Testing for early signs of wear or breakage in products subjected to mechanical forces

Testing for Early Signs of Wear or Breakage Protecting Your Business with Eurolabs Expertise

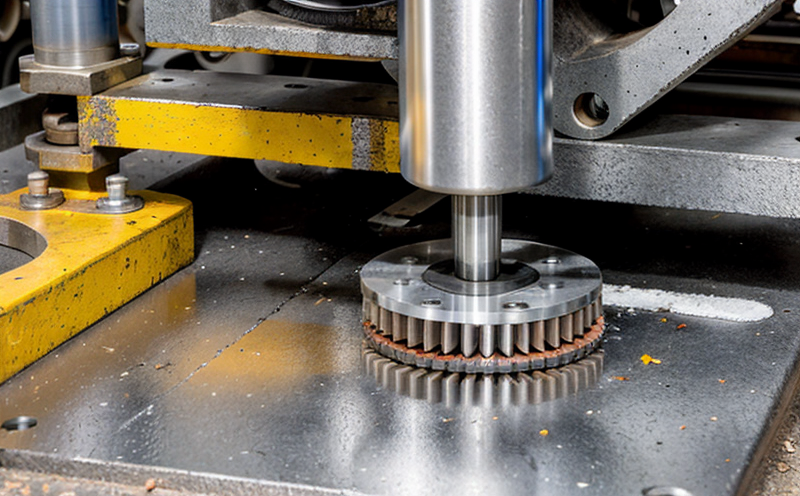

In todays competitive market, product reliability and longevity are crucial factors that can make or break a business. Products subjected to mechanical forces, such as machinery parts, automotive components, and industrial equipment, are particularly susceptible to wear and tear over time. This can lead to costly downtime, reduced productivity, and even catastrophic failures that can have severe consequences for businesses.

At Eurolab, we understand the importance of detecting early signs of wear or breakage in products subjected to mechanical forces. Our laboratory service is designed to help businesses like yours identify potential issues before they become major problems, ensuring your products are safe, reliable, and compliant with industry standards.

The Importance of Testing for Early Signs of Wear or Breakage

Testing for early signs of wear or breakage is not just a precautionary measure; its an essential step in maintaining product integrity and preventing costly failures. Here are some compelling reasons why

Reduced Downtime Regular testing helps identify potential issues before they cause equipment failure, minimizing downtime and ensuring smooth production processes.

Increased Productivity By detecting early signs of wear or breakage, businesses can replace faulty components promptly, reducing the risk of production delays and maintaining productivity levels.

Cost Savings Identifying and addressing problems early on saves companies from incurring costly repairs, replacement costs, and potential liabilities.

Improved Safety Regular testing helps prevent accidents and injuries caused by faulty equipment or products, ensuring a safer working environment for employees.

Benefits of Eurolabs Testing Services

Our laboratory service offers numerous benefits to businesses, including

Expert Analysis Our team of experienced engineers and technicians uses state-of-the-art equipment to conduct thorough analyses and provide accurate results.

Customized Solutions We tailor our testing services to meet the specific needs of your business, ensuring that our solutions are effective and efficient.

Compliance with Industry Standards Our tests are designed to meet or exceed industry standards, giving you peace of mind knowing that your products comply with regulatory requirements.

Timely Results We prioritize fast turnaround times without compromising on accuracy, allowing you to make informed decisions quickly.

Key Benefits of Eurolabs Testing Services

Here are some key benefits of our testing services

Early Detection of Wear or Breakage Our tests help identify potential issues before they become major problems.

Improved Product Reliability Regular testing ensures that your products meet industry standards and are reliable in operation.

Reduced Maintenance Costs By detecting early signs of wear or breakage, businesses can reduce maintenance costs and extend the lifespan of their equipment.

Enhanced Customer Satisfaction Our services help ensure that your products perform as expected, leading to increased customer satisfaction and loyalty.

QA Frequently Asked Questions

At Eurolab, we understand that our clients may have questions about our testing services. Here are some frequently asked questions

Q What types of products can be tested?

A Our laboratory service is designed for a wide range of products subjected to mechanical forces, including machinery parts, automotive components, and industrial equipment.

Q How do I prepare my product for testing?

A Please follow our guidelines for preparing your product for testing, which can be found on our website or by contacting our team.

Q What kind of results can I expect from the test?

A Our tests provide detailed reports and recommendations for improving product reliability and reducing maintenance costs.

Q How long does it take to receive results?

A We prioritize fast turnaround times without compromising on accuracy, ensuring that you receive timely results.

Conclusion

In conclusion, testing for early signs of wear or breakage is a critical aspect of maintaining product integrity and preventing costly failures. At Eurolab, we offer expert laboratory services designed to help businesses like yours identify potential issues before they become major problems.

By partnering with us, you can enjoy numerous benefits, including reduced downtime, increased productivity, cost savings, and improved safety. Our team of experienced engineers and technicians uses state-of-the-art equipment to provide accurate results, ensuring that your products meet or exceed industry standards.

Dont let wear or breakage compromise your businesss success. Choose Eurolab for expert testing services that deliver peace of mind and protect your bottom line. Contact us today to learn more about our laboratory service and how we can help you achieve product reliability and longevity.

-

Testing the mechanical durability of consumer products under stress conditions

-

Simulating pressure, bending, and stretching to evaluate how products perform under mechanical load

-

Assessing the tensile and compression strength of consumer goods to prevent structural failure

-

Testing for cracks, deformations, and material fatigue under prolonged mechanical stress

-

Evaluating how consumer products react to forces like twisting, pulling, and pushing

-

Simulating real-world mechanical stresses to test product reliability in everyday use

-

Testing for failure points or weakness in critical components of consumer goods under stress

-

Assessing how different materials used in products perform under mechanical loading

-

Evaluating the long-term effects of repeated mechanical stress on product lifespan

-

Testing the ability of consumer products to withstand physical manipulation and heavy use

-

Simulating mechanical stress in environments where products are exposed to varying pressures or forces

-

Testing the mechanical integrity of products designed to withstand extreme use, such as tools or sports equipment

-

Evaluating the failure modes of products when exposed to excessive forces

-

Assessing the performance of locking mechanisms, latches, and other components under mechanical stress

-

Testing for bending or breaking points in products like chairs, tables, and kitchenware

-

Verifying product safety and functionality under mechanical loading conditions

-

Assessing the impact of stress on non-visible components of the product, such as internal wiring

-

Simulating common real-life scenarios that involve mechanical stress on consumer goods

-

Ensuring that products meet durability standards when subjected to mechanical challenges