Viscosity analysis during adhesive bonding process

Unlock the Secrets of Adhesive Bonding with Viscosity Analysis

In todays fast-paced manufacturing landscape, adhesive bonding has become an indispensable technology for a wide range of industries, from aerospace and automotive to construction and consumer goods. However, the success of this process heavily relies on one critical factor viscosity analysis. At Eurolab, we understand the importance of accurate viscosity testing in ensuring the reliability and performance of adhesive bonds.

What is Viscosity Analysis during Adhesive Bonding Process?

Viscosity analysis during adhesive bonding process refers to the measurement of a liquids resistance to flow under different conditions. In the context of adhesive bonding, viscosity plays a crucial role in determining the flow behavior and spreadability of adhesives. By analyzing the viscosity of an adhesive, manufacturers can optimize its formulation and application to achieve consistent bond strength, minimize defects, and improve overall product quality.

Why is Viscosity Analysis during Adhesive Bonding Process Essential for Businesses?

Conducting regular viscosity analysis during the adhesive bonding process offers numerous benefits that can significantly impact a companys bottom line. Here are some of the key advantages of using viscosity analysis

Improved Bond Strength By controlling the viscosity of adhesives, manufacturers can ensure consistent bond strength, which is critical in applications where safety and performance are paramount.

Increased Product Reliability Viscosity analysis helps identify potential issues with adhesive flow and spreadability, reducing the likelihood of defects and product failures.

Enhanced Product Performance By optimizing adhesive viscosity, manufacturers can enhance the overall performance of their products, including durability, strength, and resistance to environmental factors.

Reduced Scrap Rates Accurate viscosity testing enables manufacturers to minimize waste and reduce production costs associated with rework and scrap materials.

Compliance with Industry Standards Viscosity analysis ensures that adhesive formulations meet or exceed industry standards for performance, safety, and regulatory compliance.

The Benefits of Using Viscosity Analysis during Adhesive Bonding Process

Here are some key benefits of using viscosity analysis in the adhesive bonding process

Improved Formulation Control Viscosity analysis enables manufacturers to fine-tune their adhesive formulations to achieve optimal flow behavior and spreadability.

Enhanced Quality Control Regular viscosity testing ensures that adhesives meet or exceed performance standards, reducing the risk of defects and product failures.

Increased Efficiency By optimizing adhesive viscosity, manufacturers can streamline production processes, reduce waste, and improve overall productivity.

Better Adhesive Selection Viscosity analysis helps manufacturers select the most suitable adhesive for their specific application, ensuring optimal performance and reliability.

How to Choose the Right Viscosity Analysis Service

With so many laboratory services available, selecting the right one can be a daunting task. Here are some key factors to consider when choosing a viscosity analysis service

Expertise Look for laboratories with extensive experience in adhesive bonding and viscosity analysis.

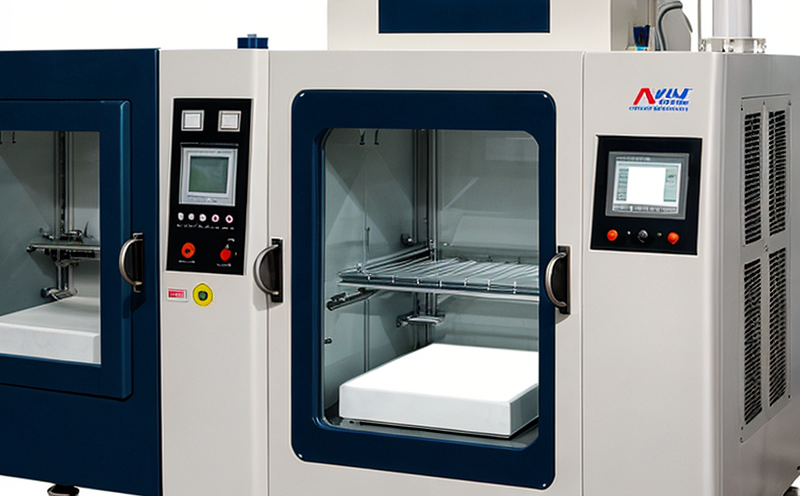

Equipment and Technology Ensure that the laboratory uses state-of-the-art equipment and technology to provide accurate and reliable results.

Quality Control Check if the laboratory has a robust quality control process in place to ensure consistency and accuracy of test results.

QA Frequently Asked Questions about Viscosity Analysis during Adhesive Bonding Process

Here are some frequently asked questions about viscosity analysis during adhesive bonding process

Q What is the importance of viscosity in adhesive bonding?

A Viscosity plays a crucial role in determining the flow behavior and spreadability of adhesives, which directly impacts bond strength and product performance.

Q How often should I conduct viscosity testing on my adhesives?

A Regular viscosity testing (at least quarterly) is recommended to ensure consistent adhesive performance and detect any potential issues before they become major problems.

Q Can I perform viscosity analysis in-house or do I need to send samples to a laboratory?

A While its possible to conduct basic viscosity tests in-house, more advanced testing requires specialized equipment and expertise, which is typically best handled by a reputable laboratory like Eurolab.

Conclusion

Viscosity analysis during adhesive bonding process is an essential tool for manufacturers seeking to improve product performance, reduce defects, and optimize production efficiency. By partnering with Eurolabs experienced team of experts, you can ensure that your adhesives meet or exceed industry standards for viscosity, flow behavior, and spreadability. Dont compromise on the quality and reliability of your products trust Eurolab to provide you with the most accurate and reliable viscosity analysis services in the industry.