Methods for tensile strength testing of aerospace materials

The Crucial Role of Tensile Strength Testing in Aerospace Materials Why Eurolabs Expertise Matters

In the high-stakes world of aerospace engineering, materials play a critical role in ensuring the safety and performance of aircraft, spacecraft, and other aerial vehicles. Among these materials, tensile strength testing is an essential laboratory service that helps businesses and manufacturers verify the integrity and reliability of their products. As a leading provider of laboratory services, Eurolab offers expert tensile strength testing for aerospace materials, helping clients make informed decisions about their product development and certification processes.

What is Tensile Strength Testing?

Tensile strength testing measures the maximum stress a material can withstand while being stretched or pulled before failing or breaking. This fundamental property of materials is crucial in predicting how they will perform under various loads and stresses, such as flight conditions, temperature fluctuations, and other environmental factors.

In aerospace engineering, tensile strength testing is particularly important because it affects not only the structural integrity but also the overall performance and efficiency of aircraft and spacecraft. Materials with high tensile strength can withstand greater stresses, reducing the risk of catastrophic failures and ensuring safe operation.

The Importance of Tensile Strength Testing in Aerospace Materials

Eurolabs tensile strength testing services are designed to provide accurate and reliable results for a wide range of aerospace materials, including metals, alloys, composites, and polymers. The benefits of using this service are numerous

Ensures Material Safety By verifying the tensile strength of aerospace materials, manufacturers can identify potential weaknesses and vulnerabilities, reducing the risk of material failure and associated safety risks.

Optimizes Product Performance Tensile strength testing helps engineers select the most suitable materials for specific applications, ensuring that products meet performance requirements and operate within design specifications.

Supports Regulatory Compliance Eurolabs tensile strength testing services help clients comply with industry standards and regulations, such as those set by ASTM (American Society for Testing and Materials), API (American Petroleum Institute), and other governing bodies.

Reduces Costs By identifying material weaknesses early on, manufacturers can avoid costly re-designs, re-work, or even catastrophic failures that can lead to significant financial losses.

Key Benefits of Eurolabs Tensile Strength Testing Services

Here are some key benefits of using Eurolabs tensile strength testing services for aerospace materials

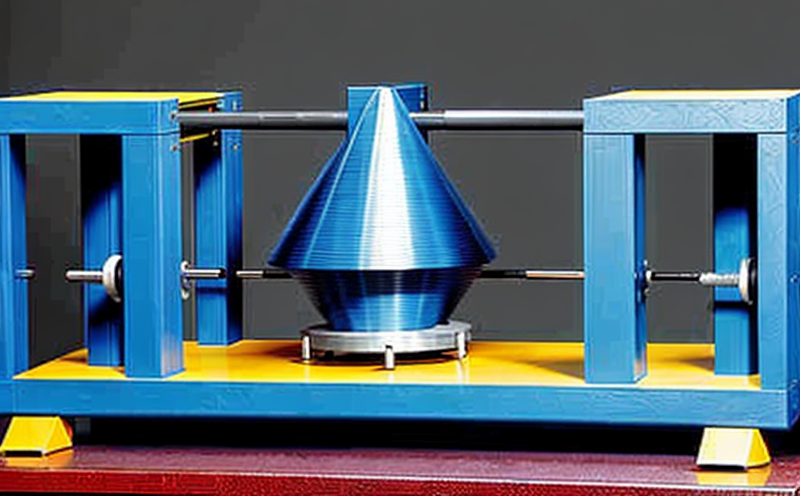

Comprehensive Testing Capabilities Eurolab offers a wide range of tensile testing equipment and techniques, including universal testing machines (UTMs), servo-hydraulic testers, and electronic control systems.

State-of-the-Art Facilities Our laboratory is equipped with modern facilities, including climate-controlled chambers, humidity control systems, and advanced data acquisition software.

Expert Analysis and Reporting Eurolabs experienced engineers provide thorough analysis and reporting of test results, helping clients understand the implications of their findings and make informed decisions about material selection and product development.

Quick Turnaround Times We offer fast turnaround times for testing and reporting, ensuring that our clients can stay on schedule with their projects.

QA Frequently Asked Questions About Tensile Strength Testing

Here are some frequently asked questions about tensile strength testing, along with answers from Eurolabs experts

Q What types of materials can be tested using Eurolabs tensile strength testing services?

A We test a wide range of aerospace materials, including metals (e.g., aluminum, titanium), alloys, composites (e.g., carbon fiber reinforced polymers), and polymers.

Q How do you ensure the accuracy and reliability of your tensile strength testing results?

A Our laboratory follows strict quality control procedures, using calibrated equipment and maintaining a clean and controlled environment to minimize errors and variability.

Q Can I request customized testing protocols or specific testing conditions for my materials?

A Yes, our experienced engineers work closely with clients to develop tailored testing plans that meet their unique requirements and specifications.

Conclusion

Tensile strength testing is an essential laboratory service in aerospace engineering, helping manufacturers ensure the safety, performance, and reliability of their products. As a leading provider of tensile strength testing services, Eurolab offers expert analysis, state-of-the-art facilities, and quick turnaround times to support clients in making informed decisions about material selection and product development.

Whether youre an aerospace engineer, materials scientist, or project manager, Eurolabs tensile strength testing services can help you meet your goals and achieve success in the competitive world of aerospace engineering. Contact us today to learn more about how our expert laboratory services can support your business needs.

Note All rights reserved by Eurolab. This article may be reproduced with permission only, subject to full attribution and link back to the original source.