Testing materials for their resistance to deformation when torque or tension is applied

Uncover the Secrets of Material Strength Testing for Resistance to Deformation

In todays fast-paced industrial landscape, material selection plays a crucial role in determining the success or failure of various products and applications. From aerospace and automotive to construction and consumer goods, materials are constantly subjected to various types of stress, including torque and tension. However, not all materials can withstand these forces without deforming or failing catastrophically.

This is where testing materials for their resistance to deformation when torque or tension is applied comes in a laboratory service provided by Eurolab that helps businesses ensure the integrity and performance of their products.

In this article, we will delve into the world of material testing, exploring the benefits, advantages, and importance of assessing a materials resilience under stress. Whether youre an engineer, manufacturer, or product designer, understanding the capabilities and limitations of your materials is essential for creating reliable, efficient, and safe products.

What is Material Testing?

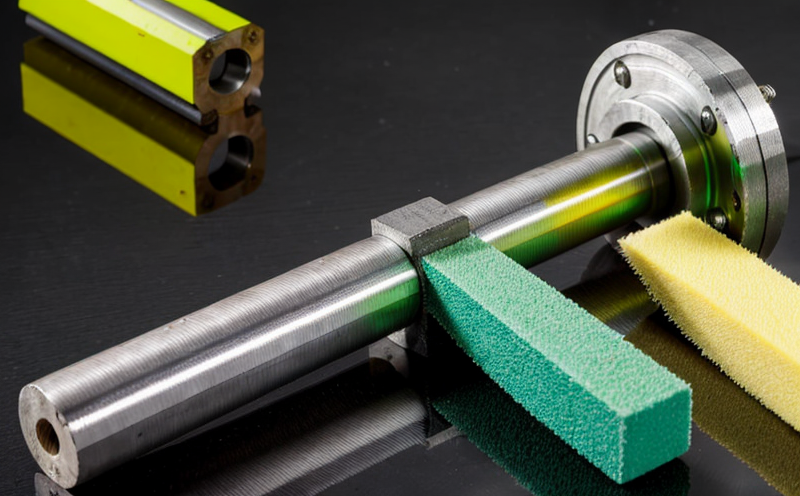

Material testing involves evaluating the physical properties and behavior of a material under various conditions, including torque and tension. By simulating real-world stress scenarios in a controlled laboratory environment, Eurolabs expert technicians can determine how a material will respond to different forces, temperatures, and environmental factors.

This critical process helps manufacturers identify potential weaknesses or vulnerabilities in their products, enabling them to make informed decisions about design modifications, quality control measures, and material substitutions. By investing in material testing, businesses can

Reduce the risk of product failure Identify areas where materials may deform or fail under stress, preventing costly recalls, repairs, or even injuries.

Improve product efficiency Optimize material selection to enhance performance, durability, and energy efficiency.

Enhance safety Ensure that products meet regulatory requirements and industry standards for safety and compliance.

Minimize costs Avoid costly redesigns, rework, or material replacement due to unforeseen weaknesses.

Advantages of Material Testing with Eurolab

By partnering with Eurolab, businesses can benefit from

Expertise and Experience Our team of skilled technicians has extensive knowledge of various testing methods and materials, ensuring accurate and reliable results.

State-of-the-Art Equipment We employ cutting-edge machinery and software to simulate real-world conditions, providing comprehensive data analysis and insights.

Customized Solutions Eurolab offers tailored testing packages to meet specific industry needs, including aerospace, automotive, construction, and more.

Rapid Turnaround Times Our efficient processing ensures timely results, enabling businesses to make informed decisions quickly.

Benefits of Testing Materials for Resistance to Deformation

In addition to the advantages mentioned above, material testing also offers several key benefits

Improved Material Selection By understanding a materials strengths and weaknesses, manufacturers can choose the best-suited materials for their products.

Enhanced Design and Engineering Accurate data from material testing enables designers and engineers to create optimized designs that minimize stress concentrations and maximize performance.

Reduced Material Waste Identifying potential issues early on helps reduce waste by minimizing unnecessary rework or material replacement.

Increased Customer Confidence Demonstrating compliance with industry standards and regulations through material testing can boost customer trust and loyalty.

QA Frequently Asked Questions about Eurolabs Material Testing Services

What types of materials can be tested?

Eurolab offers comprehensive material testing services for a wide range of materials, including metals, polymers, composites, ceramics, and more.

How do I prepare my materials for testing?

Please contact us to discuss specific requirements and guidelines for sample preparation.

What types of testing methods are available?

Our expert technicians utilize various testing techniques, including tensile testing, torque testing, flexural testing, and more.

Can I request customized testing packages or services?

Absolutely! Eurolab offers tailored solutions to meet the unique needs of your business or industry.

How long does material testing typically take?

Turnaround times vary depending on the complexity of the test and the type of analysis required, but we strive to deliver results as quickly as possible.

Conclusion

In an increasingly competitive market where product performance and reliability are paramount, businesses must ensure that their materials can withstand various types of stress. By partnering with Eurolab for material testing services, companies can gain valuable insights into their products strengths and weaknesses, driving innovation, efficiency, and safety.

Dont leave your products integrity to chance choose Eurolab for expert material testing and unlock the full potential of your materials today.

-

Testing the ability of consumer products to withstand twisting or rotational forces without failure

-

Assessing the performance of mechanical components like screws, bolts, and fasteners under tension and torque

-

Evaluating the structural integrity of products that undergo rotational or tensile stress during use

-

Simulating real-world conditions where products are subjected to twisting, pulling, or stretching forces

-

Verifying the strength of connections and joints in consumer products like furniture or machinery

-

Assessing the durability of products that need to withstand torque or tension over long periods

-

Testing for potential failure points or weak spots in consumer products exposed to torque or tension

-

Simulating the impact of heavy load or excessive twisting forces on products during use or transport

-

Evaluating the effectiveness of design features that distribute tension or torque evenly across products

-

Testing the mechanical limits of consumer products under both static and dynamic tension or torque conditions

-

Verifying the ability of products to maintain their structural integrity under varying force conditions

-

Assessing the long-term performance of products exposed to cyclic or repetitive torque and tension

-

Testing the resistance of fasteners, adhesives, or bonding materials to torque and tension forces

-

Simulating real-life scenarios like tightening, loosening, or pulling motions to evaluate product strength

-

Testing the tension tolerance of fabrics, ropes, and other flexible materials used in consumer products

-

Assessing the strength of critical components like handles, hinges, or levers under torque and tension loads

-

Verifying that products are designed to distribute stresses evenly and avoid concentration of force

-

Testing for the durability of materials like metals, plastics, and composites under torque or tension

-

Evaluating product failure modes caused by excessive torque or tension, such as cracking, bending, or detachment

-

Simulating various stress conditions to ensure the reliability of products under everyday use and extreme conditions