Verifying the strength of connections and joints in consumer products like furniture or machinery

Verifying the Strength of Connections and Joints in Consumer Products A Crucial Service for Businesses

As a business owner in the manufacturing industry, youre likely no stranger to the importance of quality control measures. Ensuring that your products meet the highest standards of safety and durability is crucial for building customer trust and loyalty. One essential service that can help you achieve this goal is Verifying the strength of connections and joints in consumer products like furniture or machinery.

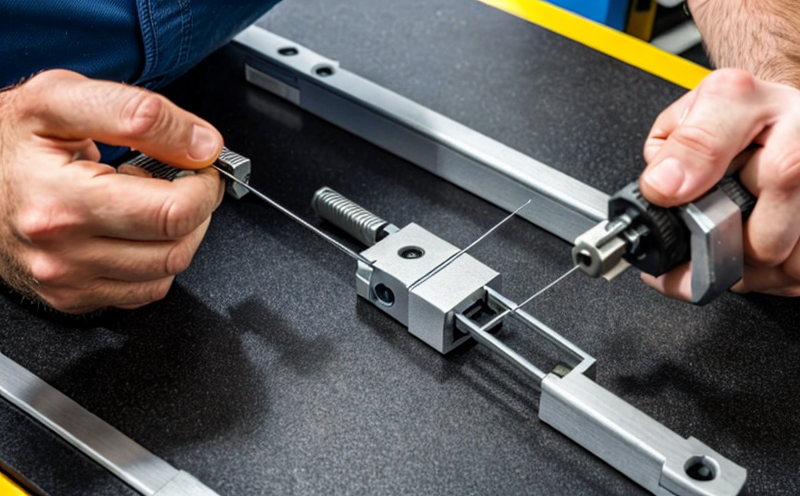

This laboratory service, offered by Eurolab, involves conducting rigorous tests to evaluate the integrity of the connections and joints within your products. By doing so, youll gain valuable insights into the performance and reliability of your goods, ultimately reducing the risk of defects, failures, and costly recalls.

In this article, well delve into the significance of Verifying the strength of connections and joints in consumer products, highlighting its numerous benefits for businesses and industries. Well also address common questions and concerns, providing you with a comprehensive understanding of this critical service.

Advantages of Verifying the Strength of Connections and Joints

Eurolabs laboratory service offers a wide range of advantages that can greatly benefit your business. Here are some key benefits to consider

Enhanced product safety By verifying the strength of connections and joints, youll ensure that your products meet or exceed relevant safety standards, reducing the risk of accidents and injuries.

Increased customer satisfaction Products with strong and reliable connections and joints tend to perform better over time, leading to higher customer satisfaction rates and reduced complaints.

Reduced warranty claims With a thorough understanding of your products structural integrity, you can minimize warranty claims and associated costs, ultimately saving your business money in the long run.

Improved brand reputation By demonstrating a commitment to quality and safety, youll enhance your brand reputation, fostering trust with customers and stakeholders alike.

Compliance with regulations Eurolabs laboratory service ensures that your products meet or exceed regulatory requirements, reducing the risk of non-compliance fines and penalties.

Key Benefits at a Glance

Cost savings Reduces warranty claims and associated costs

Increased customer satisfaction Products perform better over time, leading to higher satisfaction rates

Enhanced product safety Meets or exceeds relevant safety standards, reducing the risk of accidents and injuries

Improved brand reputation Demonstrates a commitment to quality and safety

Compliance with regulations Ensures products meet or exceed regulatory requirements

Benefits for Specific Industries

Eurolabs laboratory service is particularly beneficial for industries that rely heavily on high-quality connections and joints, such as

Furniture manufacturing Verifying the strength of connections and joints ensures that furniture meets safety standards and performs well over time.

Machinery production Ensures machinery can withstand rigorous use and harsh environments, reducing maintenance costs and downtime.

Automotive industry Evaluates the structural integrity of vehicle components, ensuring passenger safety and regulatory compliance.

QA Addressing Common Questions and Concerns

We understand that you may have questions about Eurolabs laboratory service. Here are some common queries addressed

Q What types of products can be tested?

A Our laboratory service is applicable to a wide range of consumer products, including furniture, machinery, automotive components, and more.

Q How do I prepare my product for testing?

A Please follow our guidelines on sample preparation, which will ensure your product is properly tested and evaluated.

Q What types of tests are conducted?

A Our laboratory performs various tests, including tensile strength, shear strength, fatigue testing, and more, depending on the specific requirements of your product.

Q How long does the testing process take?

A The duration of testing varies depending on the complexity of the test and the type of product. Our experts will provide a customized timeline for each project.

Q Can I get certification or documentation after testing?

A Yes, we can provide you with comprehensive reports and certificates, which can be used to support regulatory compliance and industry standards.

Conclusion

In conclusion, Verifying the strength of connections and joints in consumer products is an essential service that offers numerous benefits for businesses. By partnering with Eurolab, youll gain valuable insights into your products performance and reliability, ultimately reducing costs, improving customer satisfaction, and enhancing your brand reputation. We invite you to explore our laboratory services further, and look forward to supporting your business in its pursuit of quality and excellence.

-

Testing the ability of consumer products to withstand twisting or rotational forces without failure

-

Assessing the performance of mechanical components like screws, bolts, and fasteners under tension and torque

-

Evaluating the structural integrity of products that undergo rotational or tensile stress during use

-

Simulating real-world conditions where products are subjected to twisting, pulling, or stretching forces

-

Testing materials for their resistance to deformation when torque or tension is applied

-

Assessing the durability of products that need to withstand torque or tension over long periods

-

Testing for potential failure points or weak spots in consumer products exposed to torque or tension

-

Simulating the impact of heavy load or excessive twisting forces on products during use or transport

-

Evaluating the effectiveness of design features that distribute tension or torque evenly across products

-

Testing the mechanical limits of consumer products under both static and dynamic tension or torque conditions

-

Verifying the ability of products to maintain their structural integrity under varying force conditions

-

Assessing the long-term performance of products exposed to cyclic or repetitive torque and tension

-

Testing the resistance of fasteners, adhesives, or bonding materials to torque and tension forces

-

Simulating real-life scenarios like tightening, loosening, or pulling motions to evaluate product strength

-

Testing the tension tolerance of fabrics, ropes, and other flexible materials used in consumer products

-

Assessing the strength of critical components like handles, hinges, or levers under torque and tension loads

-

Verifying that products are designed to distribute stresses evenly and avoid concentration of force

-

Testing for the durability of materials like metals, plastics, and composites under torque or tension

-

Evaluating product failure modes caused by excessive torque or tension, such as cracking, bending, or detachment

-

Simulating various stress conditions to ensure the reliability of products under everyday use and extreme conditions