Fracture toughness testing of metallic materials

Unlocking the Secrets of Metallic Materials The Importance of Fracture Toughness Testing

As industries continue to push the boundaries of innovation and efficiency, the demand for high-quality materials has never been greater. For businesses involved in the development, production, and distribution of metallic materials, ensuring the integrity and reliability of these materials is crucial. One critical aspect of material evaluation that cannot be overlooked is fracture toughness testing. This laboratory service, offered by Eurolab, provides unparalleled insights into the behavior of metallic materials under stress, enabling companies to optimize their products, reduce costs, and stay ahead of the competition.

What is Fracture Toughness Testing?

Fracture toughness testing measures the ability of a material to resist the propagation of cracks or fractures. It assesses the energy required for crack growth, providing valuable information on the materials susceptibility to brittle fracture. This testing method is essential in various industries, including aerospace, automotive, construction, and energy, where materials are subject to high stresses, loads, and temperatures.

Why Fracture Toughness Testing Matters

In todays fast-paced business environment, companies cannot afford to compromise on material quality or safety. Fracture toughness testing offers numerous benefits that can have a significant impact on operations

Improved Material Selection By understanding the fracture toughness of different materials, businesses can make informed decisions when selecting suitable materials for their products.

Enhanced Product Reliability Knowing how materials will perform under stress enables companies to design and manufacture more reliable products, reducing the risk of failures and associated costs.

Increased Safety Fracture toughness testing helps prevent accidents and injuries by identifying materials that may be prone to brittle fracture, ensuring a safer working environment for employees and users.

Reduced Costs By selecting materials with optimal fracture toughness, companies can minimize material waste, reduce production downtime, and avoid costly repairs or replacements.

Advantages of Fracture Toughness Testing

Eurolabs fracture toughness testing services offer numerous advantages that set us apart from other laboratory providers

Comprehensive Reporting Our expert technicians provide detailed reports on test results, including analysis and recommendations for material selection or modification.

State-of-the-Art Equipment We utilize the latest technology and equipment to ensure accurate and reliable test results.

Rapid Turnaround Times Eurolabs experienced team works efficiently to minimize testing times, ensuring you receive your results quickly without compromising on quality.

ISO/IEC 17025 Accreditation Our laboratory is accredited to ISO/IEC 17025, guaranteeing that our tests meet the highest international standards for competence and performance.

How Does Fracture Toughness Testing Work?

The fracture toughness testing process involves several steps

Material Selection We work with you to select the most suitable test specimen, taking into account material composition, dimensions, and any specific requirements.

Test Preparation Our technicians prepare the test specimens according to established protocols, ensuring accurate and reliable results.

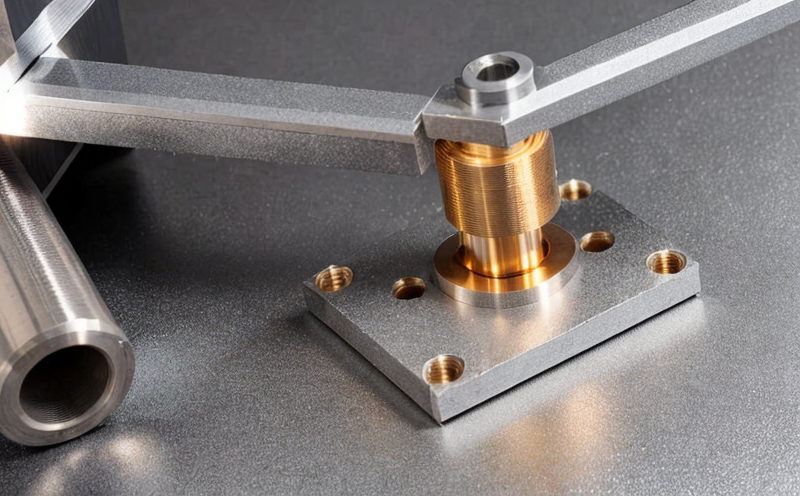

Testing The fracture toughness testing is conducted using specialized equipment, such as notched bars or compact tension specimens.

Data Analysis We analyze the test data, providing detailed reports on material performance, including energy absorbed during crack growth.

Frequently Asked Questions

Q What types of materials can be tested for fracture toughness?

A Our laboratory specializes in testing various metallic materials, including steel, aluminum, titanium, and others.

Q How long does the testing process typically take?

A Testing times vary depending on material complexity and test requirements. However, we strive to deliver results within a reasonable timeframe.

Q What is the significance of fracture toughness in industries like aerospace or automotive?

A Fracture toughness is critical in these industries, as materials are subject to high stresses, loads, and temperatures, making it essential to understand their ability to resist crack propagation.

Q Can Eurolab provide customized testing protocols for specific material applications?

A Yes, our experienced team can develop tailored testing protocols to meet the unique requirements of your project or product.

Conclusion

In conclusion, fracture toughness testing is a vital aspect of material evaluation that cannot be overlooked by businesses involved in the development, production, and distribution of metallic materials. By partnering with Eurolab, companies can benefit from our comprehensive laboratory services, including state-of-the-art equipment, rapid turnaround times, and expert analysis. Dont compromise on material quality or safety choose Eurolab for your fracture toughness testing needs and unlock the full potential of your products.