Testing for cracks, deformations, and material fatigue under prolonged mechanical stress

Uncover Hidden Risks Why Testing for Cracks, Deformations, and Material Fatigue is a Game-Changer for Your Business

As a business owner, you understand the importance of ensuring the safety and reliability of your products and equipment. However, even with rigorous testing and quality control measures in place, defects can still occur, putting people and assets at risk. Thats where Eurolab comes in a trusted laboratory service provider that offers comprehensive testing for cracks, deformations, and material fatigue under prolonged mechanical stress.

In this article, well delve into the world of material testing and explore why its essential to identify potential weaknesses before they become catastrophic failures. Well discuss the benefits of using Eurolabs services and highlight key advantages that can help you make informed decisions about your businesss quality control procedures.

What is Testing for Cracks, Deformations, and Material Fatigue?

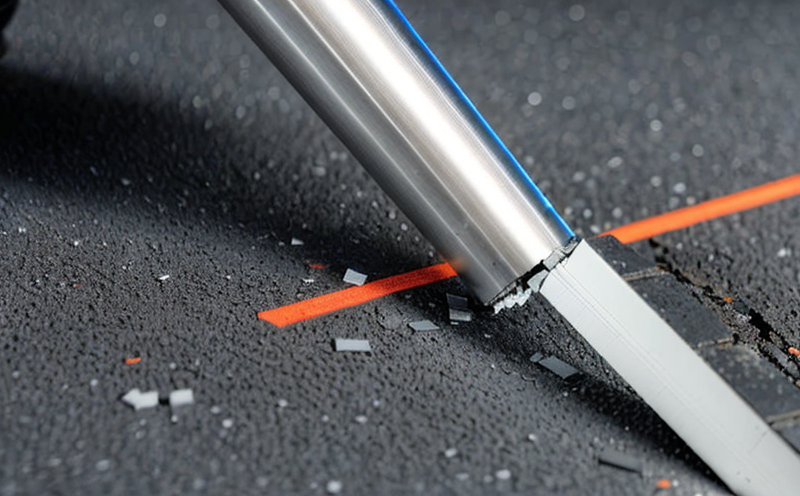

Testing for cracks, deformations, and material fatigue under prolonged mechanical stress involves a range of laboratory techniques designed to simulate real-world conditions. Our expert technicians use sophisticated equipment and protocols to evaluate the integrity of materials, identifying potential vulnerabilities that could lead to premature failure.

This type of testing is critical in various industries, including

Aerospace Ensuring the safety and durability of aircraft components and engines

Automotive Verifying the reliability of vehicle parts and systems

Energy Evaluating the performance and lifespan of machinery used in power generation

Industrial Assessing the quality of equipment and materials used in manufacturing

The Advantages of Using Eurolabs Services

By choosing Eurolab for your material testing needs, youll benefit from

Improved Safety Identify potential risks before they cause harm to people or assets, ensuring a safer working environment

Reduced Costs Prevent costly repairs and replacements by detecting weaknesses early on

Enhanced Product Reliability Gain confidence in the quality of your products with accurate assessments of material performance

Compliance with Regulations Meet industry standards and regulatory requirements with our expert testing services

Informed Decision-Making Receive unbiased, data-driven results to inform your product development and maintenance strategies

Why is Material Fatigue Testing Essential?

Material fatigue occurs when a material is subjected to repeated stress or strain, leading to microscopic cracks that can eventually cause catastrophic failure. Identifying potential weaknesses in this area can help you

Avoid Catastrophic Failures Prevent equipment breakdowns and accidents by detecting material fatigue early

Extend Equipment Lifespan Optimize maintenance schedules and extend the useful life of your assets

Reduce Maintenance Costs Minimize downtime and repair expenses by addressing issues proactively

Benefits of Cracks and Deformations Testing

Crack detection and deformation assessment are critical components of our material testing services. By identifying cracks and deformities, you can

Detect Hidden Defects Identify internal flaws that may not be visible to the naked eye

Prevent Equipment Malfunction Avoid costly repairs by detecting potential issues before they cause problems

Ensure Component Reliability Verify the integrity of critical components to ensure smooth operation

Benefits of Prolonged Mechanical Stress Testing

Our laboratory simulates real-world conditions to assess material performance under prolonged mechanical stress. This includes

Evaluation of Material Strength Determine a materials resistance to fatigue, creep, and other forms of degradation

Assessment of Component Lifespan Estimate the useful life of equipment and components based on our test results

Optimization of Maintenance Schedules Use data-driven insights to schedule maintenance and repairs more effectively

Frequently Asked Questions

Q What types of materials can be tested?

A Eurolab offers testing services for a wide range of materials, including metals, alloys, polymers, ceramics, and composites.

Q How do I prepare my samples for testing?

A Our experienced technicians will guide you through the preparation process to ensure your samples are properly conditioned for testing.

Q What types of equipment can be tested?

A We test various equipment components, including gears, bearings, shafts, fasteners, and more.

Q Can I request custom testing protocols?

A Yes! Our expert technicians will work with you to develop a customized testing plan tailored to your specific needs.

Conclusion

Dont let hidden risks compromise the safety and reliability of your business. Eurolabs comprehensive testing services for cracks, deformations, and material fatigue under prolonged mechanical stress provide unparalleled insights into material performance. By partnering with us, youll gain confidence in the quality of your products, reduce costs associated with repairs and replacements, and ensure compliance with industry regulations.

Dont wait until its too late uncover hidden risks and optimize your business operations with Eurolabs expert laboratory services. Contact us today to learn more about our testing capabilities and how we can help you achieve success in a competitive marketplace!

-

Testing the mechanical durability of consumer products under stress conditions

-

Simulating pressure, bending, and stretching to evaluate how products perform under mechanical load

-

Assessing the tensile and compression strength of consumer goods to prevent structural failure

-

Evaluating how consumer products react to forces like twisting, pulling, and pushing

-

Simulating real-world mechanical stresses to test product reliability in everyday use

-

Testing for failure points or weakness in critical components of consumer goods under stress

-

Assessing how different materials used in products perform under mechanical loading

-

Evaluating the long-term effects of repeated mechanical stress on product lifespan

-

Testing the ability of consumer products to withstand physical manipulation and heavy use

-

Simulating mechanical stress in environments where products are exposed to varying pressures or forces

-

Testing the mechanical integrity of products designed to withstand extreme use, such as tools or sports equipment

-

Evaluating the failure modes of products when exposed to excessive forces

-

Assessing the performance of locking mechanisms, latches, and other components under mechanical stress

-

Testing for bending or breaking points in products like chairs, tables, and kitchenware

-

Verifying product safety and functionality under mechanical loading conditions

-

Assessing the impact of stress on non-visible components of the product, such as internal wiring

-

Testing for early signs of wear or breakage in products subjected to mechanical forces

-

Simulating common real-life scenarios that involve mechanical stress on consumer goods

-

Ensuring that products meet durability standards when subjected to mechanical challenges