Viscosity measurement during thermal cycling

Unlocking the Secrets of Viscosity Measurement during Thermal Cycling Why Businesses Cant Afford to Miss This Crucial Laboratory Service

In todays fast-paced and competitive business landscape, companies are constantly seeking ways to improve their products, reduce costs, and enhance their market share. One critical aspect that often gets overlooked is the importance of viscosity measurement during thermal cycling. As a leading laboratory service provider, Eurolab offers this cutting-edge technology to help businesses like yours stay ahead of the curve.

Viscosity measurement during thermal cycling is a sophisticated analytical technique used to evaluate the viscosity of materials under various temperature conditions. Its an essential tool for industries such as lubricants, fuels, chemicals, and pharmaceuticals, where changes in viscosity can have significant consequences on product performance, shelf life, and even safety.

In this article, well delve into the world of viscosity measurement during thermal cycling, exploring its significance, benefits, and key applications. By the end of it, youll understand why Eurolabs laboratory service is a must-have for businesses seeking to optimize their products and stay competitive in the market.

What is Viscosity Measurement during Thermal Cycling?

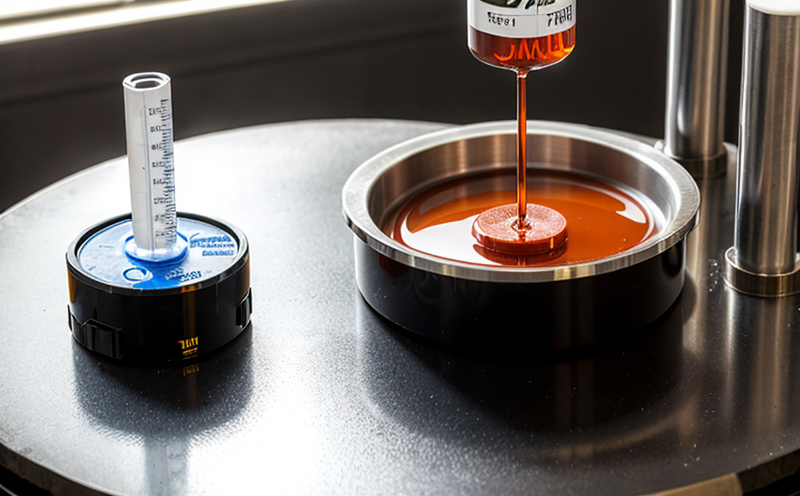

Viscosity measurement during thermal cycling involves subjecting a sample material to a range of temperatures while monitoring its viscosity. This process allows scientists to study how changes in temperature affect the materials flow properties, providing invaluable insights into its behavior under various conditions.

Thermal cycling typically involves heating and cooling cycles, with measurements taken at specific intervals to capture the dynamic changes in viscosity. This approach helps identify key factors that influence viscosity, such as temperature-induced phase transitions, crystallization, or solvent evaporation.

Why is Viscosity Measurement during Thermal Cycling Essential for Businesses?

In todays world of increasingly complex materials and manufacturing processes, understanding how your products behave under various conditions is crucial. Eurolabs viscosity measurement during thermal cycling service provides unparalleled benefits to businesses across industries

Improved Product Performance By analyzing the effect of temperature on viscosity, you can optimize your products performance in real-world applications, reducing wear and tear on machinery, and ensuring smoother operation.

Enhanced Shelf Life Understanding how temperature affects your products viscosity enables you to store it under optimal conditions, reducing degradation and spoilage risks.

Increased Safety Knowing the thermal properties of your materials helps prevent accidents caused by unexpected changes in viscosity during handling or storage.

The Key Benefits of Viscosity Measurement during Thermal Cycling

Here are some key advantages of using Eurolabs laboratory service

Accurate Predictions Our expert analysis provides reliable predictions about how temperature will affect your products viscosity, enabling informed decision-making.

Improved Formulation Control By understanding the thermal behavior of your materials, you can adjust formulations to achieve optimal performance.

Reduced Testing Time and Costs Eurolabs advanced equipment and expertise accelerate testing cycles, saving time and resources.

Comprehensive QA Section

Still unsure about viscosity measurement during thermal cycling? Here are some frequently asked questions that address common concerns

Q What is the benefit of measuring viscosity during thermal cycling?

A This technique allows you to understand how temperature affects your products flow properties, enabling informed decisions on formulation and storage.

Q How does Eurolabs service compare to other laboratory services?

A Our state-of-the-art equipment, combined with expert analysis, ensures accurate and reliable results that meet or exceed industry standards.

Q Can I use this technique for a wide range of materials?

A Yes! Viscosity measurement during thermal cycling is applicable to various materials, including lubricants, fuels, chemicals, and pharmaceuticals.

Q What kind of equipment does Eurolab use for viscosity measurements?

A We utilize cutting-edge rheometers and thermal cyclers that are specifically designed for this application, ensuring precise temperature control and accurate measurements.

Why Choose Eurolabs Viscosity Measurement during Thermal Cycling Service?

With Eurolabs expertise and advanced technology, you can

Stay ahead of the competition By optimizing your products performance and shelf life, youll maintain a market edge.

Reduce costs Our efficient testing process saves time and resources.

Enhance product safety Accurate predictions help prevent accidents caused by temperature-induced viscosity changes.

Dont miss this opportunity to revolutionize your business with Eurolabs viscosity measurement during thermal cycling service. Contact us today to discover how our laboratory expertise can propel your products to new heights of performance, shelf life, and safety.