Innovations in tensile strength measurement techniques

Innovations in Tensile Strength Measurement Techniques Unlocking the Secrets of Materials Performance

As industries continue to push the boundaries of innovation and advancement, the demand for high-quality materials with exceptional tensile strength has never been greater. In todays competitive market, businesses must be able to trust the reliability and accuracy of their materials properties in order to ensure the success of their products and projects. This is where Eurolab comes in a leading laboratory service provider specializing in Innovations in Tensile Strength Measurement Techniques.

At Eurolab, we understand that precise tensile strength measurement is crucial for businesses operating in various sectors, including construction, aerospace, automotive, and more. Our state-of-the-art facilities and cutting-edge technology enable us to provide unparalleled accuracy and reliability in our measurements, empowering our clients to make informed decisions about their materials properties.

What are Innovations in Tensile Strength Measurement Techniques?

Innovations in tensile strength measurement techniques refer to the advanced methods used to determine the maximum stress a material can withstand before failing. This critical property is essential for ensuring the structural integrity and performance of various materials, including metals, plastics, fibers, and composites.

Our team at Eurolab employs a range of innovative techniques, including

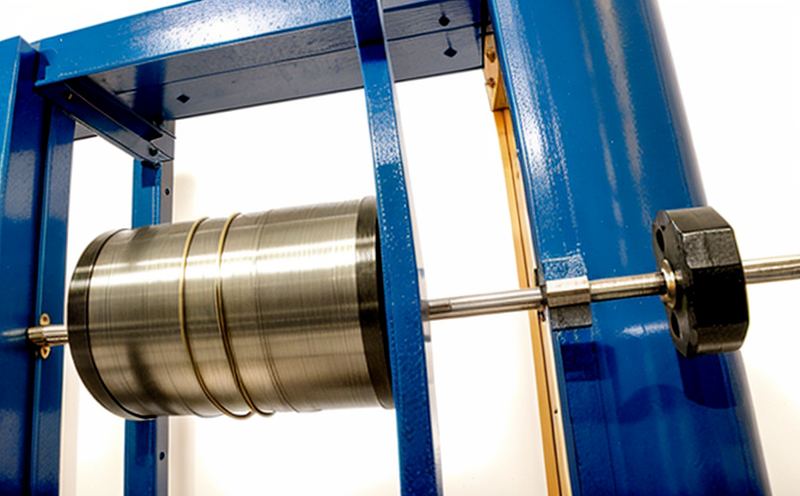

Advanced Mechanical Testing Our high-precision mechanical testing equipment ensures accurate and reliable measurements of tensile strength.

Digital Image Correlation (DIC) This non-contact technique uses cameras and software to measure deformations and stresses in materials under load.

Nanoindentation A highly sensitive method for measuring the indentation hardness and modulus of materials on a nanoscale.

The Importance of Tensile Strength Measurement

Tensile strength measurement is critical for various applications, including

Ensuring material safety and reliability

Predicting material behavior under stress and strain

Optimizing material properties for specific uses

Reducing the risk of material failure

Advantages of Using Innovations in Tensile Strength Measurement Techniques

Eurolabs expertise in Innovations in tensile strength measurement techniques offers numerous benefits to our clients, including

Accurate Material Property Data

Gain precise and reliable information about your materials tensile strength

Trust the accuracy of your measurements with our state-of-the-art equipment and expert analysis

Enhanced Material Selection

Make informed decisions about material selection based on their actual properties

Reduce the risk of material failure and optimize material performance

Improved Product Design

Create products that meet or exceed customer expectations

Increase customer satisfaction and loyalty with reliable materials

Increased Efficiency

Streamline your production process by selecting materials with known properties

Minimize waste and reduce costs associated with material failure

Key Benefits of Eurolabs Innovations in Tensile Strength Measurement Techniques

Improved Material Safety Our advanced techniques ensure accurate measurements, reducing the risk of material failure.

Enhanced Product Performance With precise tensile strength data, you can optimize material properties for specific uses.

Increased Efficiency Streamline your production process by selecting materials with known properties.

Cost Savings Reduce costs associated with material failure and rework.

Competitive Advantage Stay ahead of the competition by relying on accurate and reliable material property data.

QA Section

What types of materials can Eurolab measure for tensile strength?

Eurolab specializes in measuring the tensile strength of a wide range of materials, including metals, plastics, fibers, composites, and more.

How do you ensure accuracy in your measurements?

Our state-of-the-art equipment and expert analysis guarantee precise and reliable measurements. We also adhere to international standards for testing and calibration.

What kind of sample preparation is required for tensile strength measurement?

Sample preparation requirements vary depending on the material type and measurement technique used. Our experienced technicians will guide you through the process and ensure that your samples are prepared correctly.

Can I get a certificate or report of my materials tensile strength?

Yes, Eurolab provides comprehensive reports and certificates for all our measurements, including detailed data and analysis.

How long does it take to receive results?

Turnaround times vary depending on the complexity of the measurement. However, we strive to provide results within 24-48 hours.

Can I schedule a consultation or request a quote for your services?

Please contact us through our website or email us directly to discuss your project requirements and obtain a quote.

In conclusion, Eurolabs Innovations in Tensile Strength Measurement Techniques are designed to meet the evolving needs of businesses operating in various industries. By leveraging our expertise and cutting-edge technology, you can ensure accurate material property data, enhance product performance, and increase efficiency. Trust Eurolab for all your tensile strength measurement needs contact us today to discover how we can support your business success!