Assessing the strength of critical components like handles, hinges, or levers under torque and tension loads

Assessing the Strength of Critical Components Why It Matters for Your Business

In todays competitive market, ensuring the safety and reliability of your products is crucial to maintaining customer trust and satisfaction. One critical aspect that often goes unnoticed is the assessment of key components like handles, hinges, or levers under torque and tension loads. These seemingly minor elements can have a significant impact on the overall performance and lifespan of your product. At Eurolab, we understand the importance of this laboratory service and are here to guide you through its significance.

What Is Assessing the Strength of Critical Components?

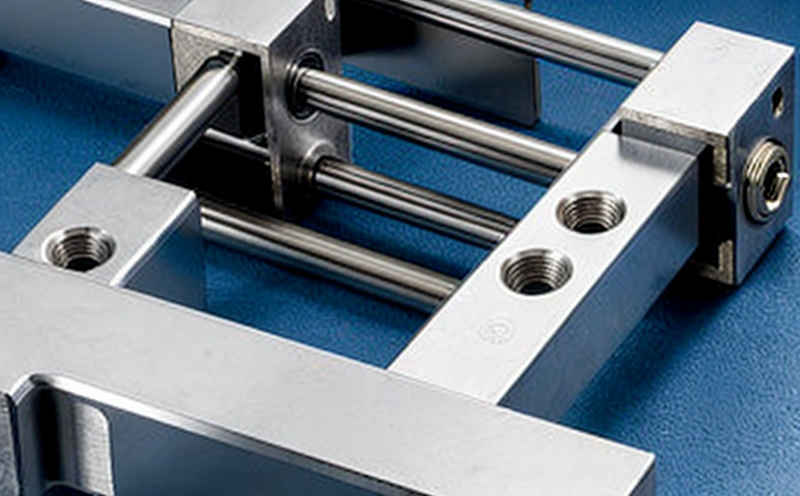

Assessing the strength of critical components involves testing their ability to withstand various loads, including torque and tension. This process evaluates the components material properties, design, and manufacturing quality to ensure it can handle the stresses imposed during normal use or extreme conditions. Torque and tension loads are particularly relevant in industries where heavy-duty applications are common, such as construction, automotive, aerospace, and industrial equipment.

Why Is Assessing the Strength of Critical Components Essential for Businesses?

There are several reasons why businesses should prioritize assessing the strength of critical components

Product Reliability By evaluating the robustness of key components, manufacturers can ensure their products meet or exceed customer expectations. This leads to increased customer satisfaction and loyalty.

Reduced Liability Assessing component strength helps minimize the risk of product failure, which can result in costly lawsuits, damaged reputation, and lost revenue.

Compliance with Regulations Many industries are subject to strict regulations regarding product safety and performance. Conducting thorough assessments ensures compliance with these standards, reducing the likelihood of fines or penalties.

Improved Design and Development The data collected from these tests can inform design improvements, leading to more efficient and effective products that better meet customer needs.

Advantages of Using Assessing the Strength of Critical Components

Eurolabs laboratory service offers several benefits to businesses

Customized Testing Our team works closely with clients to develop tailored test protocols that simulate real-world conditions and address specific product concerns.

Highly Accurate Results Utilizing state-of-the-art equipment and expert technicians, we provide precise measurements of component strength and performance.

Rapid Turnaround Times We understand the importance of timely results and strive to deliver comprehensive reports within a few days, enabling businesses to make informed decisions quickly.

Expert Consultation Our experienced team provides valuable insights and recommendations for improving product design, reducing costs, or enhancing safety features.

Comprehensive QA Section

Q What types of components can be assessed under torque and tension loads?

A Handles, hinges, levers, screws, bolts, and other critical components that are subject to twisting, bending, or stretching forces.

Q Why is it essential to assess component strength in specific industries?

A Industries with high-stress applications, such as construction, automotive, aerospace, and industrial equipment manufacturing, require robust components to ensure product reliability and safety.

Q What kind of data can I expect from the assessment results?

A Our reports include detailed measurements of component strength, stress analysis, failure modes, and recommendations for design improvements or material upgrades.

Q Can you provide customization options for testing protocols?

A Yes, we work closely with clients to develop tailored test protocols that simulate real-world conditions and address specific product concerns.

Conclusion

Assessing the strength of critical components like handles, hinges, or levers under torque and tension loads is a crucial laboratory service that can make a significant impact on your business. By prioritizing this assessment, you can ensure product reliability, reduce liability, comply with regulations, and improve design and development. At Eurolab, we are committed to providing high-quality testing services that meet the unique needs of each client. Contact us today to learn more about how our laboratory service can benefit your business.

About Eurolab

Eurolab is a leading provider of laboratory services, specializing in the assessment of critical components under torque and tension loads. With a team of experienced experts and state-of-the-art equipment, we deliver accurate results and valuable insights that help businesses improve product design, reduce costs, and enhance safety features. Trust Eurolab for comprehensive testing solutions tailored to your specific needs.

-

Testing the ability of consumer products to withstand twisting or rotational forces without failure

-

Assessing the performance of mechanical components like screws, bolts, and fasteners under tension and torque

-

Evaluating the structural integrity of products that undergo rotational or tensile stress during use

-

Simulating real-world conditions where products are subjected to twisting, pulling, or stretching forces

-

Testing materials for their resistance to deformation when torque or tension is applied

-

Verifying the strength of connections and joints in consumer products like furniture or machinery

-

Assessing the durability of products that need to withstand torque or tension over long periods

-

Testing for potential failure points or weak spots in consumer products exposed to torque or tension

-

Simulating the impact of heavy load or excessive twisting forces on products during use or transport

-

Evaluating the effectiveness of design features that distribute tension or torque evenly across products

-

Testing the mechanical limits of consumer products under both static and dynamic tension or torque conditions

-

Verifying the ability of products to maintain their structural integrity under varying force conditions

-

Assessing the long-term performance of products exposed to cyclic or repetitive torque and tension

-

Testing the resistance of fasteners, adhesives, or bonding materials to torque and tension forces

-

Simulating real-life scenarios like tightening, loosening, or pulling motions to evaluate product strength

-

Testing the tension tolerance of fabrics, ropes, and other flexible materials used in consumer products

-

Verifying that products are designed to distribute stresses evenly and avoid concentration of force

-

Testing for the durability of materials like metals, plastics, and composites under torque or tension

-

Evaluating product failure modes caused by excessive torque or tension, such as cracking, bending, or detachment

-

Simulating various stress conditions to ensure the reliability of products under everyday use and extreme conditions