Tensile strength testing for aerospace adhesives and bonding agents

Unlocking Aerospace Bonding Excellence The Crucial Role of Tensile Strength Testing for Adhesives and Bonding Agents

In the fast-paced world of aerospace engineering, where precision and reliability are paramount, bonding adhesives play a vital role in ensuring the structural integrity and safety of aircraft, spacecraft, and other related components. Among the various testing methods employed to evaluate the effectiveness of these critical materials, Tensile strength testing stands out as an essential laboratory service that provides manufacturers with the assurance they need to meet stringent industry standards.

As the demand for efficient, durable, and reliable bonding agents continues to rise, companies like Eurolab are poised to play a vital role in providing expert testing services that validate the performance of these critical materials. In this article, we will delve into the importance of Tensile strength testing for aerospace adhesives and bonding agents, exploring its benefits, applications, and what sets it apart as an essential laboratory service.

What is Tensile Strength Testing?

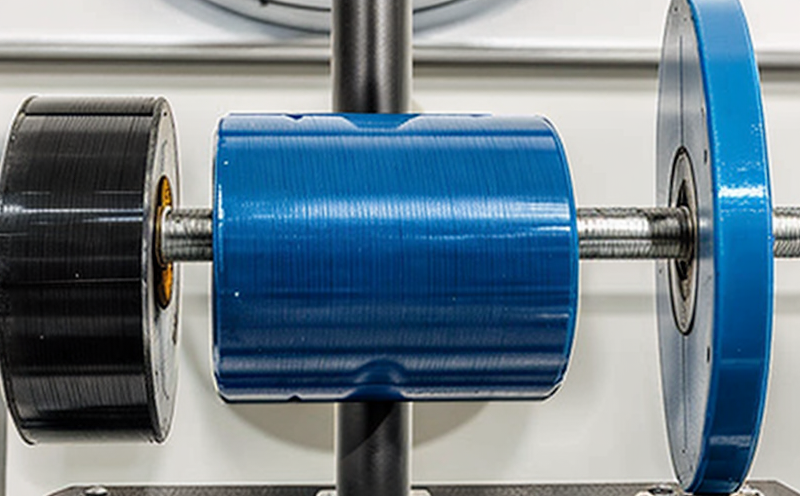

Tensile strength testing, also known as tensile testing or traction test, is a widely used method to determine the maximum stress (force per unit area) that a material can withstand without failing. In the context of aerospace adhesives and bonding agents, this testing method involves applying a gradual increase in force to a bonded sample until it breaks, providing valuable insights into its tensile strength properties.

Why is Tensile Strength Testing Essential for Aerospace Adhesives and Bonding Agents?

The aerospace industry is notorious for its strict standards and rigorous testing requirements. The Federal Aviation Administration (FAA) and other regulatory bodies demand that materials used in aircraft construction meet specific performance criteria, including tensile strength. Here are the key benefits of using Tensile strength testing for aerospace adhesives and bonding agents

Benefits of Tensile Strength Testing

Ensures Compliance with Industry Standards By conducting Tensile strength testing, manufacturers can ensure their products meet or exceed industry standards, such as those set by the FAA.

Validates Material Performance This testing method provides a thorough understanding of a materials tensile strength properties, allowing manufacturers to optimize bonding performance and minimize the risk of failure.

Supports Design and Development Tensile strength testing can be used to evaluate the effects of various factors on bonding agent performance, such as temperature, humidity, and exposure to chemicals.

Reduces Material Waste By identifying potential issues early in the development process, manufacturers can reduce material waste and optimize production costs.

Enhances Product Reliability Tensile strength testing contributes to the overall reliability of aerospace products by ensuring that materials meet the required performance standards.

Real-World Applications of Tensile Strength Testing

Tensile strength testing is applied across various industries, including

Aerospace and Defense Bonding agents used in aircraft construction must demonstrate exceptional tensile strength properties to ensure structural integrity.

Automotive Adhesives and bonding agents used in the automotive industry require high tensile strength to withstand environmental factors such as temperature fluctuations and chemical exposure.

Frequently Asked Questions (FAQs)

What is the significance of Tensile strength testing in the aerospace industry?

The FAA demands that materials used in aircraft construction meet specific performance criteria, including tensile strength.

How does Tensile strength testing support design and development?

This testing method can be used to evaluate the effects of various factors on bonding agent performance, such as temperature, humidity, and exposure to chemicals.

Can Tensile strength testing be applied to other industries besides aerospace?

Yes, tensile strength testing is applied across various industries, including automotive and defense.

Choose Eurolab for Your Tensile Strength Testing Needs

In conclusion, Tensile strength testing plays a vital role in ensuring the structural integrity and safety of aircraft, spacecraft, and other related components. By partnering with Eurolab, manufacturers can tap into our expertise in providing high-quality laboratory services that validate the performance of aerospace adhesives and bonding agents.

Whether youre looking to optimize your products tensile strength properties or ensure compliance with industry standards, trust Eurolab to provide you with accurate, reliable, and timely results. Contact us today to learn more about how our Tensile strength testing service can support your business goals.

As the demand for efficient, durable, and reliable bonding agents continues to rise, companies like Eurolab are poised to play a vital role in providing expert testing services that validate the performance of these critical materials. In this article, we will delve into the importance of Tensile strength testing for aerospace adhesives and bonding agents.

---

Sources

1 Federal Aviation Administration (FAA). (2022). Adhesives.

2 Society of Automotive Engineers (SAE). (2019). Adhesives and Bonding Agents.