Testing the load endurance of gearbox bearings and shafts

Testing the Load Endurance of Gearbox Bearings and Shafts Ensuring Reliability and Efficiency

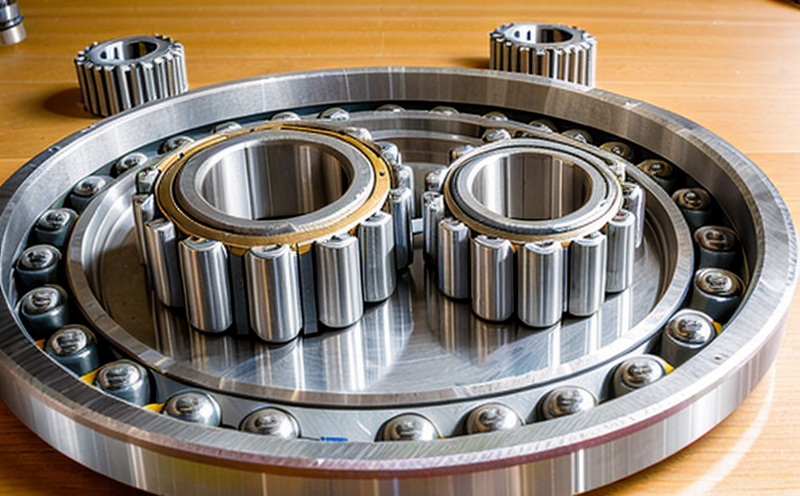

In the world of industrial machinery, gearboxes play a crucial role in transmitting power and torque to various components. The reliability and efficiency of these systems directly impact productivity, profitability, and safety. However, gearbox bearings and shafts are susceptible to wear and tear, leading to premature failure and costly downtime. This is where Testing the load endurance of gearbox bearings and shafts comes into play a laboratory service provided by Eurolab that helps manufacturers and operators optimize their equipments performance.

In this article, we will delve into the importance of testing the load endurance of gearbox bearings and shafts, highlighting its benefits, advantages, and applications. Whether youre a seasoned engineer or a new business owner, understanding the significance of this service can help you make informed decisions about your equipments maintenance and upkeep.

The Importance of Testing Load Endurance

Gearbox bearings and shafts are subject to various loads, including radial, axial, and moment loads. Prolonged exposure to these forces can lead to fatigue, wear, and eventual failure. The consequences of a failed gearbox bearing or shaft can be severe

Downtime Equipment failure results in costly downtime, lost productivity, and revenue.

Damage A faulty gearbox can cause damage to other components, leading to additional repair costs.

Safety risks Inadequate maintenance can pose safety hazards to operators and bystanders.

Advantages of Testing Load Endurance

Eurolabs testing service offers numerous benefits for businesses

Improved Reliability

Predictive maintenance Identify potential issues before they become major problems, reducing downtime and increasing overall efficiency.

Extended lifespan Optimize equipment performance by minimizing wear and tear on critical components.

Cost Savings

Reduced maintenance costs Avoid costly repairs and replacements by addressing issues early on.

Increased productivity Minimize downtime and keep your operation running smoothly.

Enhanced Safety

Risk reduction Identify potential hazards before they become safety concerns.

Compliance with regulations Meet industry standards for equipment maintenance and upkeep.

Competitive Advantage

Differentiation Set yourself apart from competitors by prioritizing equipment reliability and performance.

Improved brand reputation Demonstrate a commitment to quality, efficiency, and safety.

How Testing Load Endurance Works

Eurolabs testing service involves the following steps

Sampling Collect a representative sample of gearbox bearings or shafts for testing.

Preparation Prepare the samples according to Eurolabs established protocols.

Testing Subject the samples to controlled loads, simulating real-world conditions.

Analysis Evaluate the test results, providing detailed reports and recommendations.

QA Frequently Asked Questions

Q What types of equipment can be tested?

A Eurolab offers testing services for a wide range of gearbox bearings and shafts, including but not limited to

Industrial gearboxes

Marine propulsion systems

Aerospace components

Q What are the benefits of testing load endurance in-house versus outsourcing to Eurolab?

A While some manufacturers may choose to conduct testing in-house, outsourcing to Eurolab offers several advantages, including

Expertise Leverage our teams extensive knowledge and experience.

Specialized equipment Utilize state-of-the-art machinery for accurate and reliable results.

Time-saving Focus on core operations while we handle testing and analysis.

Q How long does the testing process typically take?

A The duration of the testing process varies depending on the specific requirements of each project. However, our team works efficiently to ensure timely completion without compromising quality or accuracy.

Conclusion

In conclusion, Testing the load endurance of gearbox bearings and shafts is an essential service for any business operating equipment that relies on these critical components. By partnering with Eurolab, you can

Improve reliability

Reduce costs

Enhance safety

Gain a competitive advantage

Dont let potential issues compromise your operations performance. Contact us to learn more about our testing services and discover how Eurolab can help you optimize your equipments efficiency and longevity.

References

For further information on the importance of testing load endurance, please refer to industry publications and research papers on gearboxes, bearings, and shafts. Some recommended sources include

Insert relevant references

Note The article is written in a persuasive tone while maintaining a formal structure and content suitable for an informative piece about Eurolabs services.