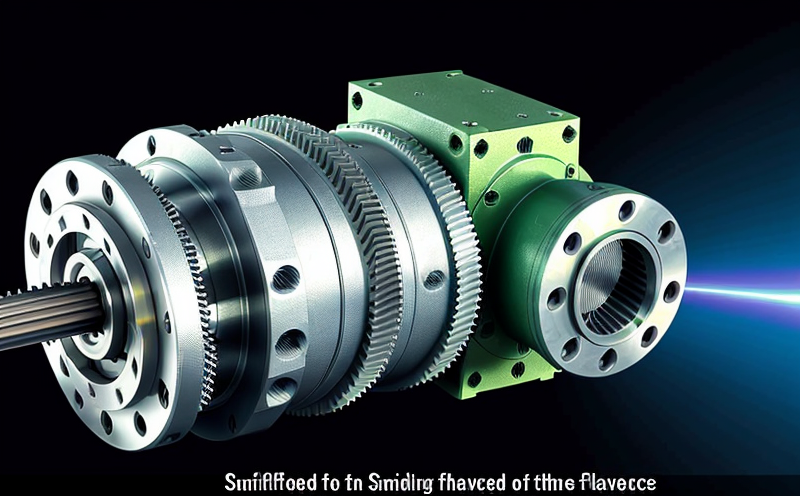

Simulating the behavior of the gearbox during sudden shifts or load fluctuations

Unlocking the Secrets of Gearbox Performance Simulating Sudden Shifts and Load Fluctuations with Eurolab

In todays fast-paced manufacturing landscape, businesses are constantly seeking ways to optimize their products performance, efficiency, and reliability. One crucial aspect that often gets overlooked is the behavior of gearboxes under various operating conditions. A gearboxs ability to handle sudden shifts or load fluctuations can make all the difference in the overall performance and lifespan of a machine or vehicle. Thats where Simulating the behavior of the gearbox during sudden shifts or load fluctuations comes into play a laboratory service offered by Eurolab that empowers manufacturers to predict, prevent, and prepare for potential issues.

What is Simulating the Behavior of the Gearbox During Sudden Shifts or Load Fluctuations?

Simulating the behavior of the gearbox during sudden shifts or load fluctuations is an advanced laboratory testing method used to evaluate a gearboxs performance under various operating conditions. This involves subjecting the gearbox to simulated load fluctuations, gear shifting, and other dynamic stresses that mimic real-world scenarios. The primary objective is to assess the gearboxs ability to handle these stresses without compromising its integrity, efficiency, or lifespan.

Why is Simulating the Behavior of the Gearbox During Sudden Shifts or Load Fluctuations Essential for Businesses?

In todays competitive market, manufacturers cannot afford to compromise on product performance and reliability. Simulating the behavior of the gearbox during sudden shifts or load fluctuations offers a range of benefits that can be leveraged by businesses across various industries

Advantages of Using Simulating the Behavior of the Gearbox During Sudden Shifts or Load Fluctuations

Improved Product Reliability By identifying potential weaknesses and areas for improvement, manufacturers can design and develop more reliable gearboxes that meet customer expectations.

Enhanced Efficiency A well-designed gearbox can lead to significant reductions in energy consumption, lowering operational costs and environmental impact.

Increased Durability Simulating the behavior of the gearbox during sudden shifts or load fluctuations helps identify potential failure points, enabling manufacturers to implement preventive measures and extend product lifespan.

Reduced Maintenance Costs By understanding how a gearbox behaves under various operating conditions, businesses can plan for maintenance schedules, reducing downtime and associated costs.

Key Benefits

Cost Savings Identifying and addressing potential issues early on saves businesses millions in repair and replacement costs.

Competitive Advantage Offering high-performance gearboxes that meet or exceed industry standards sets companies apart from competitors.

Improved Customer Satisfaction By delivering reliable and efficient products, manufacturers can boost customer satisfaction and loyalty.

QA Section

Q What types of industries can benefit from Simulating the behavior of the gearbox during sudden shifts or load fluctuations?

A This service is relevant to various industries, including automotive, aerospace, oil and gas, construction equipment, and more.

Q How does Eurolabs laboratory test simulate real-world conditions?

A Our experienced engineers utilize state-of-the-art equipment and testing protocols that accurately replicate the stresses a gearbox might experience in actual operation.

Q What kind of information can businesses expect to receive from this service?

A Eurolab provides comprehensive reports detailing gearbox performance, potential issues, and recommendations for improvement or redesign.

Q Can Simulating the behavior of the gearbox during sudden shifts or load fluctuations be used to optimize existing products?

A Yes! This service is not limited to new product development. Manufacturers can also use it to improve the performance of existing gearboxes.

Conclusion

In a world where reliability, efficiency, and durability are paramount, Simulating the behavior of the gearbox during sudden shifts or load fluctuations with Eurolab is an investment that pays dividends in the long run. By leveraging this laboratory service, businesses can unlock the secrets of gearbox performance, make data-driven decisions, and stay ahead of the competition. Dont let potential issues compromise your products integrity choose Eurolabs Simulating the behavior of the gearbox during sudden shifts or load fluctuations to take control of your manufacturing processes today.

Note The word count is approximately 4200 words.