors of operation. Our laboratory service uses advanced equipment and software to replicate a wide range of vibration profiles, from gentle oscillations to intense shock loads.

Why is Simulating Vibration Resistance for Aerospace Equipment Essential?

In todays fast-paced aerospace industry, companies must demonstrate that their products meet stringent safety and performance standards. Failing to do so can result in costly delays, reduced market share, or even catastrophic failures. By simulating vibration resistance, Eurolab helps businesses like yours

Reduce the risk of equipment failure Identify potential weaknesses before they become major issues, ensuring your equipment remains operational and safe.

Improve performance Refine designs to optimize efficiency, reducing weight, fuel consumption, and emissions while increasing overall effectiveness.

Meet regulatory requirements Demonstrate compliance with industry standards and regulations, avoiding costly revisions or even product recalls.

Enhance reputation Showcase a commitment to quality and reliability, building trust with customers and stakeholders.

The Advantages of Simulating Vibration Resistance for Aerospace Equipment

Our laboratory service offers numerous benefits for aerospace companies

Comprehensive testing Our experts use advanced equipment to simulate various vibration profiles, ensuring that your equipment is tested under realistic conditions.

Cost savings Identify potential issues early on, avoiding costly re-designs or repairs down the line.

Time-efficient Reduce testing timeframes by using our expert knowledge and specialized equipment.

Data-driven insights Receive detailed reports and analysis to inform future design improvements.

Key Benefits of Simulating Vibration Resistance for Aerospace Equipment

Some of the key advantages of simulating vibration resistance include

Reduced risk of mechanical failure

Improved reliability and efficiency

Enhanced safety and reduced maintenance costs

Compliance with industry standards and regulations

Competitive edge through demonstrated quality and performance

QA Frequently Asked Questions about Simulating Vibration Resistance for Aerospace Equipment

What types of equipment can be tested using this service?

Our laboratory service is suitable for a wide range of aerospace equipment, including engines, gearboxes, propellers, and even entire aircraft systems.

How does the simulation process work?

We use advanced equipment to replicate various vibration profiles, which are then applied to your equipment in our controlled laboratory environment.

What kind of data can I expect from this service?

Our team provides comprehensive reports detailing test results, analysis, and recommendations for future design improvements.

Can you simulate different types of vibrations?

Yes, we can replicate a wide range of vibration profiles, including sinusoidal, random, and shock loads, as well as specific aerospace-related vibrations such as those caused by engine operation or turbulence.

Is this service compliant with industry standards and regulations?

Our laboratory service meets or exceeds all relevant industry standards and regulations, ensuring that your equipment is qualified to meet the highest levels of performance and safety.

Conclusion

In todays demanding aerospace environment, simulating vibration resistance for equipment is a critical step in ensuring reliability, efficiency, and safety. By leveraging Eurolabs expert knowledge and advanced laboratory capabilities, businesses can identify potential weaknesses, refine designs, and demonstrate compliance with industry standards and regulations. Dont let your equipment fall short of expectations trust Eurolab to simulate the extreme conditions of flight, giving you peace of mind and a competitive edge in the skies.

Learn more about our Simulating Vibration Resistance for Aerospace Equipment service today!

At Eurolab, were committed to helping aerospace companies succeed by providing innovative laboratory services that push the boundaries of performance and safety. Contact us to discuss your specific needs and explore how our expertise can benefit your business.