Testing the resistance of gearbox components to wear and tear under heavy load

Testing the Resistance of Gearbox Components to Wear and Tear under Heavy Load A Crucial Laboratory Service for Businesses

In todays fast-paced industrial landscape, businesses are constantly seeking ways to optimize their equipments performance, reduce maintenance costs, and ensure seamless operations. One critical aspect that often gets overlooked is the testing of gearbox components to withstand heavy loads. This laboratory service, offered by Eurolab, plays a vital role in helping companies identify potential weaknesses in their gearboxes, thereby preventing costly breakdowns and reducing downtime.

What is Testing the Resistance of Gearbox Components to Wear and Tear under Heavy Load?

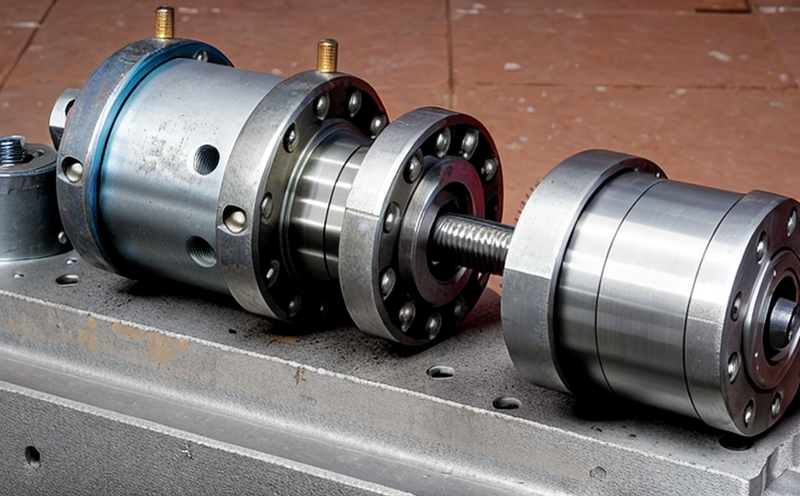

Testing the resistance of gearbox components to wear and tear under heavy load involves subjecting these critical parts to simulated conditions that mimic real-world operational pressures. This rigorous testing process evaluates the ability of gearboxes, bearings, seals, and other components to withstand extreme loads, temperatures, and vibrations without compromising their integrity.

By conducting this laboratory service, Eurolabs team of experts can help businesses

Extend Equipment Lifespan By identifying potential wear points early on, companies can take proactive measures to replace or repair components before they cause catastrophic failures.

Reduce Maintenance Costs Regular testing helps prevent costly repairs and replacements by pinpointing areas that require attention, allowing for targeted maintenance.

Minimize Downtime With a thorough understanding of their equipments limitations, businesses can schedule maintenance during planned shutdowns, reducing unexpected downtime and associated losses.

Advantages of Using Testing the Resistance of Gearbox Components to Wear and Tear under Heavy Load

Eurolabs laboratory service offers numerous benefits that justify its importance in modern industrial operations. Key advantages include

Improved Reliability By simulating real-world conditions, companies can be assured of their equipments reliability and performance.

Enhanced Safety Regular testing helps prevent accidents by identifying potential risks associated with worn or damaged components.

Increased Efficiency With optimized gearboxes and bearings, businesses can enjoy improved fuel efficiency, reduced energy consumption, and increased productivity.

Compliance with Regulations Conducting regular testing ensures companies adhere to industry standards and regulatory requirements.

Key Benefits

Accurate Component Testing Eurolabs state-of-the-art equipment enables precise simulation of various operational conditions, ensuring accurate results.

Rapid Turnaround Times Our experienced team delivers prompt test reports, allowing businesses to schedule maintenance or repairs in a timely manner.

Customized Solutions We offer tailored testing packages to meet specific business needs and budget constraints.

Expert Analysis Eurolabs team provides comprehensive analysis of test results, offering actionable recommendations for improvement.

QA Section

Q What types of gearboxes can be tested?

A Our laboratory service caters to a wide range of gearbox types, including industrial, automotive, aerospace, and marine gearboxes.

Q How long does the testing process take?

A Testing times vary depending on the type of test and equipment being used. On average, results are available within 24-72 hours.

Q Can I request a customized testing package?

A Yes! Eurolab offers flexible packages tailored to your specific needs and budget. Simply contact us to discuss your requirements.

Q What kind of documentation do I receive after the test?

A We provide comprehensive, detailed reports outlining test results, recommendations for improvement, and any necessary maintenance or repairs.

Conclusion

In todays fast-paced industrial environment, businesses must prioritize equipment reliability, safety, and efficiency. Eurolabs laboratory service for testing gearbox components to wear and tear under heavy load plays a vital role in helping companies achieve these goals. By conducting this critical test, businesses can identify potential weaknesses, extend equipment lifespan, reduce maintenance costs, and minimize downtime.

Dont let subpar gearboxes compromise your operations. Contact Eurolab today to schedule your Testing the Resistance of Gearbox Components to Wear and Tear under Heavy Load laboratory service and take the first step towards optimized performance, reduced costs, and enhanced reliability.

Get started with Eurolabs testing services

Our dedicated team is ready to help you optimize your equipments performance. Fill out our online form to request a customized testing package or learn more about how we can support your business.