Viscosity testing for high-viscosity adhesives

The Importance of Viscosity Testing for High-Viscosity Adhesives A Critical Service for Businesses

In the world of manufacturing and quality control, ensuring that adhesives meet specific viscosity standards is crucial for various industries such as aerospace, automotive, construction, and more. High-viscosity adhesives are used in a wide range of applications where strength, durability, and reliability are paramount. However, these complex materials can be notoriously difficult to work with, often presenting challenges during production and application.

This is where viscosity testing for high-viscosity adhesives comes into play an essential laboratory service that helps businesses guarantee the performance and consistency of their adhesive products. In this article, we will delve into the significance of viscosity testing for high-viscosity adhesives and explore the benefits it provides to manufacturers.

What is Viscosity Testing for High-Viscosity Adhesives?

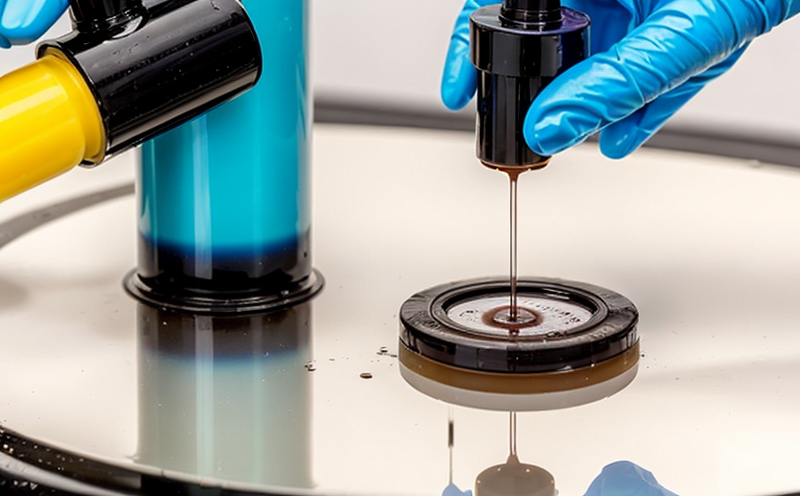

Viscosity testing measures the flow behavior of liquids or semi-solids, providing a crucial indicator of an adhesives properties. It assesses how easily the material flows under stress, which is critical in determining its suitability for various applications. For high-viscosity adhesives, viscosity testing involves subjecting the material to specific conditions to evaluate its fluidity and resistance to flow.

The Advantages of Viscosity Testing for High-Viscosity Adhesives

At Eurolab, our laboratory service provides comprehensive viscosity testing for high-viscosity adhesives. Here are some key benefits of utilizing this critical service

Ensures Compliance with Industry Standards Our expertise and state-of-the-art equipment enable us to test your high-viscosity adhesives according to the latest industry standards. This ensures that your products meet regulatory requirements, preventing costly rejections and recalls.

Optimizes Production Processes By identifying any issues related to viscosity, our laboratory testing helps you refine your production procedures, ensuring efficient manufacturing processes and minimizing downtime.

Enhances Adhesive Performance Viscosity testing enables us to evaluate the flow behavior of your adhesives under various conditions. This knowledge allows for adjustments to be made, resulting in improved product performance and longevity.

Reduces Material Waste Our detailed analysis helps you understand the viscoelastic properties of your high-viscosity adhesives, enabling targeted material optimization and minimizing waste generation.

Supports Quality Control and Assurance By having a thorough understanding of your adhesives viscosity characteristics, you can develop effective quality control measures, ensuring consistent product performance and meeting customer expectations.

Fosters Innovation and RD Our expertise in viscosity testing for high-viscosity adhesives enables us to collaborate with manufacturers to push the boundaries of adhesive technology. This results in new applications, improved formulations, and enhanced material properties.

Benefits for Specific Industries

Viscosity testing for high-viscosity adhesives has far-reaching implications across various sectors

Aerospace High-strength, temperature-resistant adhesives are crucial in aerospace manufacturing. Our viscosity testing ensures these materials meet the exacting standards required for this demanding industry.

Automotive In the automotive sector, adhesives play a critical role in bonding components and ensuring structural integrity. Eurolabs expertise in viscosity testing helps manufacturers optimize adhesive performance and durability.

Construction High-viscosity adhesives are commonly used in construction to bond building materials. Our laboratory service ensures these products meet rigorous standards for durability, strength, and workability.

QA Viscosity Testing for High-Viscosity Adhesives

We understand that questions may arise regarding viscosity testing for high-viscosity adhesives. Here are some frequently asked questions and their answers

Q What equipment is used for viscosity testing?

A Eurolab employs state-of-the-art instruments, including viscometers and rheometers, to accurately measure the flow behavior of your high-viscosity adhesives.

Q How do I prepare my adhesive samples for testing?

A Our expert technicians will guide you through the sample preparation process to ensure accurate results.

Q What are the most common types of viscometers used in viscosity testing?

A We utilize various types of viscometers, including capillary viscometers and rotating cylinder viscometers, depending on the specific requirements of your high-viscosity adhesives.

Q Can I send my adhesive samples to Eurolab for testing?

A Yes! We accept shipments of your adhesive samples from anywhere in the world, ensuring seamless laboratory testing services.

Q What kind of information can I expect after viscosity testing?

A Our comprehensive report provides detailed analysis and recommendations, enabling you to refine your production processes and material formulations for improved performance and efficiency.

Conclusion

In conclusion, viscosity testing for high-viscosity adhesives is a critical laboratory service that supports the development and manufacturing of high-performance materials. At Eurolab, our team of experts is dedicated to providing precise analysis and insightful recommendations, empowering businesses to optimize their adhesive products and processes. Dont compromise on quality trust us to ensure your high-viscosity adhesives meet the highest standards for performance, reliability, and durability.