Torque and Tension Testing

The Power of Torque and Tension Testing Unlocking Efficiency and Safety in Your Business

In todays fast-paced industrial landscape, companies are constantly seeking innovative solutions to optimize their operations, ensure product quality, and mitigate risks. One laboratory service that stands out as a game-changer is Torque and Tension Testing. Provided by Eurolab, this cutting-edge testing solution has revolutionized the way businesses approach product development, manufacturing, and maintenance.

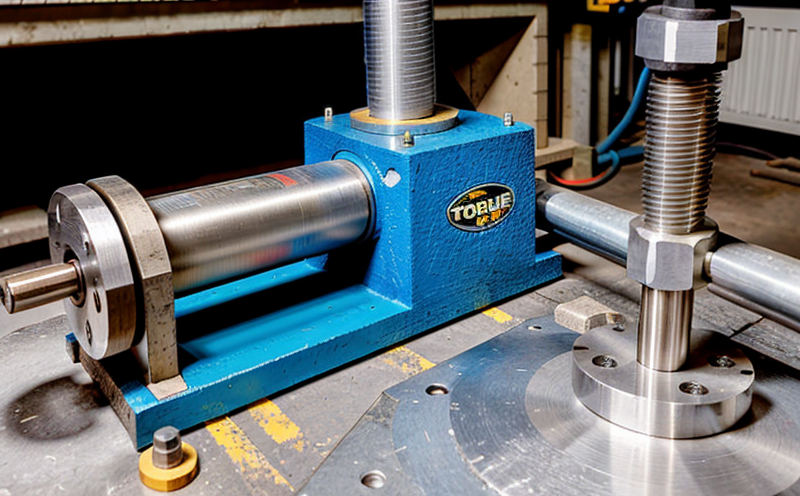

But what exactly is Torque and Tension Testing? In simple terms, its a non-destructive laboratory service that evaluates the torque (rotational force) and tension (pulling force) of materials, components, or products. This comprehensive testing enables companies to verify their products performance, reliability, and safety standards.

Why Torque and Tension Testing is Essential for Businesses

Torque and Tension Testing is a critical component of any companys quality assurance strategy. By incorporating this service into your product development cycle, you can

Ensure product compliance Meet industry-specific regulations and standards by verifying the torque and tension values of your products.

Enhance product performance Accurately test and optimize the torque and tension levels to ensure optimal performance, reduced wear, and extended lifespan.

Reduce material waste Avoid costly rework, scrap, or recalls due to faulty or under-spec materials by identifying defects early on.

Improve efficiency Streamline production processes, reduce downtime, and increase productivity through accurate testing and validation of products.

Boost customer confidence Demonstrate your commitment to product quality and safety by providing reliable data on the torque and tension levels of your products.

The Advantages of Using Torque and Tension Testing

Eurolabs Torque and Tension Testing service offers numerous benefits, including

Accurate results State-of-the-art equipment and expert technicians ensure precise measurements and reliable test data.

Flexibility Customized testing solutions to accommodate various materials, products, and industry-specific requirements.

Cost savings Avoid costly errors, rework, or recalls by identifying defects early on and optimizing production processes.

Enhanced decision-making Data-driven insights enable informed decisions on product design, development, and maintenance.

Competitive edge Stay ahead of the competition by leveraging the latest testing technology and expertise to optimize your products performance and reliability.

Frequently Asked Questions (FAQs)

Q What types of materials can be tested using Torque and Tension Testing?

A Our expert technicians can test a wide range of materials, including metals, plastics, ceramics, glass, and composites.

Q How does Torque and Tension Testing benefit my business?

A By verifying the torque and tension levels of your products, you can ensure compliance with industry standards, enhance product performance, reduce material waste, improve efficiency, and boost customer confidence.

Q What types of products require Torque and Tension Testing?

A Our service is ideal for a variety of industries, including aerospace, automotive, energy, construction, medical devices, and more. Common products that require testing include fasteners, bolts, screws, springs, cables, and wires.

Q Can I outsource my Torque and Tension Testing requirements to Eurolab?

A Yes! Our laboratory service is designed for companies seeking a reliable and efficient solution for their testing needs.

Conclusion

In todays competitive business landscape, staying ahead of the curve requires innovative solutions that drive efficiency, safety, and quality. Eurolabs Torque and Tension Testing service is an essential component of any companys product development strategy. By leveraging our state-of-the-art equipment, expert technicians, and customized testing solutions, you can unlock a wide range of benefits, from compliance and performance optimization to cost savings and competitive advantage.

Dont compromise on the quality and reliability of your products. Choose Eurolabs Torque and Tension Testing service today and experience the power of data-driven decision-making for yourself!

-

Testing the ability of consumer products to withstand twisting or rotational forces without failure

-

Assessing the performance of mechanical components like screws, bolts, and fasteners under tension and torque

-

Evaluating the structural integrity of products that undergo rotational or tensile stress during use

-

Simulating real-world conditions where products are subjected to twisting, pulling, or stretching forces

-

Testing materials for their resistance to deformation when torque or tension is applied

-

Verifying the strength of connections and joints in consumer products like furniture or machinery

-

Assessing the durability of products that need to withstand torque or tension over long periods

-

Testing for potential failure points or weak spots in consumer products exposed to torque or tension

-

Simulating the impact of heavy load or excessive twisting forces on products during use or transport

-

Evaluating the effectiveness of design features that distribute tension or torque evenly across products

-

Testing the mechanical limits of consumer products under both static and dynamic tension or torque conditions

-

Verifying the ability of products to maintain their structural integrity under varying force conditions

-

Assessing the long-term performance of products exposed to cyclic or repetitive torque and tension

-

Testing the resistance of fasteners, adhesives, or bonding materials to torque and tension forces

-

Simulating real-life scenarios like tightening, loosening, or pulling motions to evaluate product strength

-

Testing the tension tolerance of fabrics, ropes, and other flexible materials used in consumer products

-

Assessing the strength of critical components like handles, hinges, or levers under torque and tension loads

-

Verifying that products are designed to distribute stresses evenly and avoid concentration of force

-

Testing for the durability of materials like metals, plastics, and composites under torque or tension

-

Evaluating product failure modes caused by excessive torque or tension, such as cracking, bending, or detachment

-

Simulating various stress conditions to ensure the reliability of products under everyday use and extreme conditions