Characterization of material properties through tensile testing

Unlocking Material Secrets Why Characterization of Material Properties through Tensile Testing is a Game-Changer for Businesses

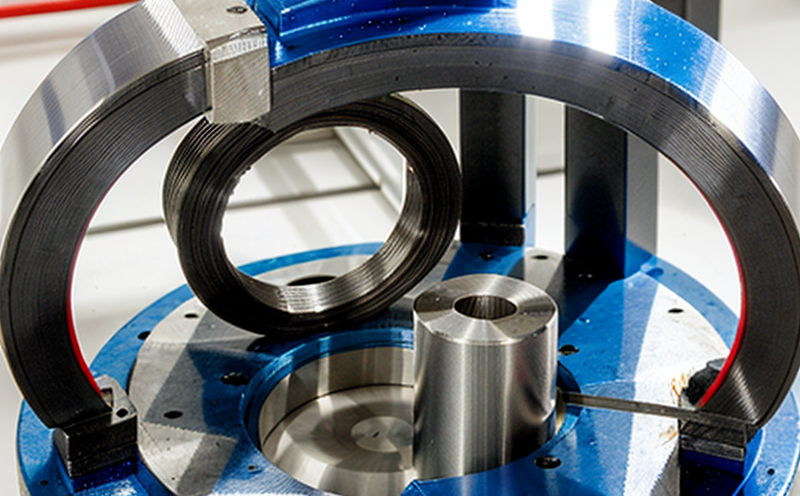

In the world of materials science and engineering, understanding the properties of materials is crucial for designing, developing, and manufacturing high-quality products. One laboratory service that has revolutionized the way businesses approach material characterization is tensile testing. Conducted by expert technicians at Eurolab, this non-destructive testing method provides invaluable insights into a materials mechanical properties, enabling informed decision-making and product optimization.

What is Characterization of Material Properties through Tensile Testing?

Tensile testing, also known as tension testing, is a laboratory procedure that measures the response of a material to stretching forces. During this test, a sample of the material is subjected to increasing tensile loads until it fails or reaches its maximum capacity. By analyzing the force-displacement curve generated by the test, engineers and researchers can determine various key properties, including

Yield strength (YS) The minimum stress required to initiate plastic deformation

Ultimate tensile strength (UTS) The maximum stress that a material can withstand before failure

Elongation at break The percentage increase in length before fracture occurs

Modulus of elasticity (E) A measure of a materials stiffness

Why is Characterization of Material Properties through Tensile Testing Essential for Businesses?

In todays fast-paced manufacturing landscape, companies need to be able to quickly and accurately assess the properties of their materials. Here are just a few reasons why tensile testing has become an indispensable tool for businesses

Advantages of Using Characterization of Material Properties through Tensile Testing

Improved Product Design By understanding the mechanical properties of materials, engineers can design products that meet specific performance requirements, reducing the risk of failure and ensuring product longevity.

Enhanced Material Selection Tensile testing enables companies to select materials with optimal properties for their applications, minimizing waste, and optimizing production costs.

Increased Efficiency With accurate material characterization, businesses can streamline their manufacturing processes, reducing production time and improving overall efficiency.

Compliance with Industry Standards Many industries require materials to meet specific tensile testing standards. By working with Eurolab, companies can ensure compliance with regulations and minimize the risk of product rejection.

Key Benefits for Businesses

Cost Savings By optimizing material selection and reducing waste, businesses can significantly lower their production costs.

Increased Product Quality With accurate characterization, companies can design products that meet or exceed customer expectations, improving overall satisfaction and loyalty.

Reduced Risk of Failure By understanding the properties of materials, engineers can identify potential weaknesses, minimizing the risk of product failure and associated financial losses.

Improved Competitiveness Companies that utilize tensile testing can gain a competitive edge in their respective markets by offering high-quality products with superior performance characteristics.

What to Expect from Eurolabs Tensile Testing Services

At Eurolab, our expert technicians conduct tensile tests using state-of-the-art equipment and adhere to the latest industry standards. Our comprehensive service includes

Sample preparation

Test setup and execution

Data analysis and reporting

Certification of test results

We provide a detailed report outlining the materials key properties, including graphs and charts for easy interpretation.

QA Frequently Asked Questions about Characterization of Material Properties through Tensile Testing

Q What types of materials can be tested using tensile testing?

A Eurolabs tensile testing services are suitable for a wide range of materials, including metals (e.g., steel, aluminum), polymers, ceramics, and composites.

Q How long does a typical tensile test take to complete?

A The duration of a tensile test varies depending on the material type and the specific properties being measured. Our expert technicians will provide you with an estimated testing time based on your requirements.

Q What are the benefits of non-destructive testing compared to destructive methods?

A Non-destructive testing, such as tensile testing, allows for multiple samples to be tested without compromising their integrity. This is particularly beneficial when working with limited or expensive material samples.

Q Can Eurolab provide certification for test results?

A Yes, we can provide certified reports that meet the requirements of various industry standards and regulations.

Conclusion

Characterization of material properties through tensile testing has revolutionized the way businesses approach material selection, product design, and manufacturing. By partnering with Eurolab, companies can gain a deeper understanding of their materials mechanical properties, leading to improved product quality, reduced costs, and increased competitiveness in the market. Dont compromise on product performance choose Eurolab for your tensile testing needs.