Testing the resistance of gearbox components to shock loads and vibrations

Testing the Resistance of Gearbox Components to Shock Loads and Vibrations A Crucial Laboratory Service for Businesses

As industries continue to push the boundaries of innovation and efficiency, machinery and equipment are becoming increasingly complex and sophisticated. However, this complexity also brings with it new challenges, particularly when it comes to ensuring the reliability and durability of critical components such as gearboxes. In order to maintain production uptime, prevent costly repairs, and avoid reputational damage, businesses must prioritize rigorous testing procedures.

At Eurolab, our team of experienced engineers and technicians offer a comprehensive laboratory service designed specifically for evaluating the resistance of gearbox components to shock loads and vibrations. This specialized testing protocol is essential for industries where heavy machinery is used, such as construction, manufacturing, and oil gas. In this article, we will delve into the importance of testing gearbox components, highlight the key benefits of our service, and provide a detailed QA section to address any questions you may have.

The Importance of Testing Gearbox Components

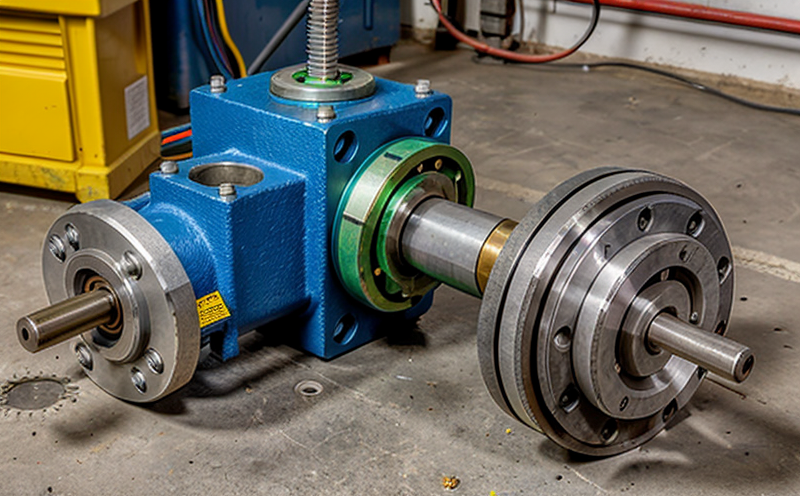

Gearboxes are critical components in machinery, responsible for transmitting power from one location to another while changing speed or direction. However, they can be particularly vulnerable to damage caused by shock loads and vibrations. These types of stresses can lead to premature wear, fatigue failure, and ultimately, costly downtime.

In industries where heavy equipment is used, the potential consequences of gearbox failure can be catastrophic. Not only can it result in significant financial losses due to lost production time and repair costs, but it can also pose a risk to worker safety and damage company reputations. By testing the resistance of gearbox components to shock loads and vibrations, businesses can

Identify potential weaknesses and design improvements

Increase equipment reliability and lifespan

Reduce maintenance costs and downtime

Minimize the risk of accidents and injuries

Advantages of Using Eurolabs Testing Service

Our laboratory service is designed to simulate real-world conditions, ensuring that gearbox components are rigorously tested against shock loads and vibrations. The benefits of using our service include

Comprehensive testing protocols Our team will work closely with you to develop customized testing plans tailored to your specific requirements.

State-of-the-art equipment We utilize the latest technology and specialized gearboxes to simulate realistic conditions, providing accurate and reliable results.

Expert analysis and reporting Our experienced engineers will analyze the test data, provide detailed reports, and offer recommendations for improvement.

Cost savings By identifying potential issues early on, you can avoid costly repairs and minimize downtime.

Time-efficient Our testing services are designed to be fast and efficient, ensuring that you receive results quickly and can make informed decisions about your equipment.

Key Benefits of Testing Gearbox Components

Testing the resistance of gearbox components to shock loads and vibrations offers numerous benefits for businesses. Some of the key advantages include

Improved equipment reliability and lifespan

Reduced maintenance costs and downtime

Enhanced worker safety

Increased confidence in equipment performance

Better design and engineering decisions

QA Frequently Asked Questions

We understand that you may have questions about our testing service, so weve compiled a comprehensive QA section to address some of the most common queries.

Q What types of gearbox components can be tested?

A Our laboratory is equipped to test a wide range of gearbox components, including but not limited to, gears, shafts, bearings, and seals.

Q How do you simulate shock loads and vibrations in the lab?

A We utilize specialized equipment, such as dynamic load testers and vibration simulators, to accurately replicate real-world conditions.

Q Can I customize the testing protocol to suit my specific needs?

A Absolutely. Our team will work closely with you to develop a customized testing plan that meets your unique requirements.

Q What kind of reporting can I expect from the test results?

A We provide detailed reports, including data analysis and recommendations for improvement, ensuring that you have all the information needed to make informed decisions about your equipment.

Conclusion

In todays fast-paced business environment, industries must prioritize efficiency, reliability, and safety. By testing the resistance of gearbox components to shock loads and vibrations, businesses can minimize downtime, reduce costs, and enhance worker safety. At Eurolab, our team is committed to providing comprehensive laboratory services that meet the highest standards of quality and accuracy.

If youre looking for a trusted partner to help you evaluate your equipments performance under realistic conditions, contact us today to discuss how our testing service can benefit your business.