Assessing the thermal behavior of gearboxes under continuous load conditions

Assessing the Thermal Behavior of Gearboxes Under Continuous Load Conditions A Critical Service for Industry Leaders

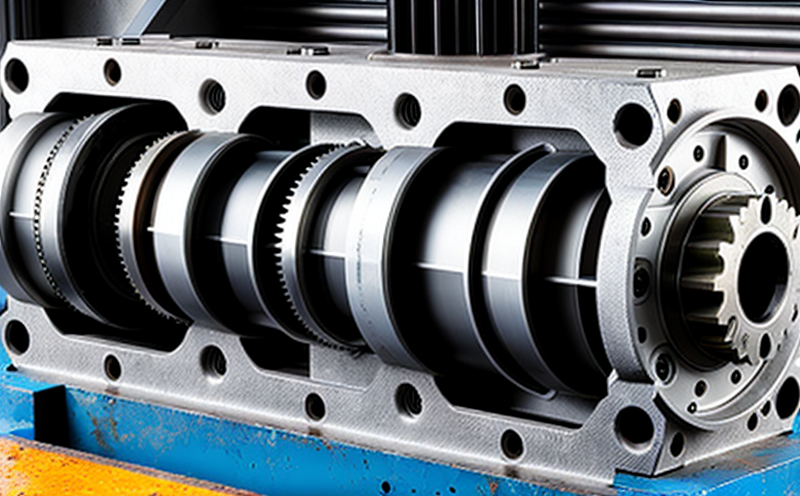

As the worlds industries continue to rely on complex machinery and equipment, ensuring their reliability and longevity has become an increasingly pressing concern. Among these concerns is the thermal behavior of gearboxes under continuous load conditions a crucial aspect that can make or break a companys bottom line. In this article, well delve into the importance of assessing the thermal behavior of gearboxes, the benefits of doing so, and how Eurolabs state-of-the-art laboratory services can help you achieve optimal performance.

What is Assessing the Thermal Behavior of Gearboxes Under Continuous Load Conditions?

In essence, assessing the thermal behavior of gearboxes under continuous load conditions involves analyzing the temperature fluctuations within a gearbox as it operates continuously. This service aims to determine how a gearbox responds to prolonged use, including its ability to dissipate heat and maintain optimal performance.

Why is Assessing Thermal Behavior Crucial for Businesses?

As companies strive to optimize their production processes, they often overlook one critical aspect the thermal behavior of their gearboxes. Neglecting this crucial factor can lead to costly consequences

Equipment Failure Continuous load conditions can cause a gearboxs components to overheat, leading to premature wear and eventual failure.

Reduced Productivity Equipment downtime due to overheating or malfunction can significantly impact production capacity.

Increased Maintenance Costs Unaddressed thermal issues can result in more frequent maintenance and repairs, eating into company profits.

Environmental Concerns Excessive heat generated by gearboxes can lead to environmental issues, such as increased energy consumption.

The Benefits of Assessing Thermal Behavior

Conducting a thorough assessment of your gearboxs thermal behavior offers numerous benefits

Improved Reliability Identifying and addressing potential overheating issues reduces the likelihood of equipment failure.

Enhanced Performance By optimizing gearboxes for continuous load conditions, companies can improve overall system efficiency.

Reduced Maintenance Costs With a deeper understanding of thermal behavior, maintenance teams can schedule repairs and replacements more effectively.

Increased Productivity Efficient gearboxes enable production facilities to operate at maximum capacity.

Compliance with Industry Standards Assessing thermal behavior ensures that your equipment meets or exceeds regulatory requirements.

How Does Eurolabs Laboratory Service Help?

Eurolabs state-of-the-art laboratory services provide industry leaders with a comprehensive assessment of their gearboxes thermal behavior. Our team of experts employ cutting-edge technology to

Monitor Temperature Fluctuations Utilizing advanced sensors and data analysis tools, we track temperature changes within the gearbox under continuous load conditions.

Analyze Heat Transfer We examine how heat is dissipated through various components, identifying areas for improvement.

Simulate Real-World Conditions Our lab environment allows us to simulate prolonged use scenarios, providing a more accurate representation of actual performance.

What Sets Eurolabs Service Apart?

At Eurolab, we pride ourselves on delivering high-quality services that exceed industry standards. Here are just a few reasons why our laboratory service stands out

Expertise Our team consists of highly trained engineers and technicians with extensive experience in gearbox analysis.

State-of-the-Art Equipment We utilize the latest technology to ensure accurate and reliable results.

Customized Solutions Our services are tailored to meet the unique needs of each client, providing actionable recommendations for improvement.

Frequently Asked Questions (FAQs)

Q What types of gearboxes can Eurolab assess?

A We assess a wide range of gearbox types, including industrial, aerospace, and automotive applications.

Q How long does the assessment process typically take?

A The duration depends on the scope of work, but most assessments are completed within 2-4 weeks.

Q What kind of data can I expect from Eurolabs service?

A We provide detailed reports, including temperature profiles, heat transfer analysis, and recommendations for improvement.

Q Can I obtain certification or compliance documentation from Eurolabs assessment?

A Yes, our reports can be used to support industry standards and regulatory requirements.

Conclusion

In todays fast-paced industrial landscape, assessing the thermal behavior of gearboxes under continuous load conditions is no longer a nicety its a necessity. By understanding your equipments performance in real-world scenarios, you can optimize production processes, reduce costs, and ensure compliance with industry regulations. Eurolabs laboratory service provides unparalleled expertise and cutting-edge technology to help you achieve these goals. Contact us today to schedule an assessment and take the first step towards optimal gearbox performance.

Note This article is provided for informational purposes only. Any reference to company names or products should not be taken as a guarantee of endorsement or affiliation.