Fracture toughness of materials with low ductility

The Unseen Threat Understanding Fracture Toughness of Materials with Low Ductility and Why Your Business Needs It

In the world of materials science, there are numerous factors that can affect the performance and reliability of a material. Among these, fracture toughness is a critical property that determines how well a material resists cracking and shattering under stress or impact. However, for materials with low ductility, fracture toughness becomes an even more pressing concern. This is because low-ductile materials are prone to sudden and catastrophic failures, which can have devastating consequences for businesses.

At Eurolab, we understand the importance of fracture toughness in ensuring material reliability and safety. Our laboratory services provide comprehensive testing and evaluation of materials with low ductility, helping businesses like yours make informed decisions about their products and operations. In this article, well delve into the world of fracture toughness, exploring its significance, advantages, and applications.

What is Fracture Toughness?

Fracture toughness is a measure of a materials ability to resist crack growth and propagation under stress or impact. Its a critical property that determines how well a material can absorb energy without failing catastrophically. In simple terms, fracture toughness is the strength of a materials resistance to cracking.

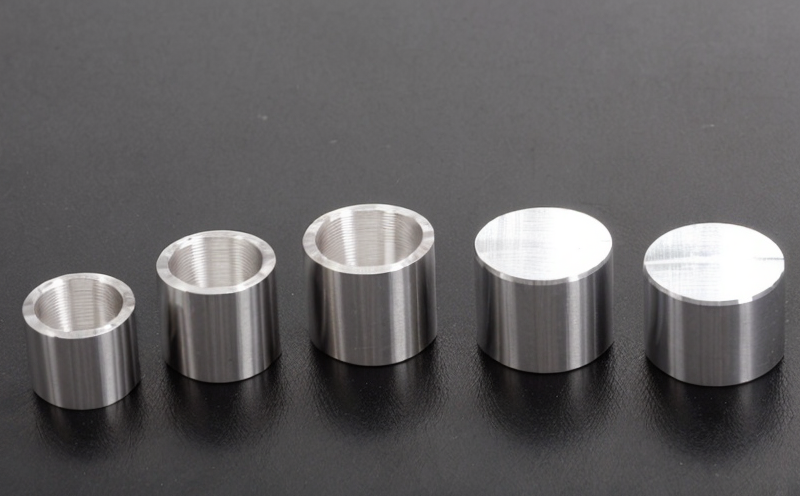

Materials with high ductility, such as copper or aluminum, are generally more resistant to cracking and shattering than those with low ductility, like steel or titanium. However, even ductile materials can become brittle under certain conditions, such as extreme temperatures or high-stress loading. This is where fracture toughness becomes a vital consideration.

Why Fracture Toughness of Materials with Low Ductility Matters

Materials with low ductility are particularly susceptible to sudden failures, which can have significant consequences for businesses. Here are just a few reasons why fracture toughness of materials with low ductility matters

Improved Safety By understanding the fracture toughness of your materials, you can identify potential failure points and take steps to mitigate risks.

Increased Reliability Comprehensive testing and evaluation of material properties ensure that your products meet or exceed performance expectations.

Cost Savings Avoid costly failures and downtime by identifying and addressing potential issues before they occur.

Enhanced Productivity With a deeper understanding of material behavior, you can optimize production processes and workflows to maximize efficiency.

Key Benefits of Fracture Toughness Testing

At Eurolab, we offer comprehensive fracture toughness testing services that help businesses like yours make informed decisions about their materials. Here are just a few key benefits of our services

Precise Material Characterization Our state-of-the-art equipment and experienced technicians provide accurate and reliable results.

Comprehensive Testing Protocols We adhere to industry-standard testing protocols, ensuring that your results are consistent and comparable to other sources.

Expert Interpretation Our team of materials scientists and engineers provides expert interpretation of test results, helping you understand the implications for your business.

Customized Solutions We work with you to develop tailored testing programs that meet your specific needs and goals.

QA Frequently Asked Questions About Fracture Toughness

Weve compiled a list of frequently asked questions about fracture toughness to help address common concerns

Q What is the difference between fracture toughness and ductility?

A Ductility refers to a materials ability to deform without cracking or shattering, while fracture toughness measures a materials resistance to crack growth and propagation.

Q Why are materials with low ductility more prone to failure?

A Low-ductile materials have limited ability to absorb energy before failing catastrophically, making them more susceptible to sudden failures.

Q Can any laboratory perform fracture toughness testing?

A While some laboratories may offer basic testing capabilities, specialized equipment and expertise are required for comprehensive fracture toughness evaluation. At Eurolab, our team of experienced materials scientists and engineers ensures accurate and reliable results.

Q What types of materials benefit from fracture toughness testing?

A Any material with low ductility, such as steel or titanium, benefits from fracture toughness testing to ensure safety and reliability.

Conclusion

Fracture toughness is a critical property that determines the performance and reliability of materials, especially those with low ductility. At Eurolab, we understand the importance of comprehensive testing and evaluation in ensuring material safety and reliability. By partnering with us, businesses like yours can make informed decisions about their products and operations, reducing risks and improving productivity.

Dont wait until its too late schedule a consultation with our team today to learn more about how Eurolab can help you navigate the complexities of fracture toughness testing.

Stay Ahead of the Curve Expert Insights from Eurolab

At Eurolab, were dedicated to providing cutting-edge laboratory services that meet the evolving needs of businesses like yours. Our experienced team is always available to answer your questions and provide expert insights on material properties and behavior. Contact us today to learn more about how we can help you stay ahead of the curve.

By choosing Eurolab for your fracture toughness testing needs, youre ensuring that your business benefits from

Comprehensive testing and evaluation

Expert interpretation of results

Customized solutions tailored to your needs

Trust Eurolab to provide the accuracy and reliability you need to make informed decisions about your materials. Schedule a consultation today!