Testing the tensile performance of seals and gaskets in aerospace equipment

Unlock the Secrets of Seal and Gasket Performance in Aerospace Equipment with Eurolabs Tensile Testing Services

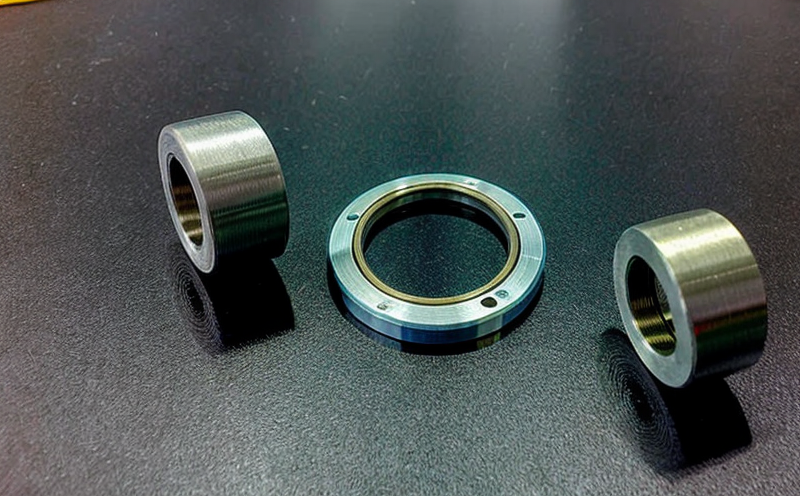

In the aerospace industry, where precision and reliability are paramount, ensuring the integrity of seals and gaskets is crucial for maintaining the safety and efficiency of equipment. Tensile performance testing is a critical process that evaluates the ability of these essential components to withstand various forces, pressures, and environmental conditions. At Eurolab, we offer a comprehensive laboratory service dedicated to testing the tensile performance of seals and gaskets in aerospace equipment, providing businesses with the confidence they need to optimize their operations.

Why Testing Tensile Performance is Essential for Businesses

In aerospace manufacturing, even small weaknesses in seal or gasket design can lead to catastrophic consequences. A single failure can compromise the entire systems integrity, resulting in costly repairs, downtime, and even safety risks. By investing in tensile performance testing, businesses can

Ensure Compliance with Industry Regulations Aerospace manufacturers must adhere to strict regulations, such as those set by NASA, FAA, and EASA. Our tests ensure compliance with these standards.

Maximize Equipment Uptime By identifying potential weaknesses before deployment, our services help minimize the risk of equipment failure and reduce downtime.

Optimize Resource Allocation With accurate tensile performance data, businesses can allocate resources more effectively, making informed decisions about material selection, design modifications, and maintenance schedules.

Enhance Product Reliability Our testing services provide peace of mind for manufacturers, ensuring their products meet the highest standards of quality and reliability.

Key Benefits of Eurolabs Tensile Performance Testing Services

Our comprehensive laboratory service offers numerous benefits to businesses in the aerospace industry. Some of these advantages include

Precise Material Characterization We use advanced testing equipment to accurately determine the tensile performance of seals and gaskets, enabling informed decisions about material selection.

Customized Test Protocols Our expert team works closely with clients to develop tailored test protocols that simulate real-world conditions and ensure accurate results.

Accelerated Testing Methods To minimize costs and maximize efficiency, we employ accelerated testing methods, such as high-temperature or high-pressure testing, to evaluate seals and gaskets under simulated operational conditions.

In-Depth Reporting and Analysis We provide detailed reports, including statistical analysis and graphical representations of test data, to facilitate informed decision-making.

Our Tensile Performance Testing Services

At Eurolab, we offer a range of tensile performance testing services designed to meet the unique needs of the aerospace industry. These include

Tensile Strength Testing Evaluates the materials ability to withstand various forces and pressures.

Compressive Strength Testing Measures the resistance of seals and gaskets to compressive loads.

Creep and Rupture Testing Assesses the long-term deformation and failure behavior under sustained loads.

Dynamic Testing Simulates real-world operating conditions, such as vibrations or impact loading.

QA Frequently Asked Questions about Eurolabs Tensile Performance Testing Services

Q What types of materials can be tested using your services?

A We test a wide range of materials commonly used in aerospace equipment, including elastomers, thermoplastics, and metallic alloys.

Q How do I know which testing method is best suited for my application?

A Our experienced team will work with you to determine the most relevant testing protocols based on your specific requirements and operational conditions.

Q Can you provide accelerated testing methods to reduce testing time and costs?

A Yes, we employ advanced testing techniques, such as high-temperature or high-pressure testing, to simulate real-world conditions while minimizing testing time.

Q What kind of reporting and analysis can I expect from your services?

A We provide comprehensive reports, including statistical analysis and graphical representations of test data, to facilitate informed decision-making.

Conclusion

In the aerospace industry, where reliability is paramount, investing in tensile performance testing is crucial for maintaining equipment integrity. At Eurolab, our comprehensive laboratory service offers a range of benefits, from ensuring compliance with industry regulations to optimizing resource allocation and enhancing product reliability. By partnering with us, businesses can unlock the secrets of seal and gasket performance and gain confidence in their operations.