Tensile testing for aluminum alloys

Unlock the Secrets of Aluminum Alloys Understanding Tensile Testing

As industries continue to push the boundaries of innovation and efficiency, the need for high-performance materials has never been more pressing. Among the multitude of metals used in various applications, aluminum alloys stand out for their exceptional strength-to-weight ratio, corrosion resistance, and recyclability. However, like any material, aluminum alloys are not immune to defects or variability in properties. This is where Tensile testing comes into play a crucial laboratory service that helps businesses ensure the quality and reliability of their materials.

What is Tensile Testing for Aluminum Alloys?

Tensile testing is a widely recognized mechanical test used to evaluate the tensile strength, yield strength, elongation at break, and other essential properties of aluminum alloys. This non-destructive test involves applying a gradually increasing load until the sample fails or breaks apart. The data collected from this test provides valuable insights into the materials behavior under stress, allowing engineers and manufacturers to optimize their designs, predict performance, and minimize the risk of material failure.

Why is Tensile Testing Essential for Businesses?

Tensile testing is a critical step in ensuring the quality and reliability of aluminum alloys used in various industries. Here are some key reasons why businesses should prioritize this laboratory service

Improved Material Selection By understanding the tensile properties of aluminum alloys, manufacturers can make informed decisions about which materials to use for specific applications.

Enhanced Product Performance Tensile testing helps engineers design and develop products that meet or exceed performance expectations, reducing the likelihood of material failure and associated costs.

Compliance with Industry Standards Many industries, such as aerospace, automotive, and construction, have strict regulations regarding material properties. Tensile testing ensures compliance with these standards, minimizing the risk of product rejection or recall.

Key Benefits of Tensile Testing for Aluminum Alloys

Here are some key benefits of using Tensile testing for aluminum alloys

Material Optimization By analyzing tensile properties, manufacturers can optimize material composition, reducing production costs and improving overall efficiency.

Predictive Maintenance Regular Tensile testing allows businesses to identify potential issues before they become major problems, reducing downtime and associated costs.

Improved Quality Control This laboratory service enables manufacturers to monitor material quality in real-time, ensuring that products meet or exceed specifications.

How Does Tensile Testing Work?

The Tensile testing process involves the following steps

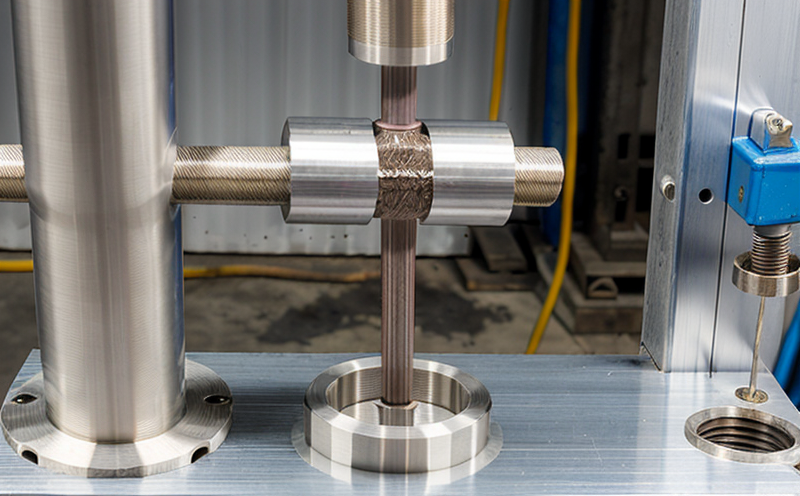

Sample preparation The aluminum alloy sample is carefully prepared for testing by cutting it to the required size and cleaning it to prevent contamination.

Load application A controlled load is applied to the sample using a tensiometer, which gradually increases until the material fails or breaks apart.

Data collection The data collected from this test includes tensile strength, yield strength, elongation at break, and other essential properties.

Frequently Asked Questions

Here are some common questions about Tensile testing for aluminum alloys

Q What is the purpose of Tensile testing?

A Tensile testing helps businesses ensure the quality and reliability of their materials by evaluating tensile strength, yield strength, elongation at break, and other essential properties.

Q How does Tensile testing benefit manufacturers?

A Regular Tensile testing allows manufacturers to optimize material composition, reduce production costs, and improve overall efficiency.

Q What are the benefits of using Tensile testing for aluminum alloys?

A The key benefits of using Tensile testing for aluminum alloys include improved material selection, enhanced product performance, compliance with industry standards, and predictive maintenance.

Why Choose Eurolab for Your Tensile Testing Needs?

At Eurolab, we pride ourselves on providing accurate and reliable laboratory services to ensure the quality and reliability of your materials. Our team of experienced engineers and technicians use state-of-the-art equipment to provide comprehensive results that meet or exceed industry standards.

Conclusion

Tensile testing is a critical step in ensuring the quality and reliability of aluminum alloys used in various industries. By understanding the tensile properties of these materials, businesses can optimize their designs, predict performance, and minimize the risk of material failure. At Eurolab, we are committed to providing accurate and reliable laboratory services that meet or exceed industry standards. Contact us today to learn more about how Tensile testing can benefit your business.

Insert Call-to-Action button Learn More

Sources

American Society for Testing and Materials (ASTM) Standard Test Methods for Tension Testing of Metallic Materials

International Organization for Standardization (ISO) ISO 68922019(en) - Metallic materials Tensile testing at ambient temperature