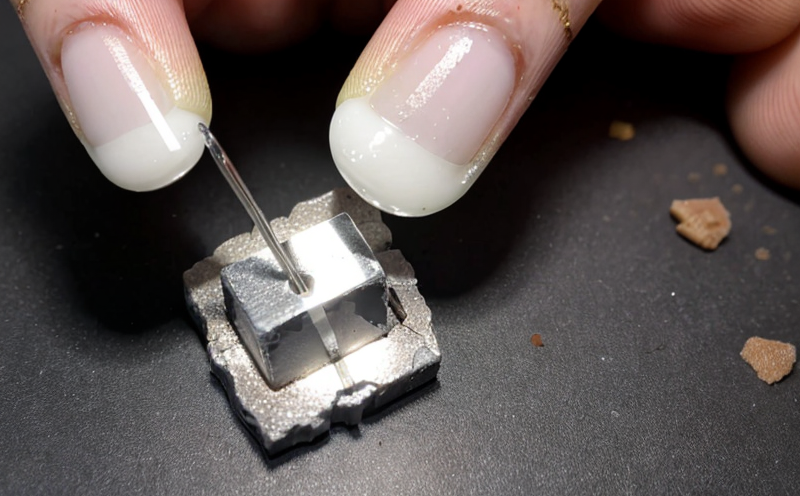

CTOD (crack tip opening displacement) testing

Unlocking Material Strength The Importance of CTOD Testing in Ensuring Product Reliability

In the fast-paced world of manufacturing and engineering, ensuring the reliability and durability of materials is crucial for businesses to stay ahead of the competition. One critical aspect of material evaluation is crack tip opening displacement (CTOD) testing, a laboratory service provided by Eurolab that helps manufacturers understand the mechanical properties of their products.

What is CTOD Testing?

CTOD testing measures the critical stress intensity factor at the tip of a pre-cracked specimen under monotonic loading. Its an essential parameter in determining the fracture toughness of materials, which is vital for predicting the performance of components under various environmental and operational conditions. By analyzing the CTOD value, manufacturers can gain valuable insights into the materials susceptibility to crack propagation and subsequent failure.

Why is CTOD Testing Essential?

In todays competitive market, product reliability and consistency are paramount. Companies that fail to meet these expectations risk losing customers, facing costly recalls, or even being shut down due to safety concerns. Eurolabs CTOD testing service provides businesses with a thorough understanding of their material properties, enabling them to

Predict component failure By evaluating the fracture toughness of materials, manufacturers can anticipate potential failure points and take corrective measures to prevent catastrophic events.

Optimize product design With accurate CTOD values, engineers can refine product designs to minimize the risk of crack propagation and maximize overall performance.

Ensure regulatory compliance Eurolabs CTOD testing helps businesses meet industry standards and regulations, reducing the likelihood of costly fines or penalties.

Reduce material waste By selecting materials with optimal fracture toughness, manufacturers can minimize material losses due to premature failure.

Benefits of Using CTOD Testing

The advantages of incorporating CTOD testing into your quality control protocols are numerous

Enhanced product reliability Accurate CTOD values ensure that products meet or exceed performance expectations.

Improved safety By identifying potential weaknesses, companies can take proactive steps to prevent accidents and injuries.

Increased efficiency Optimized material selection reduces the need for costly redesigns or rework.

Compliance with industry standards Eurolabs CTOD testing meets or exceeds international standards, ensuring your products meet regulatory requirements.

CTOD Testing Applications

Eurolabs CTOD testing services are applicable to a wide range of industries and materials, including

Aerospace Evaluate the fracture toughness of critical components in aircraft and spacecraft.

Energy Assess the reliability of equipment and piping systems used in power generation and transmission.

Automotive Test the durability of automotive parts, such as engine blocks and gearboxes.

Chemical processing Determine the material properties required for equipment handling corrosive substances.

QA Your CTOD Testing Questions Answered

What is the purpose of CTOD testing?

CTOD testing measures the critical stress intensity factor at the tip of a pre-cracked specimen under monotonic loading, providing insights into material fracture toughness.

How does CTOD testing differ from other fracture mechanics tests?

Unlike other methods, CTOD testing directly measures the critical stress intensity factor (KIC) and provides information on the materials resistance to crack propagation.

What are the advantages of using Eurolabs CTOD testing service?

Our team of experts provides accurate and reliable results, meeting or exceeding international standards. We offer a wide range of services, including sample preparation and analysis.

Can I trust the results from Eurolabs CTOD testing service?

Yes! Our state-of-the-art facilities and experienced staff ensure that every test is performed with precision and accuracy.

Conclusion

In an industry where material reliability and durability are paramount, Eurolabs CTOD testing service provides businesses with a valuable tool for optimizing product performance. By understanding the fracture toughness of materials, manufacturers can predict component failure, optimize product design, ensure regulatory compliance, and reduce material waste. Dont risk your businesss reputation choose Eurolabs expert CTOD testing services to unlock the full potential of your products.