Ensuring that products meet durability standards when subjected to mechanical challenges

Ensuring Products Meet Durability Standards Why Eurolabs Laboratory Services are a Game-Changer

In todays fast-paced and highly competitive business landscape, product durability is more crucial than ever. With an increasing number of consumers demanding high-quality products that can withstand the rigors of daily use, manufacturers must ensure their goods meet stringent durability standards. This is where Eurolabs laboratory services come in our team of experts helps businesses like yours validate the mechanical performance of your products, ensuring they meet or exceed industry expectations.

What is Ensuring Products Meet Durability Standards when Subjected to Mechanical Challenges?

Ensuring products meet durability standards when subjected to mechanical challenges involves a series of rigorous tests and evaluations designed to simulate real-world use conditions. These assessments help identify potential weaknesses in product design or material selection, allowing manufacturers to make informed decisions about improvements before they hit the market.

At Eurolab, we understand that product reliability is critical to building trust with customers and maintaining a strong reputation in the industry. Our comprehensive laboratory services are designed to support businesses like yours by providing objective, unbiased assessments of your products mechanical performance.

The Advantages of Using Ensuring Products Meet Durability Standards when Subjected to Mechanical Challenges

Partnering with Eurolab for durability testing offers numerous benefits for manufacturers

Reduced Warranty and Liability Costs By identifying potential weaknesses before launch, you can minimize warranty claims and liability costs associated with product failures.

Increased Customer Satisfaction When products meet or exceed durability standards, customers are more likely to be satisfied with their purchases, leading to repeat business and positive word-of-mouth marketing.

Improved Brand Reputation Demonstrating a commitment to quality through rigorous testing helps establish your brand as reliable and trustworthy in the eyes of consumers and industry peers alike.

Compliance with Industry Regulations Our laboratory services ensure that your products meet or exceed regulatory requirements, reducing the risk of costly recalls or fines associated with non-compliance.

Cost Savings Early identification of design flaws or material weaknesses enables you to make targeted improvements before production begins, saving time and resources in the long run.

Benefits for Different Industries

While our laboratory services are versatile and adaptable to various industries, we have a particular expertise in serving

Aerospace and Defense We provide critical testing and evaluation of components for safety-critical applications.

Automotive Our experts assess the mechanical performance of vehicles, ensuring compliance with regulatory standards and industry best practices.

Consumer Goods From appliances to electronics, our services help manufacturers validate product durability in real-world use conditions.

How Does Eurolabs Laboratory Services Work?

Our comprehensive testing protocol involves a series of evaluations tailored to your specific product or application. We employ cutting-edge equipment and expert analysis to simulate the mechanical challenges your products will face in the field.

Product Evaluation Our team assesses your products design, materials, and manufacturing processes to identify potential vulnerabilities.

Mechanical Testing We conduct rigorous testing using a range of methods, including

Impact testing (e.g., drop tests)

Vibration testing

Fatigue testing

Wear and tear testing

Data Analysis Our experts analyze the results of each test, providing detailed reports on product performance.

Recommendations for Improvement Based on our findings, we offer actionable recommendations for design improvements or material upgrades.

Frequently Asked Questions (FAQs)

Q What types of products can you test?

A Eurolabs laboratory services are versatile and adaptable to various industries and product types, including aerospace, automotive, consumer goods, and more.

Q How long does the testing process take?

A The duration of our testing protocol varies depending on the complexity of your project. We work closely with each client to ensure timely completion of assessments.

Q Do I need to provide any specific documentation or information prior to testing?

A Yes, please provide detailed product specifications and usage scenarios to help us tailor our assessment to your needs.

Q What are the benefits of working with Eurolab versus conducting in-house testing?

A Our team of experts brings extensive knowledge and experience in testing and analysis. We use cutting-edge equipment and provide unbiased assessments, allowing you to focus on core business activities while ensuring product reliability.

Why Choose Eurolab for Your Durability Testing Needs?

At Eurolab, we understand the importance of rigorous durability testing for manufacturers seeking to build trust with customers and maintain a strong reputation in the industry. Our comprehensive laboratory services offer

Expertise Our team consists of experienced professionals with specialized knowledge in mechanical testing and analysis.

Cutting-Edge Equipment We employ state-of-the-art equipment to simulate real-world use conditions, ensuring accurate assessments.

Objectivity As an independent third-party provider, we offer unbiased evaluations, enabling you to make informed decisions about product improvements.

In conclusion, partnering with Eurolab for durability testing is a strategic decision that can significantly impact your businesss bottom line. By ensuring products meet or exceed industry durability standards when subjected to mechanical challenges, manufacturers can reduce warranty and liability costs, increase customer satisfaction, and maintain a strong brand reputation. Contact us today to learn more about our comprehensive laboratory services and how we can support your product development initiatives.

-

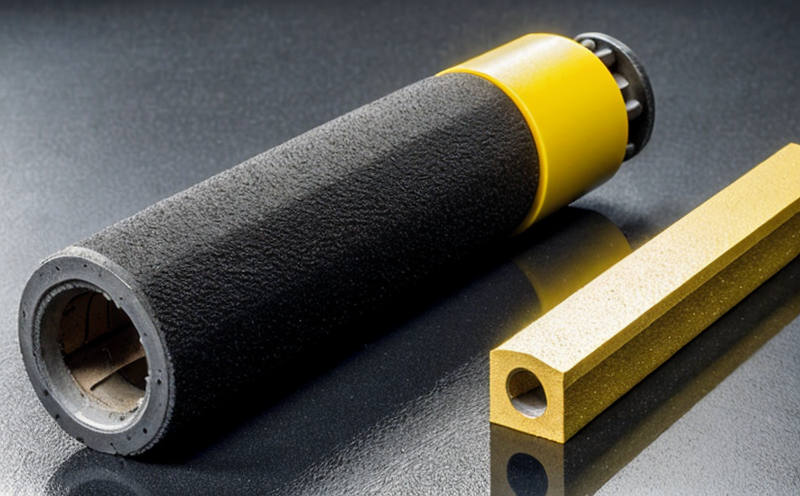

Testing the mechanical durability of consumer products under stress conditions

-

Simulating pressure, bending, and stretching to evaluate how products perform under mechanical load

-

Assessing the tensile and compression strength of consumer goods to prevent structural failure

-

Testing for cracks, deformations, and material fatigue under prolonged mechanical stress

-

Evaluating how consumer products react to forces like twisting, pulling, and pushing

-

Simulating real-world mechanical stresses to test product reliability in everyday use

-

Testing for failure points or weakness in critical components of consumer goods under stress

-

Assessing how different materials used in products perform under mechanical loading

-

Evaluating the long-term effects of repeated mechanical stress on product lifespan

-

Testing the ability of consumer products to withstand physical manipulation and heavy use

-

Simulating mechanical stress in environments where products are exposed to varying pressures or forces

-

Testing the mechanical integrity of products designed to withstand extreme use, such as tools or sports equipment

-

Evaluating the failure modes of products when exposed to excessive forces

-

Assessing the performance of locking mechanisms, latches, and other components under mechanical stress

-

Testing for bending or breaking points in products like chairs, tables, and kitchenware

-

Verifying product safety and functionality under mechanical loading conditions

-

Assessing the impact of stress on non-visible components of the product, such as internal wiring

-

Testing for early signs of wear or breakage in products subjected to mechanical forces

-

Simulating common real-life scenarios that involve mechanical stress on consumer goods