Tensile strength testing for aerospace fasteners and joining components

The Crucial Role of Tensile Strength Testing for Aerospace Fasteners and Joining Components

In the fast-paced world of aerospace manufacturing, the reliability and safety of components are paramount. One critical aspect that ensures the integrity of aerospace fasteners and joining components is tensile strength testing. This laboratory service, provided by Eurolab, plays a vital role in verifying the mechanical properties of materials used in aerospace applications.

What is Tensile Strength Testing for Aerospace Fasteners and Joining Components?

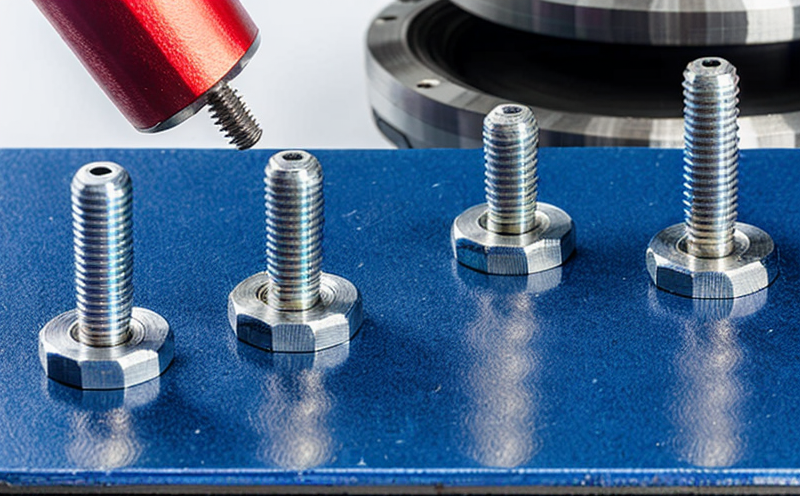

Tensile strength testing involves applying a controlled force to a material or component until it breaks, measuring the amount of stress required to cause failure. This laboratory service helps manufacturers determine the tensile strength of aerospace fasteners and joining components, such as bolts, nuts, screws, and other connectors. By simulating real-world conditions, Eurolabs experts ensure that these critical components can withstand the stresses of flight, turbulence, and environmental factors.

Why is Tensile Strength Testing Essential for Aerospace Fasteners and Joining Components?

The aerospace industry demands high-performance materials with exceptional strength-to-weight ratios. Inadequate material properties can lead to catastrophic failures, resulting in costly repairs, reputational damage, and even safety risks. Eurolabs tensile strength testing service helps businesses

Ensure Compliance Meet regulatory requirements for aerospace materials, such as those outlined by AS 9100 and NASM-

Validate Material Properties Verify the mechanical properties of fasteners and joining components to ensure they meet design specifications.

Reduce Risk Minimize the likelihood of material failure, which can lead to costly downtime, damage, or even loss of life.

Improve Efficiency Streamline manufacturing processes by identifying potential issues early on and eliminating the need for rework or replacement.

Enhance Customer Satisfaction Deliver high-quality products that meet customer expectations, reducing the risk of product returns and reputational damage.

Key Benefits of Tensile Strength Testing for Aerospace Fasteners and Joining Components

Improved Material Selection Eurolabs expert analysis helps you choose the most suitable materials for your aerospace applications.

Enhanced Quality Control Regular tensile strength testing ensures that your fasteners and joining components meet or exceed design specifications.

Increased Reliability By verifying material properties, you can trust that your products will perform consistently in demanding environments.

Reduced Costs Identify potential issues early on to avoid costly rework, replacement, or repairs.

Compliance with Industry Standards Meet regulatory requirements for aerospace materials and maintain a competitive edge.

Frequently Asked Questions (FAQs)

Q What types of materials can Eurolab test?

A We specialize in testing a wide range of materials used in aerospace applications, including metals, alloys, composites, and more.

Q How do I prepare my samples for testing?

A Our experienced team will guide you through the sample preparation process to ensure that your materials are properly prepared for testing.

Q What kind of equipment does Eurolab use for tensile strength testing?

A We utilize state-of-the-art equipment, including high-precision machines and software, to ensure accurate and reliable results.

Q How long does a typical test take?

A The duration of a test can vary depending on the material and the specific requirements of your project. Our team will work with you to determine the best testing schedule for your needs.

Q Can Eurolab provide custom testing programs tailored to my business needs?

A Yes, we offer bespoke testing services designed to meet the unique requirements of your aerospace fasteners and joining components.

Conclusion

In the demanding world of aerospace manufacturing, tensile strength testing is a critical component of ensuring product reliability and safety. By partnering with Eurolab for this laboratory service, businesses can rest assured that their fasteners and joining components are verified to meet or exceed industry standards. With our expertise and state-of-the-art equipment, you can

Ensure compliance with regulatory requirements

Validate material properties for high-performance applications

Reduce the risk of material failure

Improve efficiency in manufacturing processes

Enhance customer satisfaction through delivering high-quality products

Choose Eurolab as your trusted partner for tensile strength testing and take the first step towards achieving unparalleled product reliability and safety in the aerospace industry.