Testing for potential failure points or weak spots in consumer products exposed to torque or tension

Testing for Potential Failure Points or Weak Spots in Consumer Products Exposed to Torque or Tension A Crucial Service Provided by Eurolab

In todays competitive market, product reliability and durability are no longer just desirable features theyre essential components of a successful business strategy. As consumers become increasingly demanding, manufacturers must ensure that their products can withstand the rigors of daily use and maintain their performance over time. This is where testing for potential failure points or weak spots in consumer products exposed to torque or tension comes into play.

At Eurolab, we offer a comprehensive laboratory service designed to identify and address potential weaknesses in your products before they reach the market. By utilizing our state-of-the-art testing facilities and expert technicians, you can ensure that your products meet the highest standards of quality and reliability.

The Importance of Identifying Potential Failure Points

Product failures can have severe consequences for businesses, including costly recalls, damage to brand reputation, and loss of customer trust. In fact, a study by the Consumer Product Safety Commission found that product recalls cost manufacturers an average of 10 million per year. Moreover, a single major recall can lead to long-term financial losses and reduced market share.

By identifying potential failure points or weak spots in your products, you can take proactive steps to mitigate these risks and prevent costly failures. Our testing services allow you to

Prevent product recalls by identifying and addressing weaknesses before they become a problem

Improve product reliability by ensuring that your products meet the highest standards of quality and performance

Enhance brand reputation by demonstrating a commitment to product safety and customer satisfaction

Reduce costs associated with product failures, including repair or replacement, and potential losses due to lost sales

The Benefits of Testing for Potential Failure Points

Our testing services offer numerous benefits that can help you achieve business success

Enhanced Product Reliability Our rigorous testing protocols ensure that your products meet the highest standards of quality and performance.

Increased Customer Satisfaction By identifying and addressing potential weaknesses, you can reduce the likelihood of product failures and enhance customer satisfaction.

Reduced Costs Avoid costly repairs or replacements by detecting potential failure points early on.

Improved Brand Reputation Demonstrate a commitment to product safety and customer satisfaction, enhancing your brand reputation and trust with customers.

Compliance with Industry Standards Our testing services ensure compliance with industry standards and regulations, reducing the risk of non-compliance penalties.

How Eurolabs Testing Services Work

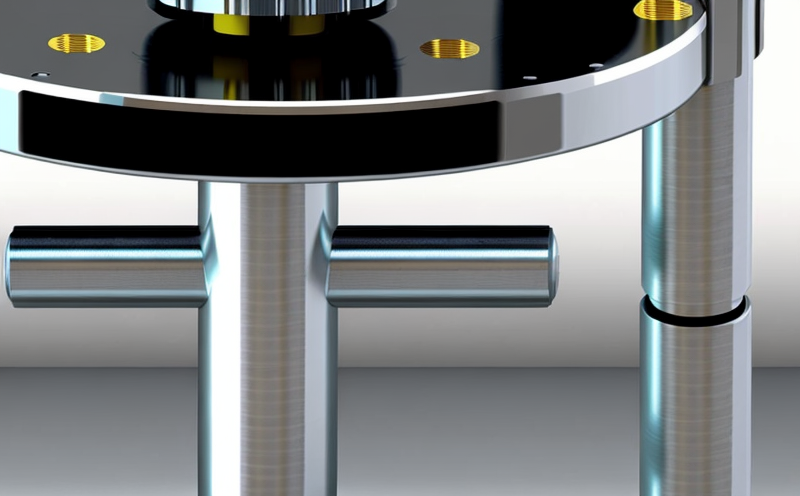

Our team of expert technicians utilizes state-of-the-art equipment to simulate real-world conditions, subjecting your products to a range of tests designed to identify potential failure points or weak spots. Our testing protocols include

Torque and tension testing We apply controlled forces to simulate the stresses that your products may encounter in real-world use.

Cycle testing We subject your products to repeated cycles of stress and relaxation, simulating the effects of daily use over time.

Impact testing We apply controlled impacts to test the resilience of your products.

QA Frequently Asked Questions About Testing for Potential Failure Points

Q What types of products can be tested?

A Our services are suitable for a wide range of consumer products, including electrical appliances, mechanical components, and automotive parts.

Q How do I prepare my product for testing?

A Please ensure that your product is fully assembled and in its final form, as this allows us to simulate real-world conditions accurately.

Q What kind of results can I expect from the testing process?

A Our detailed reports will highlight any potential failure points or weak spots identified during testing, along with recommendations for improvement.

Q Can I request customized testing protocols tailored to my products specific needs?

A Yes. We work closely with our clients to develop customized testing protocols that address their unique requirements and specifications.

Conclusion

In todays competitive market, product reliability and durability are no longer just desirable features theyre essential components of a successful business strategy. By utilizing Eurolabs comprehensive laboratory services for testing potential failure points or weak spots in consumer products exposed to torque or tension, you can

Prevent costly product failures

Enhance brand reputation and customer satisfaction

Reduce costs associated with product repairs or replacements

Dont wait until its too late protect your business by identifying and addressing potential weaknesses today. Contact us at Eurolab to learn more about our laboratory services and schedule a testing program tailored to your specific needs.

-

Testing the ability of consumer products to withstand twisting or rotational forces without failure

-

Assessing the performance of mechanical components like screws, bolts, and fasteners under tension and torque

-

Evaluating the structural integrity of products that undergo rotational or tensile stress during use

-

Simulating real-world conditions where products are subjected to twisting, pulling, or stretching forces

-

Testing materials for their resistance to deformation when torque or tension is applied

-

Verifying the strength of connections and joints in consumer products like furniture or machinery

-

Assessing the durability of products that need to withstand torque or tension over long periods

-

Simulating the impact of heavy load or excessive twisting forces on products during use or transport

-

Evaluating the effectiveness of design features that distribute tension or torque evenly across products

-

Testing the mechanical limits of consumer products under both static and dynamic tension or torque conditions

-

Verifying the ability of products to maintain their structural integrity under varying force conditions

-

Assessing the long-term performance of products exposed to cyclic or repetitive torque and tension

-

Testing the resistance of fasteners, adhesives, or bonding materials to torque and tension forces

-

Simulating real-life scenarios like tightening, loosening, or pulling motions to evaluate product strength

-

Testing the tension tolerance of fabrics, ropes, and other flexible materials used in consumer products

-

Assessing the strength of critical components like handles, hinges, or levers under torque and tension loads

-

Verifying that products are designed to distribute stresses evenly and avoid concentration of force

-

Testing for the durability of materials like metals, plastics, and composites under torque or tension

-

Evaluating product failure modes caused by excessive torque or tension, such as cracking, bending, or detachment

-

Simulating various stress conditions to ensure the reliability of products under everyday use and extreme conditions