Viscosity testing in high-pressure environments

The Critical Importance of Viscosity Testing in High-Pressure Environments Unlocking the Secrets to Your Products Success

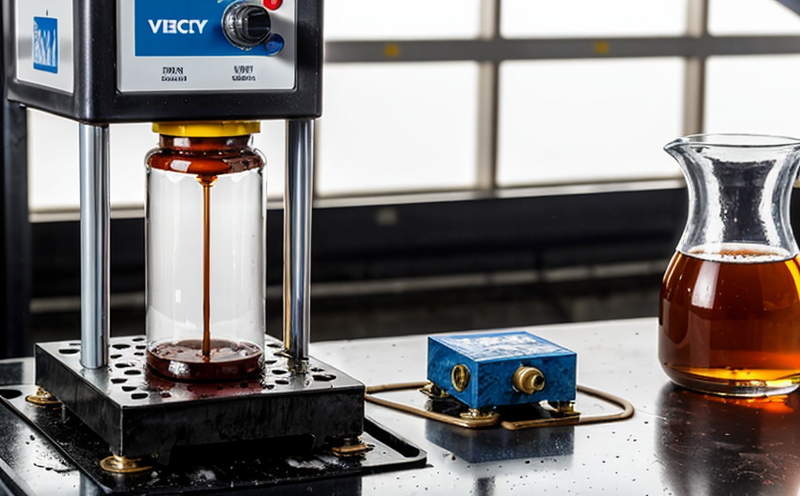

In todays fast-paced industrial world, businesses rely on innovative technologies and meticulous testing procedures to ensure their products meet the highest standards of performance, efficiency, and safety. One crucial laboratory service that plays a vital role in this process is Viscosity testing in high-pressure environments. Conducted by Eurolab, a leading provider of specialized laboratory services, this cutting-edge technique empowers businesses to optimize their products viscosity levels under extreme pressure conditions.

Viscosity testing in high-pressure environments is an essential component of product development and quality control for various industries, including petroleum, chemicals, pharmaceuticals, and automotive. By understanding the dynamic behavior of fluids at high pressures, manufacturers can refine their formulations, improve production efficiency, and guarantee compliance with regulatory standards.

Unlocking the Advantages of Viscosity Testing in High-Pressure Environments

At Eurolab, we understand that viscosity testing is a critical aspect of product development. Our state-of-the-art laboratory facilities are equipped to conduct this specialized service, providing businesses with unparalleled insights into their products behavior under high-pressure conditions. By leveraging the advantages of viscosity testing in high-pressure environments, companies can

Enhance Product Performance Viscosity testing ensures that your products maintain optimal viscosity levels at extreme pressure conditions, guaranteeing consistent performance and efficiency.

Improve Formulation Accuracy Our advanced testing procedures enable manufacturers to precisely determine the ideal formulation for their products, reducing waste and minimizing production costs.

Meet Regulatory Compliance By conducting viscosity testing in high-pressure environments, businesses can ensure compliance with industry-specific regulations and standards, safeguarding against potential recalls or liabilities.

Optimize Production Efficiency With accurate viscosity data, manufacturers can streamline production processes, reduce energy consumption, and lower overall operational expenses.

Key Benefits of Viscosity Testing in High-Pressure Environments

Here are the key benefits of our Viscosity testing in high-pressure environments

Precise Measurements Our advanced equipment ensures accurate measurements of viscosity levels under high-pressure conditions.

Rapid Turnaround Times We offer expedited testing services, enabling businesses to quickly obtain critical data and make informed decisions.

Customized Testing Solutions Eurolabs experienced team works closely with clients to design tailored testing protocols that meet their specific needs and requirements.

Comprehensive Reporting Our detailed reports provide a thorough analysis of test results, including recommendations for improving product performance and efficiency.

Frequently Asked Questions

We understand that some businesses may have questions about viscosity testing in high-pressure environments. Below are some answers to common queries

Q What is the purpose of viscosity testing?

A Viscosity testing measures the fluidity or resistance of a liquid under various conditions, including high pressure. This information helps manufacturers optimize their products performance and efficiency.

Q How does Eurolab conduct viscosity testing in high-pressure environments?

A Our state-of-the-art laboratory facilities are equipped with specialized equipment, such as high-pressure viscometers, to accurately measure viscosity levels at extreme pressure conditions.

Q What types of industries can benefit from viscosity testing in high-pressure environments?

A Various industries, including petroleum, chemicals, pharmaceuticals, and automotive, rely on viscosity testing to ensure compliance with regulatory standards and optimize product performance.

Q Can I customize the testing protocol for my specific needs?

A Yes! Our experienced team works closely with clients to design tailored testing protocols that meet their unique requirements and objectives.

Conclusion

In todays competitive industrial landscape, businesses must prioritize accuracy, efficiency, and safety in their products. Viscosity testing in high-pressure environments is a crucial laboratory service that empowers manufacturers to refine their formulations, improve production processes, and guarantee compliance with regulatory standards. By leveraging the advantages of this specialized service, companies can unlock their full potential, drive innovation, and stay ahead of the curve.

At Eurolab, we are committed to delivering unparalleled testing solutions that meet the evolving needs of businesses across various industries. Trust us to help you navigate the complex world of viscosity testing in high-pressure environments and ensure your products excel under any conditions.