Fatigue testing and its effect on tensile strength

Unlocking Material Performance The Crucial Role of Fatigue Testing in Ensuring Tensile Strength

In todays fast-paced industrial landscape, manufacturers and quality control professionals face an array of challenges that can impact the reliability and lifespan of their products. One critical factor that can significantly affect a materials performance is fatigue the progressive degradation of material properties over time due to cyclic loading. Fatigue testing has become a cornerstone in ensuring the tensile strength and durability of materials, and for good reason.

As a leading laboratory service provider, Eurolab offers state-of-the-art fatigue testing solutions that help businesses safeguard their products against the adverse effects of fatigue. In this comprehensive article, well delve into the world of fatigue testing, exploring its significance in determining tensile strength and why its an essential tool for any industry.

What is Fatigue Testing?

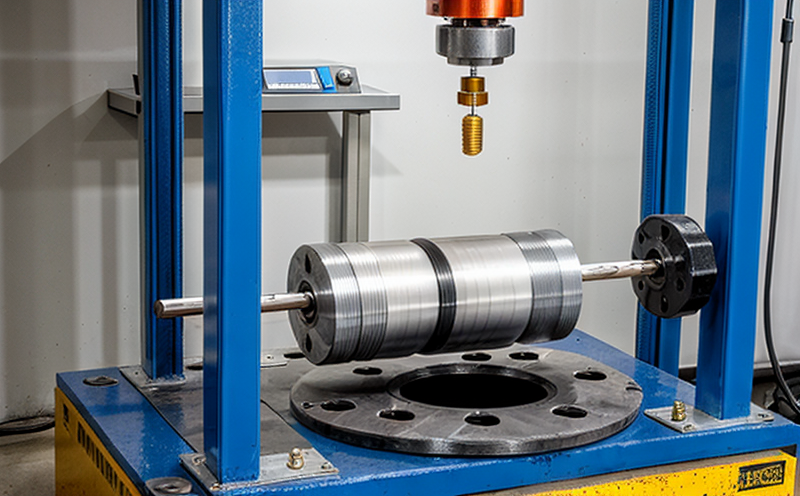

Fatigue testing involves subjecting a material to repeated loading and unloading cycles to simulate real-world conditions. This process helps determine how a material will perform under cyclic stresses, revealing potential weaknesses or vulnerabilities that could lead to premature failure. By conducting fatigue tests, manufacturers can gain valuable insights into their materials behavior under various stress regimes, ensuring optimal performance and minimizing the risk of catastrophic failures.

The Impact of Fatigue on Tensile Strength

Tensile strength is a fundamental material property that determines an objects ability to withstand external forces without deforming or breaking. However, repeated loading and unloading cycles can compromise tensile strength, leading to reduced material durability and increased susceptibility to failure. By conducting fatigue tests, manufacturers can assess the effects of cyclic loading on their materials tensile strength.

Advantages of Fatigue Testing

Eurolabs expert team is dedicated to delivering comprehensive fatigue testing solutions that cater to various industries and applications. The benefits of fatigue testing are numerous

Ensures Material Reliability By simulating real-world conditions, fatigue testing guarantees material reliability, reducing the risk of premature failure.

Optimizes Material Selection Fatigue tests help manufacturers choose the most suitable materials for their products, ensuring optimal performance and longevity.

Reduces Warranty Costs Conducting fatigue tests can significantly minimize warranty costs by identifying potential weaknesses before they become a major issue.

Enhances Product Safety By evaluating material behavior under cyclic stresses, businesses can ensure product safety and compliance with industry regulations.

Supports Research and Development Fatigue testing is an invaluable tool for researchers and developers seeking to improve material properties and performance.

Key Benefits of Using Eurolabs Fatigue Testing Services

Our comprehensive fatigue testing solutions come with a range of benefits, including

Accurate Results Our state-of-the-art equipment and expert personnel ensure accurate results, providing you with valuable insights into your materials behavior.

Cost-Effective By identifying potential weaknesses early on, businesses can reduce warranty costs and minimize the risk of costly repairs or replacements.

Time-Efficient Eurolabs fatigue testing services are designed to meet your unique needs, ensuring timely results that wont disrupt your production schedule.

QA Section

Here are some frequently asked questions about fatigue testing and its effect on tensile strength

Q What is the significance of fatigue testing in determining tensile strength?

A Fatigue testing plays a crucial role in assessing material durability under cyclic stresses, ensuring optimal performance and minimizing the risk of premature failure.

Q How can I ensure my materials are suitable for their intended applications?

A Conducting fatigue tests with Eurolabs expert team will provide you with valuable insights into your materials behavior under various stress regimes, enabling you to make informed decisions about material selection.

Q What types of industries can benefit from fatigue testing?

A Fatigue testing is a versatile tool that caters to various industries and applications, including aerospace, automotive, construction, medical devices, and more.

Conclusion

In conclusion, fatigue testing is an essential service for businesses seeking to ensure the reliability and performance of their products. By simulating real-world conditions, Eurolabs expert team can help manufacturers identify potential weaknesses and vulnerabilities that could impact tensile strength. With our comprehensive fatigue testing solutions, youll gain valuable insights into your materials behavior under cyclic stresses, ensuring optimal performance and minimizing the risk of premature failure.

Join forces with Eurolab today to unlock material performance and take your business to new heights!