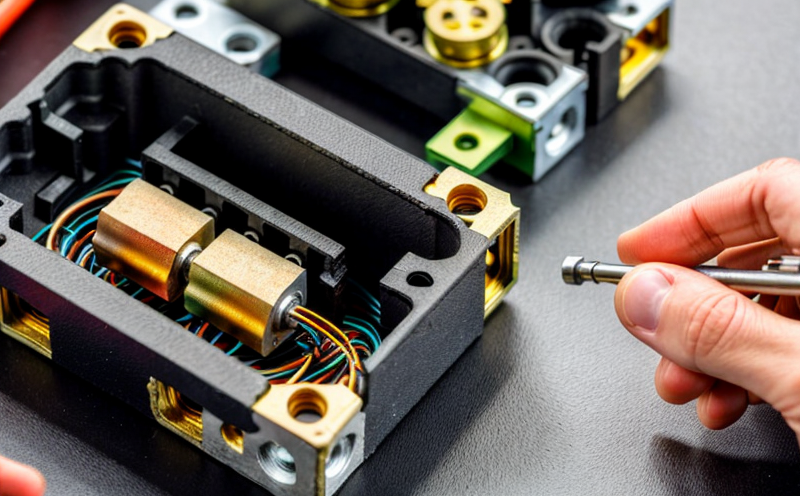

Assessing the impact of stress on non-visible components of the product, such as internal wiring

The Hidden Threats to Your Products Reliability Assessing the Impact of Stress on Non-Visible Components

In todays fast-paced business landscape, product reliability is more crucial than ever. Manufacturers are constantly pushing the boundaries of innovation, but the relentless pursuit of efficiency and cost-effectiveness can sometimes overlook a critical aspect of product development the hidden threats to reliability. For many businesses, this blind spot lies in the non-visible components of their products the internal wiring, for instance.

At Eurolab, we specialize in providing laboratory services that help businesses like yours identify and mitigate these risks before they become major problems. In this article, well delve into the importance of assessing the impact of stress on non-visible components, such as internal wiring, and explore the numerous benefits of doing so.

The Silent Saboteurs What are Non-Visible Components?

Non-visible components refer to the internal parts of a product that are not easily accessible or visible to the naked eye. These include everything from intricate electronic circuits to delicate mechanical assemblies. While they may be out of sight, their impact on your products reliability and performance can be significant.

Internal wiring, in particular, is a prime example of a non-visible component that deserves careful attention. Its the lifeblood of many modern products, responsible for transmitting data, power, and control signals with precision and speed. However, internal wiring is also prone to damage from various sources, including stress, temperature fluctuations, and physical forces.

The Consequences of Neglecting Non-Visible Components

Failing to assess the impact of stress on non-visible components can have far-reaching consequences for your business

Product Failure A malfunctioning internal component can cause a product to fail prematurely, resulting in costly recalls, lost revenue, and damage to your brand reputation.

Increased Maintenance Costs Neglecting non-visible components can lead to more frequent repairs, replacements, and maintenance procedures, straining your resources and budgets.

Reduced Product Lifespan Internal wear and tear can reduce the overall lifespan of a product, forcing customers to replace it sooner rather than later and lose confidence in your brand.

The Benefits of Assessing Stress on Non-Visible Components

So, why should you invest time and resources into assessing the impact of stress on non-visible components? Here are just some of the advantages

Improved Product Reliability By identifying potential weaknesses in internal components, you can design more robust products that better withstand various stresses and loads.

Enhanced Customer Satisfaction Products with reduced failure rates and longer lifespans will naturally lead to increased customer satisfaction, loyalty, and retention.

Cost Savings Identifying and addressing issues early on can save you money by reducing the need for costly repairs, replacements, and maintenance procedures.

Compliance and Certification Assessing stress on non-visible components helps ensure your products meet industry standards and regulations, making it easier to obtain certifications and compliance marks.

The Eurolab Advantage Expert Laboratory Services

At Eurolab, we offer comprehensive laboratory services designed to help businesses like yours assess the impact of stress on non-visible components. Our team of experienced experts utilizes state-of-the-art equipment and techniques to simulate various environmental conditions and test internal components under realistic scenarios.

Some of our specialized services include

Environmental Testing We subject products to extreme temperatures, humidity levels, and vibration to simulate real-world conditions.

Mechanical Testing Our engineers apply precise loads and forces to assess a products mechanical strength and durability.

Electrical Testing We evaluate the electrical performance and integrity of internal wiring and components under various stress conditions.

Frequently Asked Questions

Here are some common questions about assessing the impact of stress on non-visible components

Q What types of products benefit from this assessment?

A Any product with complex internal components, such as electronic devices, mechanical assemblies, or industrial equipment.

Q How do I know if my product requires this assessment?

A If youre experiencing frequent failures, maintenance issues, or concerns about product reliability, its likely that assessing stress on non-visible components is essential for your business.

Q What kind of data and insights can I expect from Eurolabs laboratory services?

A Our comprehensive reports provide detailed information on the performance and reliability of your products under various stress conditions. This allows you to make informed decisions about design improvements, material selection, or maintenance procedures.

Conclusion

Assessing the impact of stress on non-visible components is no longer a nicety its a necessity in todays competitive business landscape. By identifying potential weaknesses and vulnerabilities in internal components, businesses can improve product reliability, enhance customer satisfaction, and reduce costs. At Eurolab, were committed to providing expert laboratory services that help you make data-driven decisions about your products performance under various stress conditions.

Dont let the silent saboteurs of non-visible components jeopardize your businesss success. Contact us today to learn more about our comprehensive laboratory services and start building a more reliable, efficient, and competitive product line.

-

Testing the mechanical durability of consumer products under stress conditions

-

Simulating pressure, bending, and stretching to evaluate how products perform under mechanical load

-

Assessing the tensile and compression strength of consumer goods to prevent structural failure

-

Testing for cracks, deformations, and material fatigue under prolonged mechanical stress

-

Evaluating how consumer products react to forces like twisting, pulling, and pushing

-

Simulating real-world mechanical stresses to test product reliability in everyday use

-

Testing for failure points or weakness in critical components of consumer goods under stress

-

Assessing how different materials used in products perform under mechanical loading

-

Evaluating the long-term effects of repeated mechanical stress on product lifespan

-

Testing the ability of consumer products to withstand physical manipulation and heavy use

-

Simulating mechanical stress in environments where products are exposed to varying pressures or forces

-

Testing the mechanical integrity of products designed to withstand extreme use, such as tools or sports equipment

-

Evaluating the failure modes of products when exposed to excessive forces

-

Assessing the performance of locking mechanisms, latches, and other components under mechanical stress

-

Testing for bending or breaking points in products like chairs, tables, and kitchenware

-

Verifying product safety and functionality under mechanical loading conditions

-

Testing for early signs of wear or breakage in products subjected to mechanical forces

-

Simulating common real-life scenarios that involve mechanical stress on consumer goods

-

Ensuring that products meet durability standards when subjected to mechanical challenges