Assessing how different materials used in products perform under mechanical loading

Assessing How Different Materials Used in Products Perform Under Mechanical Loading A Crucial Laboratory Service for Businesses

In todays fast-paced and highly competitive market, businesses are constantly seeking ways to improve their products performance, reliability, and overall value proposition. One crucial aspect of product development is assessing how different materials used in products perform under mechanical loading. This laboratory service, provided by Eurolab, is an essential tool for companies looking to ensure the longevity, durability, and safety of their products.

What is Mechanical Loading?

Mechanical loading refers to the physical forces that a material or component must withstand during its intended use. These forces can include compressive loads, tensile loads, shear loads, and torsional loads, among others. The performance of materials under mechanical loading is critical in determining the overall success of a product.

Why is Assessing Materials Under Mechanical Loading Essential for Businesses?

Companies that fail to assess their products material properties under mechanical loading risk facing severe consequences, including

Product failure and recall

Damage to reputation and brand value

Financial losses due to reduced sales and increased warranty claims

On the other hand, businesses that prioritize material testing and evaluation can reap numerous benefits, including

Advantages of Using Eurolabs Mechanical Loading Assessment Service

Improved Product Reliability

Reduced risk of product failure and recall

Increased confidence in product performance and longevity

Enhanced reputation and brand value through demonstration of commitment to quality

Enhanced Material Selection

Accurate selection of materials that meet specific mechanical loading requirements

Reduced material costs through optimized material usage

Improved product weight reduction through strategic material selection

Increased Efficiency and Cost Savings

Streamlined product development process through early identification of material weaknesses

Reduced testing time and cost through targeted testing strategies

Improved product design for manufacturability, reducing production costs and lead times

Compliance with Industry Regulations

Ensured compliance with industry standards and regulations regarding material properties and performance

Avoidance of costly rework or redesign due to non-compliance

Enhanced confidence in meeting customer expectations and requirements

How Does Eurolabs Mechanical Loading Assessment Service Work?

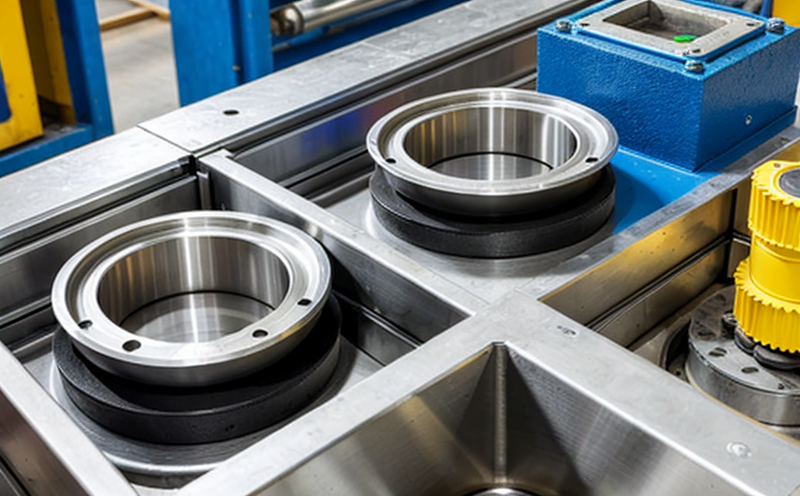

Our team of expert technicians and engineers use state-of-the-art equipment and techniques to assess the mechanical loading behavior of a wide range of materials, including metals, polymers, ceramics, and composites. Our comprehensive testing program includes

Tensile testing

Compressive testing

Shear testing

Torsional testing

Impact testing

Frequently Asked Questions

Q What types of products can benefit from mechanical loading assessment?

A Any product that is subject to mechanical stress, including but not limited to, aerospace components, automotive parts, medical devices, and consumer goods.

Q How do I prepare my materials for testing?

A Materials should be properly cleaned, prepared, and packaged according to our guidelines to ensure accurate and reliable results.

Q Can Eurolab provide testing services for custom or proprietary materials?

A Yes, we have expertise in testing a wide range of materials and can accommodate unique material requirements.

Q What kind of report will I receive after testing is completed?

A Our comprehensive report includes detailed test data, analysis, and recommendations for material selection and product design optimization.

Why Choose Eurolabs Mechanical Loading Assessment Service?

At Eurolab, we understand the importance of accurate and reliable material testing in ensuring product success. Our state-of-the-art facilities, expert team, and commitment to quality make us the ideal partner for businesses seeking to improve their products performance under mechanical loading.

By partnering with Eurolab, you can

Trust our expertise and reliability

Receive comprehensive test data and analysis

Benefit from optimized material selection and product design

Dont risk your businesss reputation or bottom line. Contact us today to learn more about how Eurolabs mechanical loading assessment service can help take your products to the next level.

-

Testing the mechanical durability of consumer products under stress conditions

-

Simulating pressure, bending, and stretching to evaluate how products perform under mechanical load

-

Assessing the tensile and compression strength of consumer goods to prevent structural failure

-

Testing for cracks, deformations, and material fatigue under prolonged mechanical stress

-

Evaluating how consumer products react to forces like twisting, pulling, and pushing

-

Simulating real-world mechanical stresses to test product reliability in everyday use

-

Testing for failure points or weakness in critical components of consumer goods under stress

-

Evaluating the long-term effects of repeated mechanical stress on product lifespan

-

Testing the ability of consumer products to withstand physical manipulation and heavy use

-

Simulating mechanical stress in environments where products are exposed to varying pressures or forces

-

Testing the mechanical integrity of products designed to withstand extreme use, such as tools or sports equipment

-

Evaluating the failure modes of products when exposed to excessive forces

-

Assessing the performance of locking mechanisms, latches, and other components under mechanical stress

-

Testing for bending or breaking points in products like chairs, tables, and kitchenware

-

Verifying product safety and functionality under mechanical loading conditions

-

Assessing the impact of stress on non-visible components of the product, such as internal wiring

-

Testing for early signs of wear or breakage in products subjected to mechanical forces

-

Simulating common real-life scenarios that involve mechanical stress on consumer goods

-

Ensuring that products meet durability standards when subjected to mechanical challenges