Tensile testing for thin materials and coatings

The Importance of Tensile Testing for Thin Materials and Coatings Ensuring Quality and Reliability

In the world of materials science and engineering, thin materials and coatings play a crucial role in various industries such as aerospace, automotive, energy, and electronics. These materials are used to enhance performance, reduce weight, and improve durability. However, their thin nature makes them prone to failure under tensile stress, which can lead to catastrophic consequences.

To ensure the quality and reliability of these materials, it is essential to conduct Tensile testing for thin materials and coatings. At Eurolab, we offer a comprehensive laboratory service that provides accurate and reliable results, enabling businesses to make informed decisions about their products.

What is Tensile Testing for Thin Materials and Coatings?

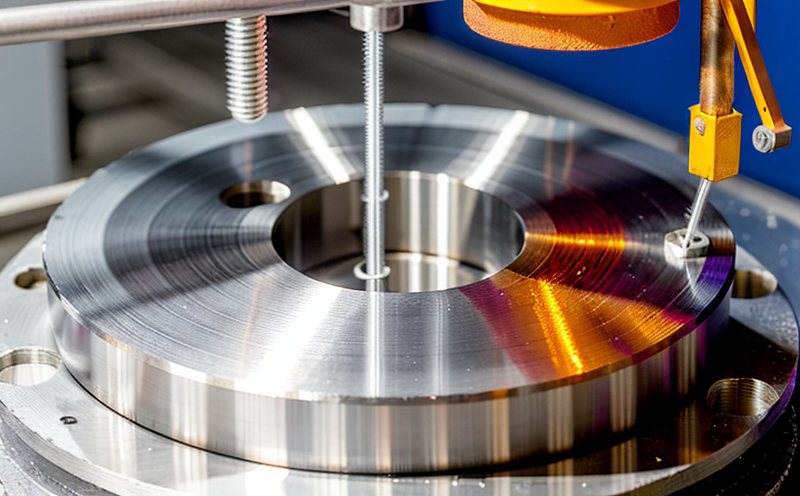

Tensile testing, also known as tension testing, is a widely used mechanical test method that evaluates the strength and durability of materials by subjecting them to tensile stress. In the context of thin materials and coatings, this test involves applying a controlled force to the material until it fails or reaches its maximum strength.

Our Tensile testing for thin materials and coatings service uses advanced equipment and techniques to simulate real-world conditions, providing accurate and reliable results. This information is crucial for businesses looking to ensure the quality and reliability of their products, particularly in critical applications such as aerospace and automotive.

Why is Tensile Testing for Thin Materials and Coatings Essential?

Conducting Tensile testing on thin materials and coatings is essential for several reasons

Ensures Quality and Reliability By subjecting materials to tensile stress, businesses can identify potential weaknesses and ensure that their products meet the required standards.

Reduces Risk of Failure Thin materials and coatings are prone to failure under tensile stress. Conducting Tensile testing helps businesses identify these risks and take corrective action.

Improves Durability By understanding the strength and durability of thin materials and coatings, businesses can optimize their designs and improve product performance.

Enhances Safety In critical applications such as aerospace and automotive, material failure can have catastrophic consequences. Tensile testing ensures that materials meet safety standards.

Benefits of Tensile Testing for Thin Materials and Coatings

Our Tensile testing service offers numerous benefits to businesses, including

Accurate Results Our advanced equipment and techniques ensure accurate and reliable results.

Cost-Effective By identifying potential weaknesses early on, businesses can reduce costs associated with material failure.

Improved Product Performance Understanding the strength and durability of thin materials and coatings enables businesses to optimize their designs and improve product performance.

Compliance with Regulations Our Tensile testing service ensures that products meet regulatory requirements and industry standards.

QA Frequently Asked Questions about Tensile Testing for Thin Materials and Coatings

Q1 What is the purpose of Tensile testing for thin materials and coatings?

A1 The primary purpose of Tensile testing is to evaluate the strength and durability of thin materials and coatings by subjecting them to tensile stress.

Q2 How does Tensile testing help businesses ensure quality and reliability?

A2 Conducting Tensile testing helps businesses identify potential weaknesses in thin materials and coatings, ensuring that their products meet required standards and reducing the risk of failure.

Q3 What types of industries benefit from Tensile testing for thin materials and coatings?

A3 Various industries such as aerospace, automotive, energy, and electronics benefit from Tensile testing for thin materials and coatings due to their reliance on these materials for optimal performance.

Q4 How does Eurolabs Tensile testing service ensure accurate results?

A4 Our advanced equipment and techniques ensure accurate and reliable results, providing businesses with confidence in their product quality and reliability.

Conclusion

Tensile testing for thin materials and coatings is a critical laboratory service that ensures the quality and reliability of products. At Eurolab, we offer a comprehensive Tensile testing service using advanced equipment and techniques to provide accurate and reliable results. By understanding the strength and durability of these materials, businesses can optimize their designs, reduce costs associated with material failure, and improve product performance.

Dont let thin materials and coatings compromise your products quality and reliability. Trust Eurolab for Tensile testing that meets industry standards and regulatory requirements. Contact us today to learn more about our laboratory services and how we can help you ensure the best possible outcome for your products.